KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content:

1.General Service Life of Car Bumper Injection Molds

2.Factors Affecting Service Life of Car Bumper Injection Molds

3.Cleaning Methods Car Bumper Injection Molds

4. Maintenance and Care of Car Bumper Injection Mold

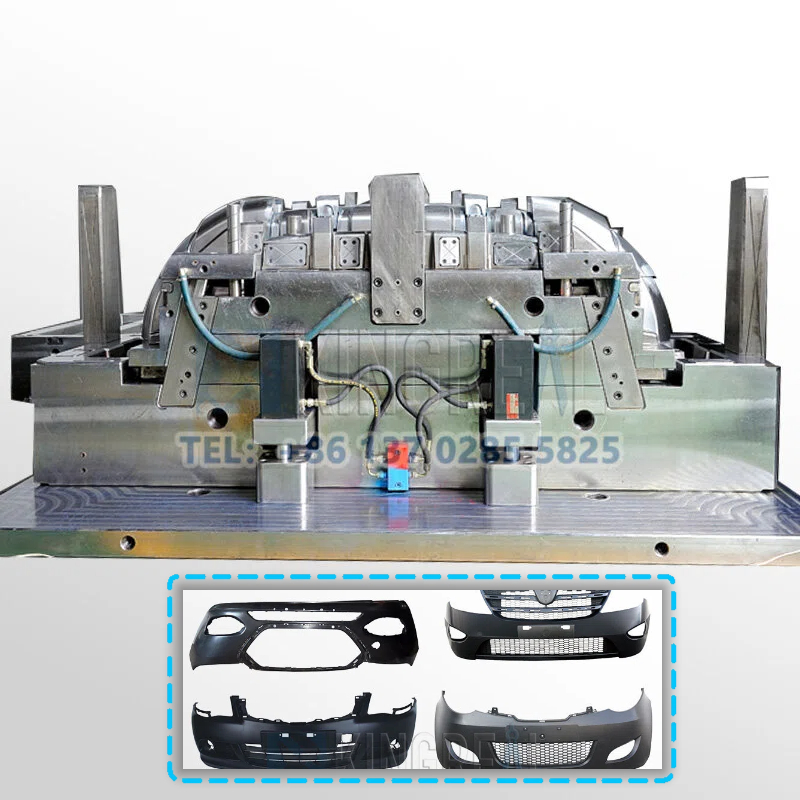

Car bumper injection molds are one of the key pieces of equipment used for the efficient production of car bumpers. As an important component of a vehicle, the bumper must not only withstand external impacts but also meet the overall aesthetic and safety requirements of the car. So, what is the service life of car front bumper injection mould? What factors affect the car bumper injection mold's service life? This article from KRMOLD will provide a comprehensive analysis.

1.General Service Life of Car Bumper Injection Molds

The service life of car front bumper injection mould is typically set between 300,000 and 1,000,000 cycles, depending on various factors such as the car bumper injection mold's material, design, production process, and operating environment. -P20 Mold Steel: Car bumper injection molds made of this material typically achieve a service life of 300,000 cycles, suitable for medium-demand production. -1.2738 Mold Steel: Car front bumper injection mould made of this material can have a service life extended to 500,000 cycles, capable of withstanding higher production intensity. -H13 and 1.2344 mold steels: These steels offer excellent car bumper injection mold wear resistance, typically achieving 800,000 to 1,000,000 cycles, making them ideal for high-load, high-intensity production environments. |  |

2.Factors Affecting Service Life of Car Bumper Injection Molds

2.1 Material Selection

The quality of the mold material is fundamental to its service life. Good materials greatly increase the resistance to corrosion and wear resistance of car front bumper injection mould. Choosing the appropriate material is hence of utmost importance to guarantee the life span of the car bumper injection mold.

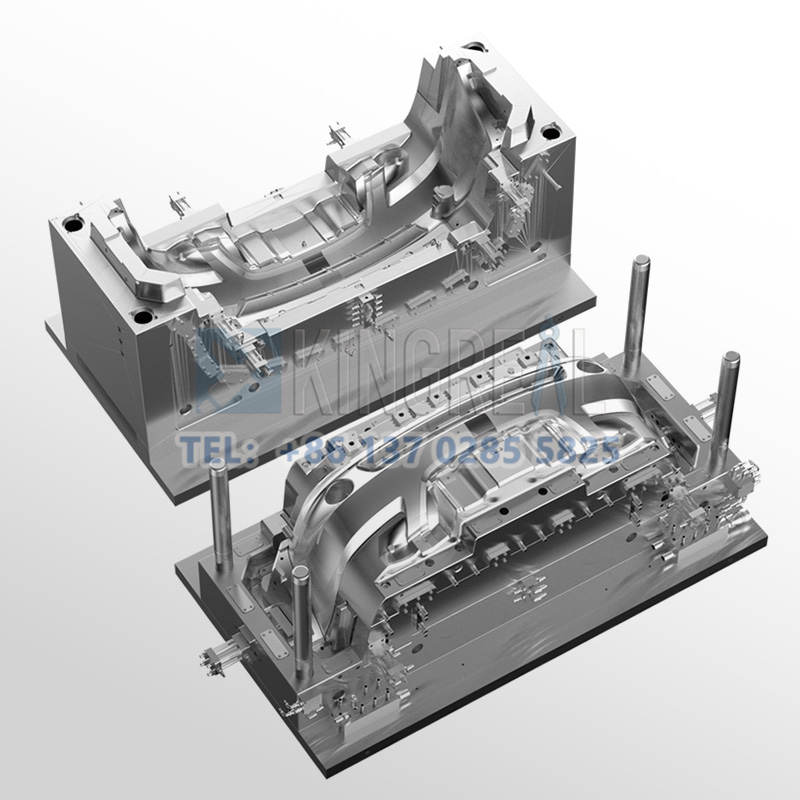

2.2 Design and Manufacturing Quality

Performance of the automobile front bumper is directly influenced by its design structure and manufacturing process. A well-designed car bumper injection mold minimizes stress concentration and improves durability. Precision manufacturing processes ensure the car front bumper injection mould’ accuracy and stability.

2.3 Operating Environment

The operating environment of automotive bumper injection molds, including temperature and humidity, affects their lifespan. For example, in humid environments, car front bumper injection mould may rust more easily, shortening their lifespan.

2.4 Injection Molding Process

A proper injection molding process can effectively reduce car bumper injection mold wear. Optimized injection parameters, such as injection speed and pressure, can reduce stress during production and extend car front bumper injection mould life.

2.5 Maintenance and Upkeep

Regular maintenance and upkeep are crucial for extending the lifespan of car bumper injection molds. Timely cleaning, lubrication, and rust prevention can effectively prevent car front bumper injection mould damage and aging.

2.6 Usage Frequency

The frequency of car bumper injection mold use is another factor directly affecting its lifespan. Higher usage frequency leads to more severe wear and tear. Therefore, frequently used car front bumper injection mould may experience fatigue more quickly.

3.Cleaning Methods Car Bumper Injection Molds

Effective cleaning not only ensures the longevity of car front bumper injection mould but also improves production efficiency. Here are some cleaning methods:

3.1 Dry Ice cleaning for car bumper injection mold

This efficient cleaning method uses compressed air to accelerate and impact dry ice particles onto the car bumper injection mold surface, quickly removing dirt and oil stains. It does not require mold disassembly, reducing downtime costs.

3.2 Manual cleaning for car front bumper injection mould

Manual cleaning is a traditional method. While it can remove simple dirt, it is labor-intensive, costly, and difficult to clean hard-to-reach areas of the car front bumper injection mould.

3.3 Laser cleaning for car bumper injection mold

Laser cleaning uses high-energy lasers to break down contaminants on the car bumper injection mold surface. This method is suitable for large car front bumper injection mould, but its effectiveness is limited for car front bumper injection mould with complex structures.

3.4 Electrolytic cleaning for car bumper injection mold

Electrolytic cleaning combines electrolysis and ultrasonic cleaning, thoroughly removing dirt from the car bumper injection mold surface and is suitable for precision car front bumper injection mould. However, it consumes more electricity and has higher operating costs.

3.5 Chemical cleaning for car bumper injection mold

Chemical cleaning uses chemical agents to decompose contaminants on the car bumper injection mold surface and is suitable for heavily contaminated molds. However, it requires professional operation and carries safety risks.

4. Maintenance and Care of Car Bumper Injection Mold

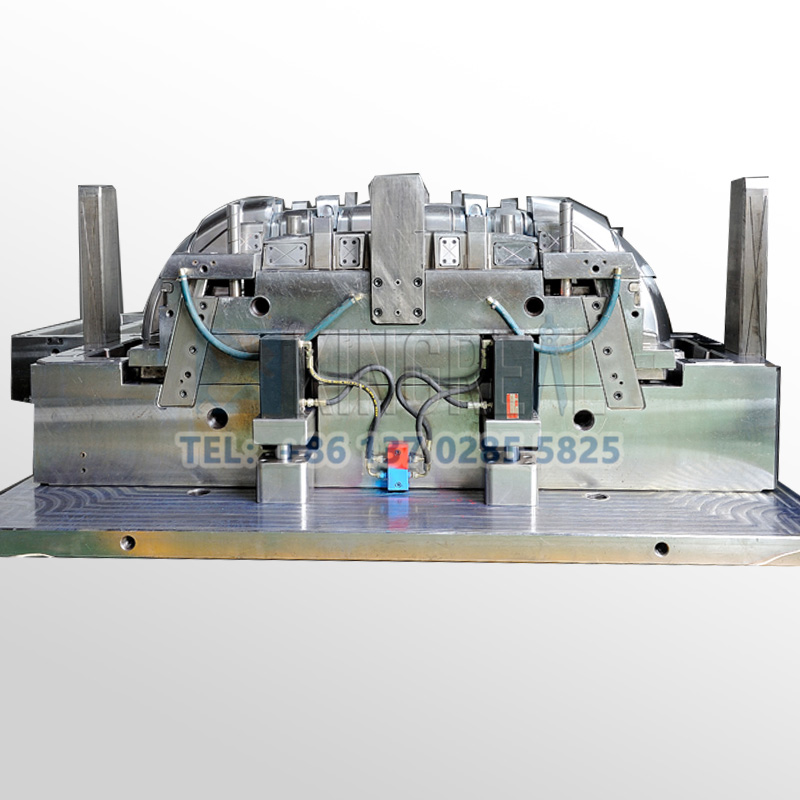

Proper maintenance and care are crucial for extending the lifespan of car front bumper injection mould. This mainly includes the following aspects:

4.1Preparation before car bumper injection mold operation

Handle the car front bumper injection mould gently while installing and removing it to avoid damage and shield the outer surface.

4.Car bumper injection mold installation and removal

When installing and removing the car front bumper injection mould, handle it gently to prevent damage and protect the outer surface.

4.3Heating and cooling control for car bumper injection mold

Proper control of the heating and cooling of the car bumper injection mold during the injection molding process is required to prevent deformation or damage brought on by excessively great or low temperatures.

4.4Regular inspection for car bumper injection mold

Regular inspections of the injection system, cooling system, and surface condition of the car front bumper injection mould will help to guarantee correct system operation. Worn components ought to be replaced right away.

4.5Precautions during injection molding

Control the injection pressure and speed, avoiding excessive pressure and speed to ensure safe car front bumper injection mould operation.

4.6Car bumper injection mold storage and maintenance

To stop rusting, car bumper injection molds should be cleaned and greased with anti-rust lubricant while they are not in use. Moreover, they ought to be kept in a proper place free from direct sunlight and humidity.