KINGREAL UNIVERSAL IND., LTD

Phone

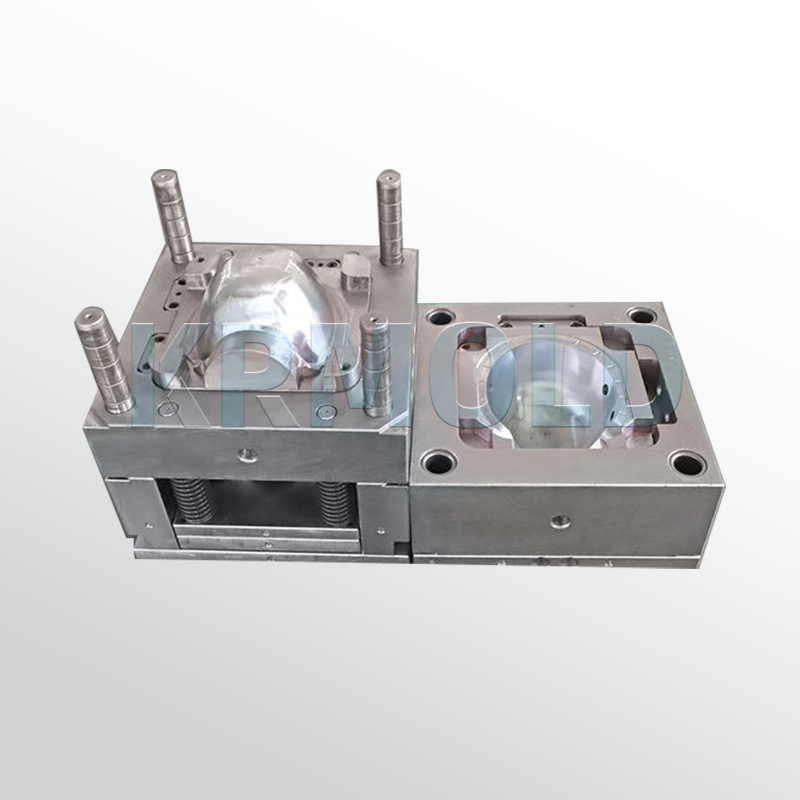

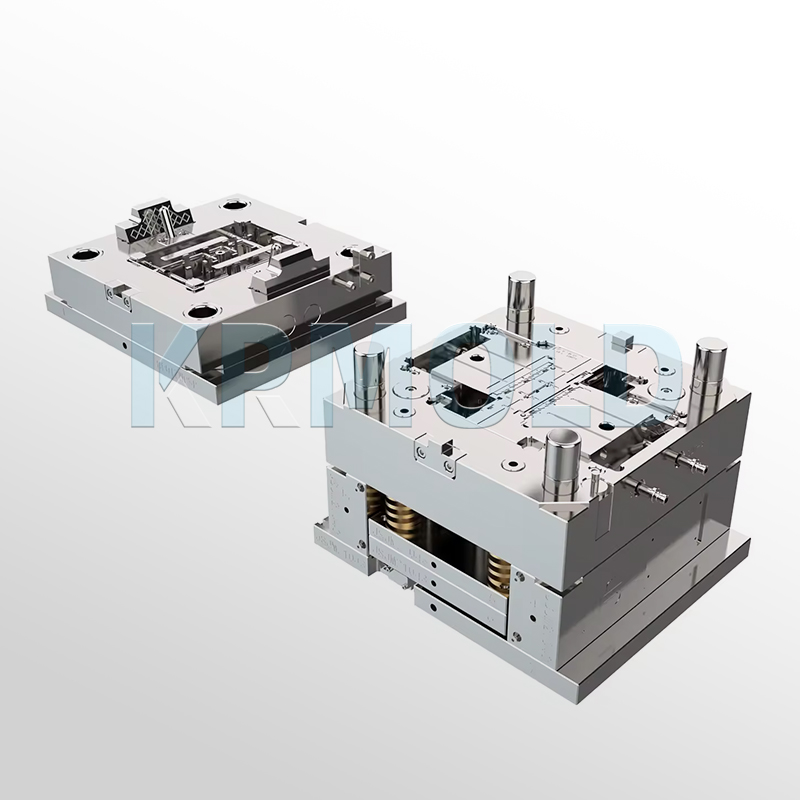

+86-13702855825PPE injection molding is an efficient and adaptable manufacturing process. It requires injecting molten material (usually durable plastic) into a mold to form the desired shape. The mold cools and hardens to form a finished product that can be used immediately or further processed. With the PPE plastic injection molding process, manufacturers can mass-produce complex and detailed products such as helmets, masks and goggles while minimizing waste. |  |

| 1 | Conditions for PPE Injection Molding |

| 2 | Advantages of PPE Injection Molding |

| 3 | Characteristics of PPE Plastic Injection Molding |

| 4 | Quality Control Methods for PPE Injection Molding |

1.Conditions for PPE Injection Molding

| Drying | It is recommended to dry at 100°C for 2 to 4 hours before processing. |

| Melting temperature | 240 to 320°C |

Mold temperature | 60 to 105°C |

Injection pressure | 600 to 1500 bar |

Runners and gates | All types of gates can be used. Particularly suitable for the use of handle gates and fan gates. |

2.Advantages of PPE Injection Molding

High-volume production: One of the biggest advantages of PPE plastic injection molding is the ability to quickly produce large quantities of PPE parts. This is critical when many people need PPE, especially during a global health crisis.

Cost-effectiveness: Although the initial setup cost of PPE plastic injection molding equipment is high, the unit cost of PPE injection molding production can decrease significantly with mass production. This makes it a very cost-effective solution for large-scale production.

Customization: Custom PPE plastic injection molding allows manufacturers to produce PPE according to specific industry standards or requirements. Modifying the mold can help produce products for different uses or meet regulatory requirements.

Reduce material waste: PPE injection molding is a very efficient process. It reduces material waste and provides a more sustainable option for large-scale production. Careful use of materials can reduce the need for additional raw materials and reduce environmental impact.

3.Characteristics of PPE Plastic Injection Molding

PPE performance characteristics:

PPE is a thermoplastic engineering plastic with excellent overall performance, outstanding in electrical insulation and water resistance, and good standard stability. Dielectric function ranks first among engineering plastics: There is no strong polar group in the molecular design of PPE resin, the electrical function is stable, and it can maintain excellent electrical function within a wide range of temperature and frequency ranges. Its dielectric constant and dielectric loss tangent are the smallest among engineering plastics, and are almost unaffected by temperature, humidity and frequency.

Its volume resistivity is the highest among engineering plastics. PPE's excellent electrical properties make it widely used in the production of electrical products, especially high-voltage resistant parts, such as the line output transformer (FBT) of color TVs. Excellent mechanical and thermal properties: PPE subchains are rich in aromatic ring structures, and the molecular chain is relatively rational. The resin has high mechanical strength, excellent creep resistance, and little effect of temperature changes. PPE has high heat resistance, with a glass transition temperature of up to 211°C and a melting point of 268°C.

Performance of PPE injection molding:

PPE can be processed by either plunger or screw injection molding machines. Generally, screw injection molding machines are used, requiring a length-to-diameter ratio greater than 15:1 and a compression ratio of 1.7 to 4.0 (generally 2.5 to 3.5); Extrusion: PPE can be processed into tubes, sheets, rods, blocks, etc. on the extruder. It is better to use a venting type extruder with a large aspect ratio, with a screw aspect ratio of 24:1, a compression ratio of 2.5-3.5, a sudden change type, equidistant and unequal depth, and a proper depth in the metering section.

Compression molding: Glass cloth soaked in a benzene solution of 10%-18% PPE can be controlled according to the lamination process conditions of thermosetting plastics. The glue content of the glass cloth is controlled at 35%±5%, and the drying temperature is 70-110℃; Molding process: When the mold temperature rises to 250℃, maintain the temperature for 5min, the pressure is 6MPa, and the temperature is continuously raised to 300℃, kept warm for 1h, and then naturally cooled to 180℃, and cooled to room temperature by cold water for demoulding. PPE can also be film-formed and processed secondary;

PPE performance has excellent physical and mechanical properties, heat resistance and electrical insulation, low hygroscopicity, high strength, and standard stability. It needs to be processed at a high temperature of 300℃.

For this reason, the PPE resin is modified by the "alloying" method of blending polystyrene or impact polystyrene. Most of the useful functions of this modified resin are preserved. Almost all the products sold on the market are alloyed products.

Because PPE alloy overcomes the disadvantage of stress cracking of PPE itself, improves the processing function of PPE, and has excellent thermal, electrical and mechanical functions. This modified polystyrene or impact polystyrene polyphenylene ether has a low glass transition temperature, is easier to process, and has no degradation. Of course, the heat resistance has dropped, but most of the useful functions of PPE resin are retained.

4.Quality Control Methods for PPE Injection Molding

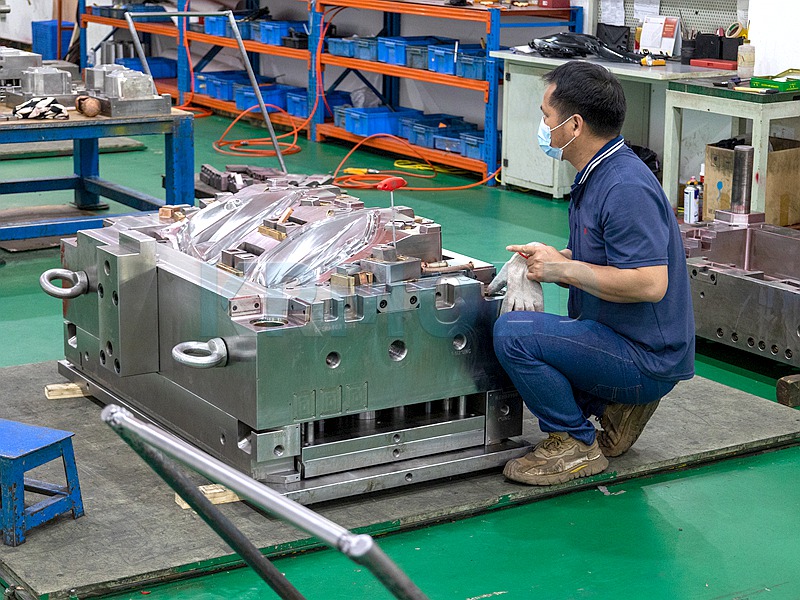

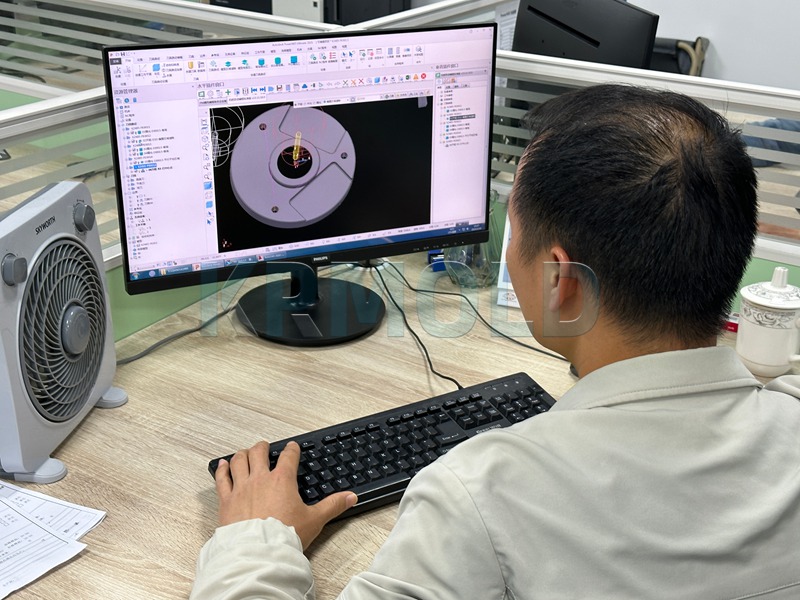

KRMOLD uses a variety of methods to maintain high standards for PPE plastic injection molding:

Material testing: Before production, the raw materials must undergo rigorous performance tests: strength, flexibility and chemical resistance. PPE such as helmets must be made of materials that can resist impact and provide protection.

Production monitoring: The quality control team monitors the production process at all stages. Regular inspections are carried out to ensure that each mold produces products according to the required specifications.

Automated inspection: Modern PPE plastic injection molding machines are equipped with automated inspection systems to detect defects during the production process. These systems are able to detect defects such as cracks, bubbles and uneven material distribution.