KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Large Home Appliance Injection Molds for Refrigerators |

| 2 | Large Home Appliance Injection Mould for Washing Machines |

| 3 | Large Home Appliance Injection Mould in Air Conditioners |

| 4 | Large Home Appliance Injection Molds for Electric Fans |

| 5 | Large Home Appliance Injection Mould for Vacuum Cleaners |

| 6 | Large Home Appliance Injection Molds for Electric Irons |

| 7 | Large Home Appliance Injection Molds for Microwave Ovens and Rice Cookers |

As the name suggests, large home appliance injection molds are tools specifically designed for producing and manufacturing precision components for large appliances. These large home appliance injection mould are in high demand in the market due to their ability to efficiently and accurately produce a wide range of appliance components.

This article will provide a detailed introduction to the seven most commonly produced large appliances using large home appliance injection mould, providing readers with a deeper understanding of the wide range of applications for large home appliance injection molds.

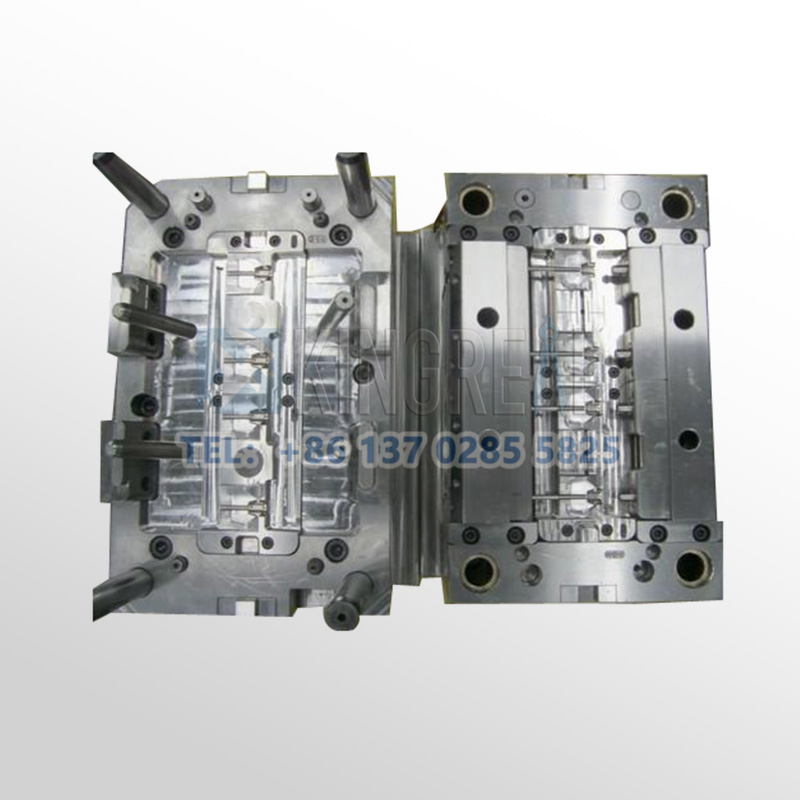

Before manufacturing plastic injection mould for large home appliance, KRMOLD typically performs mold flow analysis. This process can proactively identify potential issues during the injection molding process, such as uniform plastic flow, appropriate wall thickness, and post-molding visual defects such as bubbles, shrinkage, and weld marks. Through appropriate analysis and improvements, including material selection, gate location and number, parting line design, and verification of critical dimensions, unnecessary rework can be avoided, saving time and costs.

For large appliances, the precision of molded parts and the proper fit of component assembly are particularly important. Therefore, high-precision mold processing is essential. KRMOLD has a variety of high-precision CNC machining centers that can meet the processing needs of large home appliance injection molds. For example, its gantry CNC milling machines can reach sizes up to 4200 x 1800 mm and depths of 600-800 mm, making them suitable for manufacturing large home appliance injection mould for various applications, including air conditioner and washing machine molds. Furthermore, mold assembly must be precise, otherwise rework will be time-consuming and costly.

1. Large Home Appliance Injection Molds for Refrigerators

Refrigerators are a key application area for large home appliance injection mould. The refrigerator's exterior and internal structure typically require the following properties:

-Mechanical strength and rigidity: Ensures deformation during use.

-Dimensional stability: Ensures shape retention under varying temperatures and humidity.

-Creep resistance: Ensures long-term pressure resistance without deformation.

-Non-toxicity and odorlessness: Ensures food safety during storage.

-Resistance to low temperatures and edible oils: Adapts to the unique environment inside refrigerators.

These requirements make plastic injection molds for large home appliance particularly important in refrigerator production.

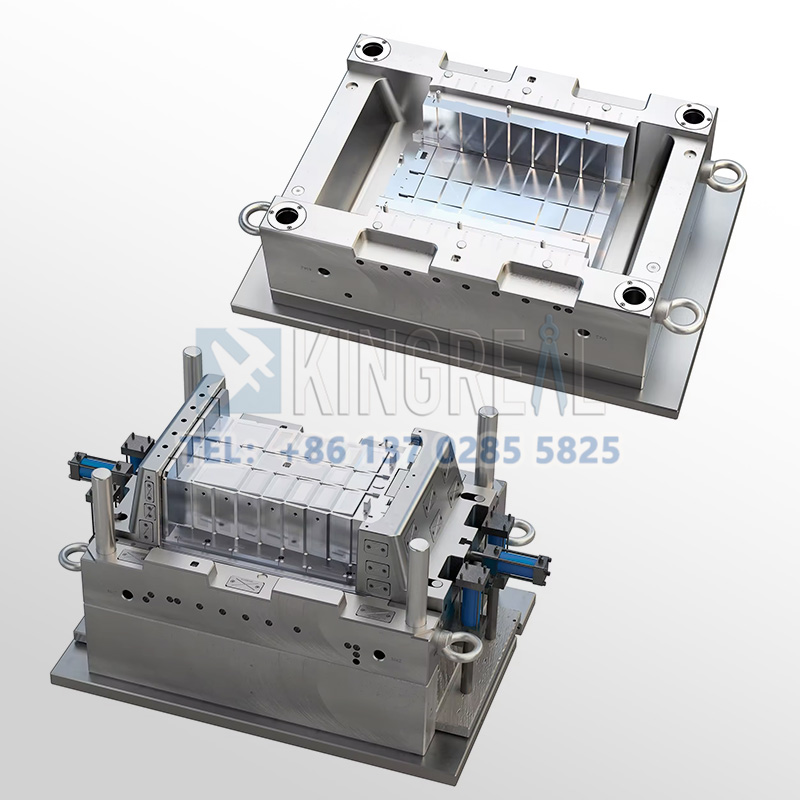

2. Large Home Appliance Injection Mould for Washing Machines

Washing machines are also widely used in plastic injection molds for large home appliance. Washing machine internal components, such as the inner tub, cover, base, and turbine, typically place high demands on mold materials:

-Heat resistance: Requires a minimum of 100°C to withstand high-temperature washing environments.

-Chemical resistance: Provides excellent resistance to detergents, lubricants, and greasy substances.

-Impact resistance: Ensures resistance to damage during use.

Common plastics used in the production of injection molds for washing machines include general-purpose plastics like PP and engineering plastics like polyoxymethylene, polyamide, and ABS.

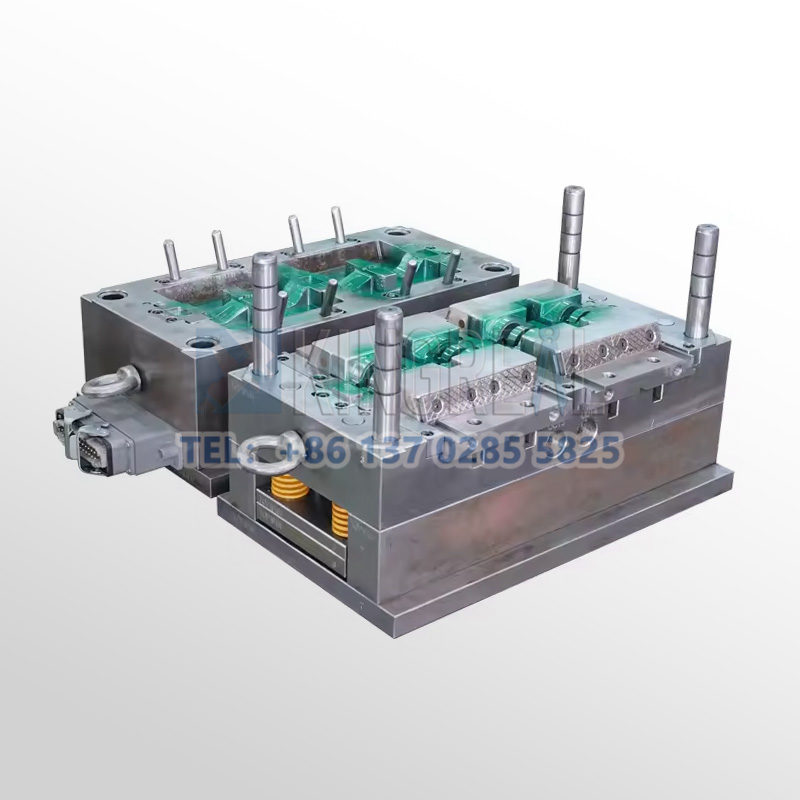

3. Large Home Appliance Injection Mould in Air Conditioners

The production of air conditioners also relies on large home appliance injection molds. Key components include fans, air intakes, control panels, and rear housings, all of which place extremely high demands on large home appliance injection mould materials:

-Rigidity and creep resistance: Ensure stability under high-temperature and high-load operating conditions.

-Flame retardancy and cold resistance: Ensure operational performance under extreme climate conditions.

-Heat deflection temperature: Requires a temperature above 70°C to ensure deformation during extended use.

Air conditioner components are typically made of reinforced materials like ABS and AS, while fans are often made of plastics with added glass fiber for increased strength and durability.

4. Large Home Appliance Injection Molds for Electric Fans

The production of electric fans also relies on large home appliance injection mould, primarily for components such as blades, blade covers, housings, and knobs:

-Material Selection: Blades are typically made of opaque ABS, while transparent blades are often made of AS.

-Impact Resistance and Glossiness: Ensure the fan's safety during use and aesthetic appearance.

These requirements make large home appliance injection molds also crucial in electric fan production.

5. Large Home Appliance Injection Mould for Vacuum Cleaners

The production of vacuum cleaners requires materials with high rigidity, impact resistance, and scratch resistance, all of which rely on the high-precision processing of large home appliance injection molds:

-Housing Material: Typically ABS, while the motor bracket and wheel accessories are often made of polyamide (PA) or reinforced PP.

-Anti-static Properties: Ensure that static electricity is not generated during use, preventing any degradation of vacuuming performance.

These characteristics make large home appliance injection mould crucial in vacuum cleaner production.

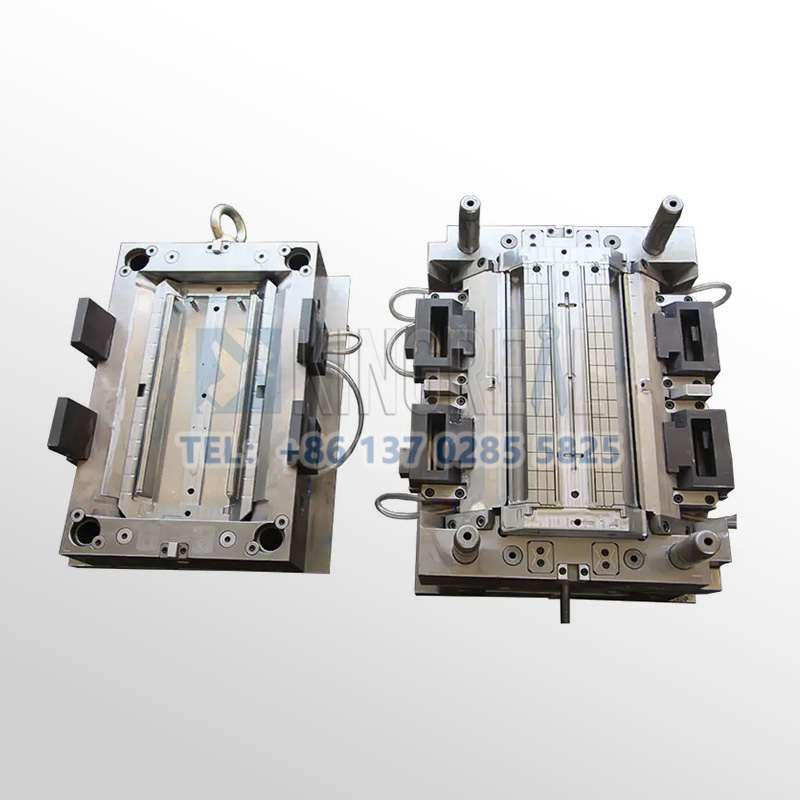

6. Large Home Appliance Injection Molds for Electric Irons

The production of electric irons also relies on plastic injection mould for large home appliance to ensure their excellent appearance and performance:

-Heat resistance and impact strength: The outer shell, handles, and sink base are typically made of reinforced PP or ABS.

-High-temperature components: Components near the heating zone require higher heat resistance, and commonly used materials include PC, PA reinforced materials, or PBT.

These requirements ensure the safety and reliability of the electric iron during use.

7. Large Home Appliance Injection Molds for Microwave Ovens and Rice Cookers

The production of microwave ovens and rice cookers places extremely high demands on material selection and large home appliance injection mould precision:

-Heat resistance and flame retardancy: Ensure safe use in high-temperature environments.

-Dimensional stability: Ensure the product does not deform during use.

The outer shell is typically made of ABS, while internal high-temperature components require high-performance materials such as glass fiber-reinforced PSF, PPS, polyetheretherketone (PEEK), and liquid crystal polymer (LCP).