KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825The manufacturing process of plastic injection molds is a complex and delicate process, especially in the manufacturing of PEI injection molds, which involves mold design, processing, assembly and debugging. This article will give you a detailed introduction to the manufacturing process of PEI injection molds, and strive to fully explain the knowledge in this field. If you are interested in PEI injection molding and want to get more information about PEI injection molds, welcome to consult KRMOLD! Here we have the most professional team to answer any questions you have about PEI injection molds and PEI injection molding. |  |

| 1 | Mold Design |

| 2 | Mold Processing |

| 3 | Mold Assembly |

| 4 | Mold Debugging |

| 5 | Mold Maintenance |

1. Mold Design

Mold design is a key step in the manufacture of PEI injection molds. At this stage, it is necessary to comprehensively consider the PEl injection molding process and mold manufacturing process according to the shape, size and requirements of the product, and design a reasonable mold structure and part layout. Mold design should not only focus on the complexity of the product shape, but also consider the fluidity of the material, PEI injection molding process parameters and the cooling system of the mold.

Specifically, the design of PEI injection molds needs to pay special attention to the characteristics of PEI materials. PEI (polyetherimide) is a high-performance thermoplastic with excellent high temperature resistance and chemical stability. Therefore, when designing the PEl injection molds, it is necessary to ensure that the PEl injection molds can withstand high temperatures and has good thermal conductivity to ensure the quality and consistency of PEI injection molding.

In addition, mold design also needs to take into account factors such as the mold parting line, exhaust system and PEI injection molding machine. All of these directly affect the success rate of PEI injection molding and the appearance and performance of the final product.

2. Mold Processing

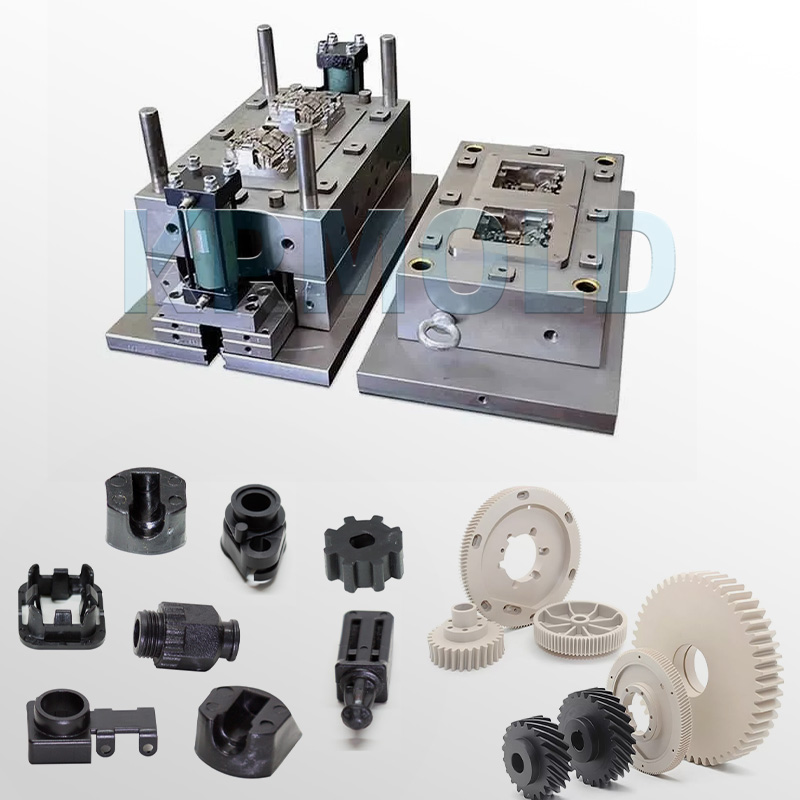

Mold processing is the processing and manufacturing of mold parts according to the design drawings. This process usually includes milling, turning, drilling, grinding and other processes. First, determine the required mold parts according to the design drawings and mold structure, and select appropriate processing equipment and processes according to the characteristics of the material and processing requirements.

For PEI injection molds, the selection of materials is crucial. Usually, materials such as high-strength alloy steel are selected to ensure the durability and stability of the mold. Then, the mold parts are precisely processed by CNC machining or manual machining to ensure that the size and accuracy required by the design are met.

In PEI injection molding, the processing accuracy of the mold is particularly important due to the relatively low fluidity of the material. Otherwise, it may lead to uneven material filling during molding, affecting the quality of the final product.

3. Mold Assembly

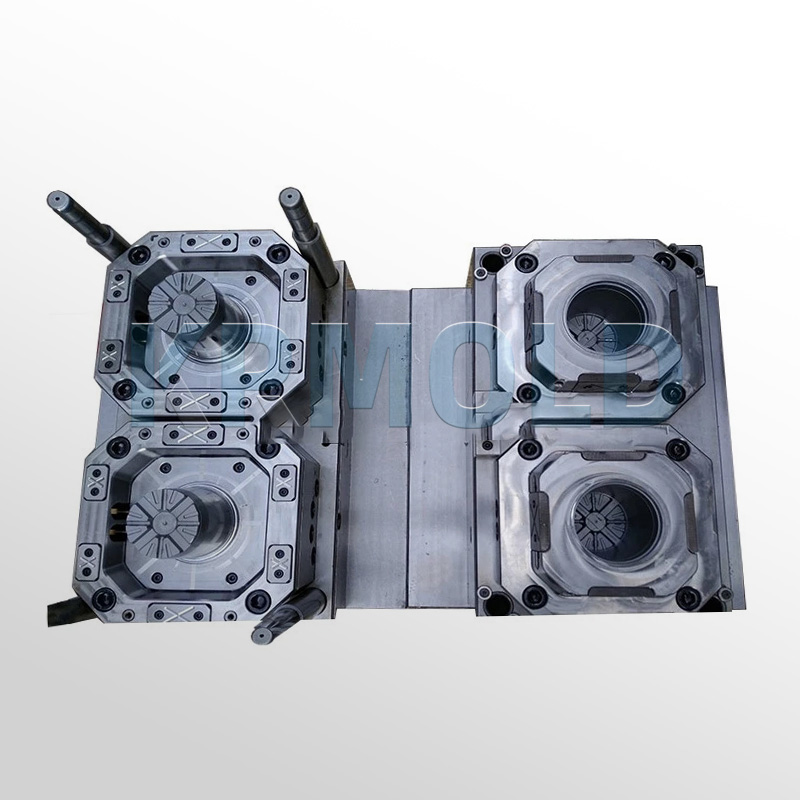

After the mold processing is completed, the mold parts need to be assembled. Mold assembly is to assemble the processed mold parts according to the design requirements to form complete PEI injection molds. During the assembly process, it is necessary to ensure the precise fit of each part to ensure the accuracy and stability of the PEl injection molds.

Especially for the installation and adjustment of the ejection, demolding and cooling systems of the PEI injection molds, special care should be taken. The effectiveness of these systems directly affects the normal operation of the mold during the injection molding process. The design of the cooling system must ensure that the mold can dissipate heat quickly and evenly to prevent the PEI material from deforming or degrading due to excessive temperature during the PEI injection molding process.

4. Mold Debugging

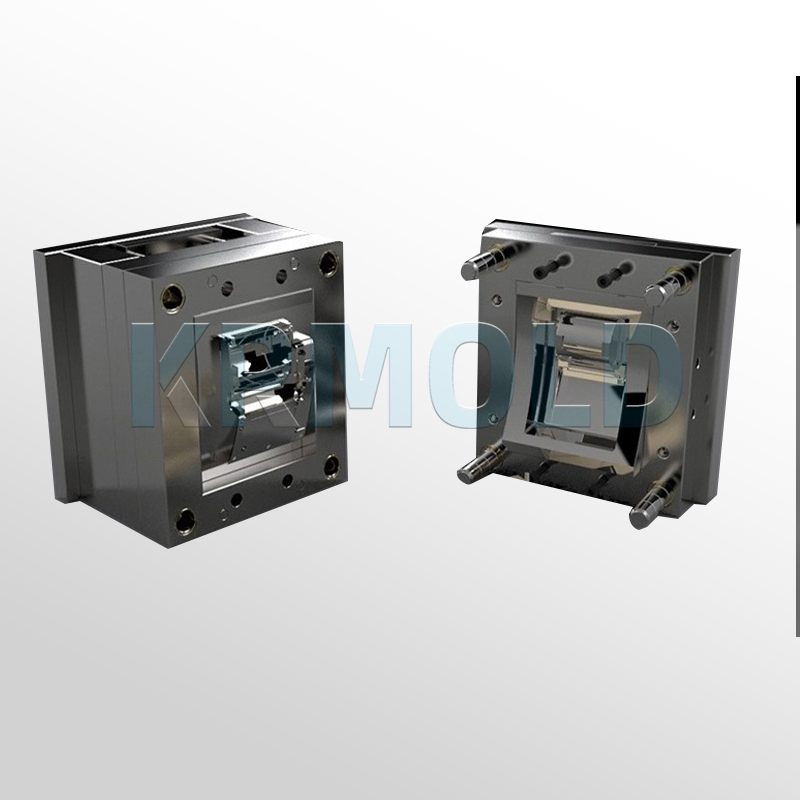

After the mold assembly is completed, mold trial and debugging are required. Mold debugging is to assemble the assembled mold to the PEI injection molding machine, and perform mold trial and adjustment to ensure the accuracy and stability of the PEl injection molds. In this process, it is necessary to adjust the PEI injection molding process parameters, mold temperature and pressure according to the actual production requirements to obtain the ideal PEI injection molding effect.

During the debugging process, recording the parameters and results of each mold trial is of great reference value for subsequent production. At the same time, it is also necessary to check and adjust the ejection, demolding and cooling systems of the PEl injection molds to ensure the integrity and smooth demolding of the product. The success of debugging is directly related to the production efficiency and product quality of the PEI injection molds.

5. Mold Maintenance

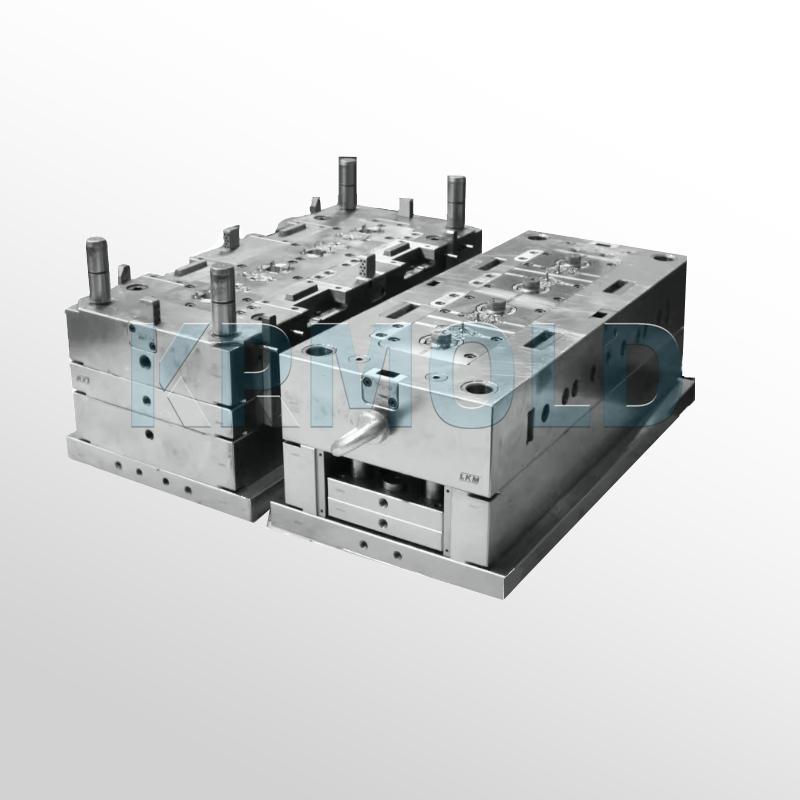

After the PEl injection molds are manufactured, it is particularly important to carry out regular maintenance and upkeep. Mold maintenance includes cleaning, lubrication, replacement of worn parts, etc. to keep the mold in normal working condition and extend the service life of the PEl injection molds. Maintenance of PEI injection molds is an important part of ensuring mold performance and production efficiency.

During the maintenance process, special attention should be paid to the cleanliness of the mold surface to prevent mold damage caused by material residue. At the same time, regular inspection and maintenance of the lubrication system can effectively reduce mold wear and ensure that it still maintains good performance under high-intensity use.