KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Basic Process of Plastic Door Shell Injection Mold Design |

| 2 | Key Points of Plastic Door Bell Injection Mold Design |

The design of plastic door bell injection molds is a complex and meticulous process involving multiple technical links.

This article by KRMOLD will delve into the key elements in the plastic door shell injection mold design, including the structural design of the plastic part, mold flow analysis, selection of injection molding machines and mold bases, as well as the design of parting surfaces, gating systems, forming parts, ejection mechanisms, and cooling systems in the mold design.

1.Basic Process of Plastic Door Shell Injection Mold Design

When designing the plastic door bell injection mold, it is first necessary to clarify the basic requirements of the plastic door shell injection mold, including the structure, size, tolerance and surface quality of the plastic part. The entire process can be divided into the following steps:

-Model establishment: Based on customer requirements and product functions, draw 3D and 2D diagrams of the door bell.

-Mold flow analysis: Professional software is used for mold flow analysis to ensure the fluidity and formability of plastics in the plastic door shell injection mold.

-Selection of injection molding machines: Choose the appropriate injection molding machine based on the design parameters of the plastic door bell injection mold.

-Mold base design: Design a mold base structure that supports the plastic door shell injection mold and ensures its stability.

-Process parameter verification: Confirm the injection molding process parameters, such as temperature, pressure and time, etc.

2.Key Points of Plastic Door Bell Injection Mold Design

(1) Model establishment for plastic door bell injection mold

Model establishment is the foundation of the entire design process. Designers need to create accurate 3D models and 2D drawings based on the functional and appearance requirements of the product. These drawings are not only used for plastic door shell injection mold production but also provide data support for subsequent mold flow analysis.

3D diagram: Shows the appearance and structure of the plastic door bell.

2D drawing: Provides detailed dimensional and tolerance information to ensure manufacturing accuracy.

(2) Parameter design of plastic parts

In the design of plastic door bell injection molds, the reasonable design of plastic part parameters is of vital importance.

(2.1) Material selection for plastic door shell injection mold

For the back cover of a door bell, choosing the right material is the key to ensuring product performance. ABS is a commonly used material due to its excellent comprehensive performance, including:

-Impact toughness: Capable of withstanding external force impacts.

-Mechanical strength: Ensures the stability of the structure.

-Dimensional stability: It is not prone to deformation after molding.

-Chemical resistance: Adaptable to various environments.

(2.2) Shrinkage rate of plastic parts

The shrinkage rate of ABS is usually between 0.004 and 0.007. This parameter needs to be taken into account during plastic door shell injection mold design to avoid dimensional instability in the finished product.

(2.3) Wall thickness of the plastic part

The wall thickness of plastic parts directly affects their strength and molding effect. Excessive wall thickness will lead to an extended cooling time and increase production costs. However, being too thin may lead to insufficient strength. According to the characteristics of ABS material, the conventional wall thickness range is 1 to 3 millimeters. After the design is completed, thickness detection should be carried out using design software to ensure it is within the allowable range.

(2.4) Draft angle for plastic door bell injection mold

The draft Angle is an important design factor to ensure the smooth demolding of plastic parts. According to the nature of ABS, the draft Angle is usually stipulated to be between 40' and 120'. A reasonable slope design can prevent plastic parts from being scratched during the demolding process.

(3) Parting surface design for plastic door shell injection mold

The parting surface is a crucial part for plastic door bell injection mold separation, and its selection directly affects the demolding of the plastic part and the structural complexity of the plastic door shell injection mold. The designer needs to draw the parting surface in the software and conduct self-intersection detection to ensure the rationality of the design.

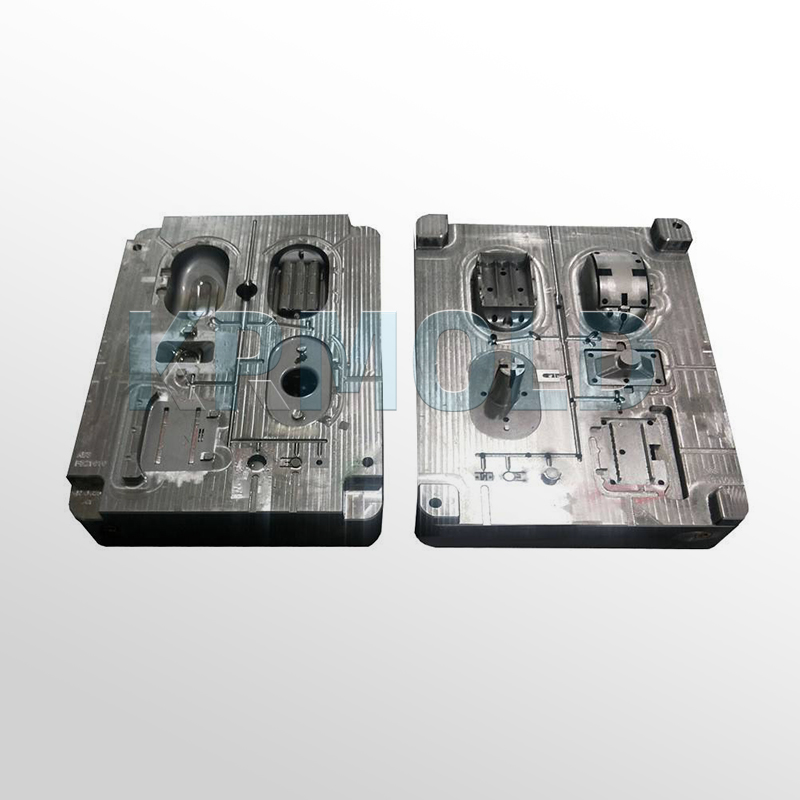

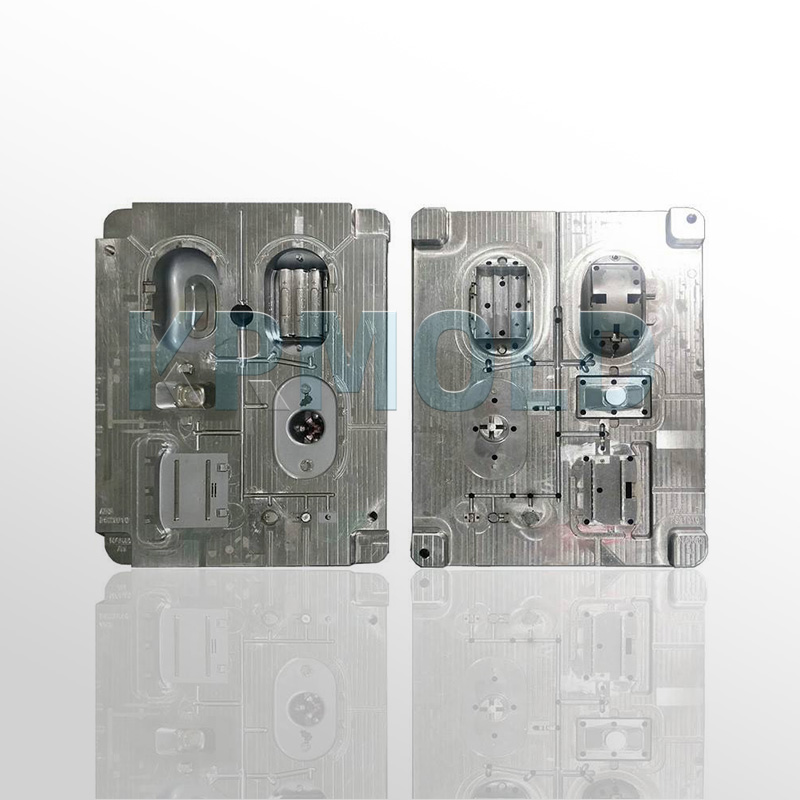

(4) Determine the number and arrangement of cavities

Due to the high appearance requirements for plastic door bell casings, a one-mold two-cavity design is usually adopted to enhance production efficiency. In addition, the slider should be taken into account in the design to avoid the gate marks affecting the appearance.

(5) Gating system design for plastic door bell injection mold

The gating system is an important part for introducing plastic materials into the mold cavity. When designing, fluidity and filling effect need to be taken into account to ensure that the plastic is evenly distributed within the plastic door bell injection mold. A reasonable design of the gating system can reduce material waste and improve production efficiency.

(6) Ejection mechanism design for plastic door shell injection mold

The ejection mechanism is used to push the plastic part out of the plastic door shell injection mold after it has been formed. When designing, the distribution of the top force should be taken into consideration to avoid damaging the surface of the plastic part.

(7) Cooling system design for plastic door bell injection mold

The design of the cooling system is crucial for enhancing production efficiency and ensuring product quality. A reasonable design of cooling channels can shorten the cooling time and increase the production cycle. The cooling system should be capable of rapidly and evenly reducing the mold temperature to ensure that the plastic part does not deform during the molding process.

The design of plastic door shell injection mold is a complex process involving multiple technical elements. Reasonable model establishment, material selection, wall thickness design, draft Angle and parting surface design, etc. are all key factors to ensure the success of the plastic door bell injection mold.

The use of modern design software for mold flow analysis and optimization can significantly enhance design efficiency and reduce production costs. With the continuous advancement of technology, the design of plastic door shell injection molds will become more refined and efficient, providing the market with higher-quality products.