KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Basic Requirements for Plug Socket |

| 2 | Considerations for Material Selection of Plug Socket Plastic Injection Mold |

| 3 | Key Points for Design of Injection Mold for Electric Power Plug Socket |

| 4 | Advantages of KRMOLD Injection Mold for Electric Power Plug Socket |

The plug socket plastic injection mold is a kind of mold specifically used for manufacturing the electric power plug sockets. Since the purpose of the electric power plug socket is closely related to the power connection, its design and manufacture must meet a series of strict requirements. These requirements include good insulation, stable chemical properties, easy molding and processing, and no bending or breaking during use. In addition, the surface quality of the plastic part is also of vital importance, and it is required that there be no flash or shrinkage cavities.

In modern life, plug sockets are everywhere, whether in homes or public places, and the demand for plug sockets is very high. Therefore, the market demand for injection molds for electric power plug socket has also risen, becoming a key equipment for large-scale production. |  |

1.Basic Requirements for Plug Socket

As a protective component of electrical equipment, the electric power plug socket must possess the following basic characteristics:

-Insulation: Good insulation performance is one of the most important requirements for socket shells to ensure the safety of users.

-Chemical stability: The plug socket material must be able to resist the erosion of various chemical substances to ensure no deformation during long-term use.

-Formability: The material should be easy to form and process to enhance production efficiency.

-Impact resistance: The casing should have excellent impact resistance to cope with accidental collisions.

-Surface quality: The surface should be smooth without burrs or shrinkage cavities to enhance the product's aesthetic appeal and service life.

2.Considerations for Material Selection of Plug Socket Plastic Injection Mold

(1) Comparative analysis of the properties of commonly used plastics

When choosing plastic part materials, the usage environment and functional requirements need to be taken into consideration. For plastic parts under normal temperature working conditions, the main concerns are the mechanical properties such as the elastic modulus, yield stress, bending strength and surface hardness of the material. The selection of materials not only needs to ensure dimensional accuracy, but also take into account the ease of forming and economy.

The following is a comparison of the properties of commonly used plastics

| Material | Elastic Modulus | Yield Strength | Impact Strength | Chemical Stability | Machinability |

| ABS | High | High | Excellent | Good | Easy |

| PP | Medium | Medium | Medium | Excellent | Easy |

| PC | High | High | Excellent | Good | Easy |

(2) Material selection for plug socket plastic injection mold

According to the comparative analysis, the three materials, ABS, PP and PC, all meet the requirements for injection mold for electric power plug socket. However, considering the difficulty and economy of molding, ABS was chosen as the most ideal material.

●The characteristics of ABS material

ABS has the following advantages:

Chemical resistance: It can resist the erosion of various chemical substances.

Good impact toughness: It has excellent impact resistance and is suitable for making shells.

Dimensional stability: Under temperature changes, the dimensional variation is small and the shape remains stable.

Easy to form: It is easy to form during processing and has high production efficiency.

The application scope of ABS is very wide, including automotive parts, electrical appliance casings and daily necessities, etc.

3.Key Points for Design of Injection Mold for Electric Power Plug Socket

When designing the injection mold for electric power plug socket, multiple key elements need to be considered to ensure the high efficiency and reliability of the plug socket plastic injection mold.

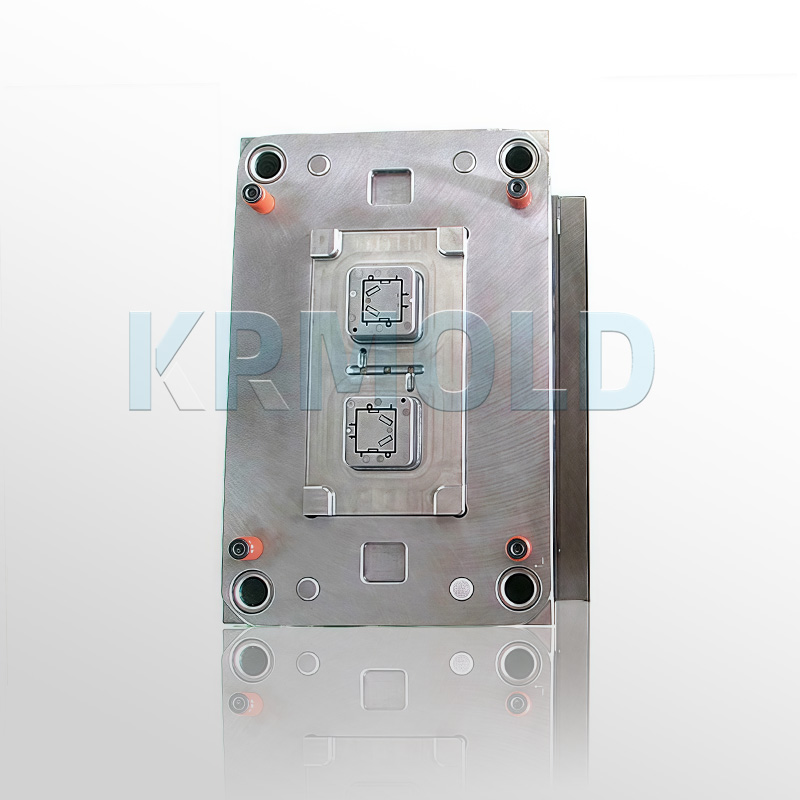

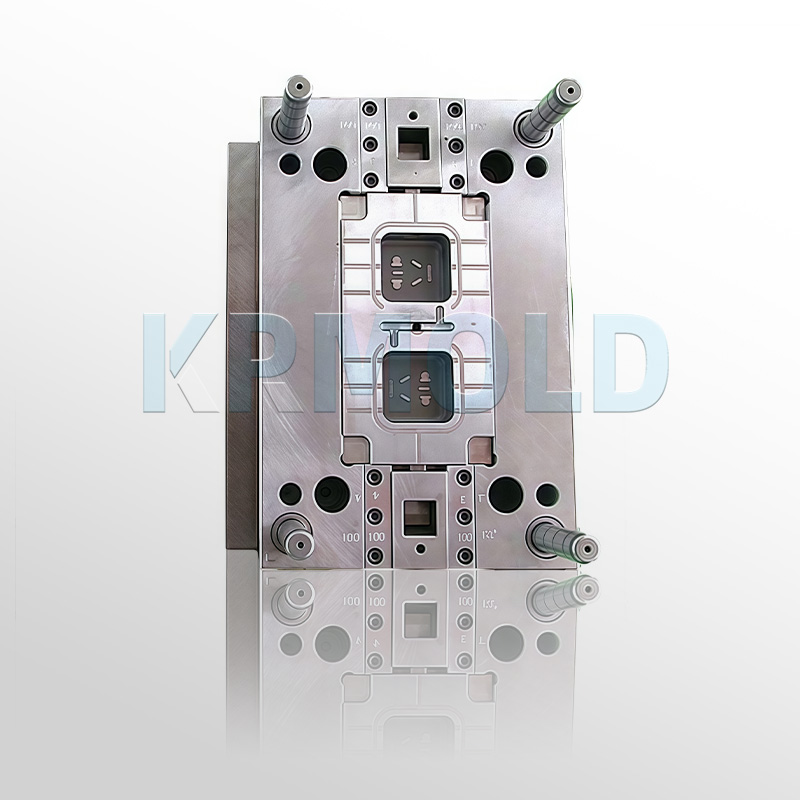

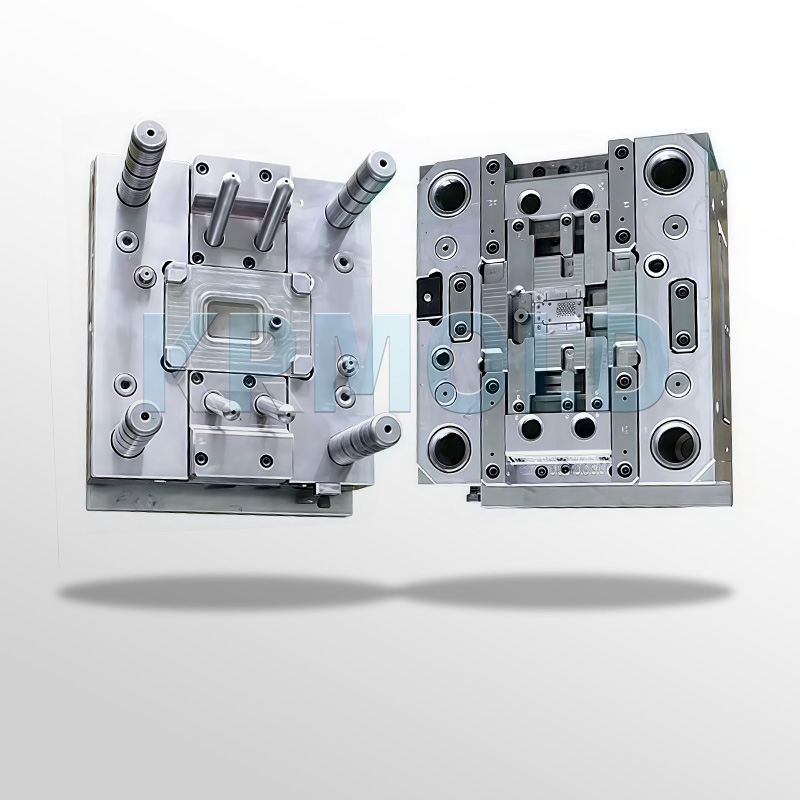

(1) Plug socket plastic injection mold structure design

The structural design of the injection mold for electric power plug socket needs to take into account the following aspects:

-Parting surface design: A reasonable parting surface design can simplify the mold structure while ensuring the smooth demolding of the plastic part.

-Gating system design: The gating system should ensure uniform flow of the plastic and avoid bubbles and defects.

-Cooling system design: An effective cooling system can shorten the molding cycle and enhance production efficiency.

(2) Injection molding process parameters

In the injection molding process, the setting of process parameters plays a crucial role in the quality of the final product. The main parameters include:

-Injection temperature: Control the molten state of the plastic to ensure smooth injection into the plug socket plastic injection mold.

-Injection pressure: Appropriate injection pressure can ensure that the plastic fully fills the cavity.

Cooling time: A reasonable cooling time can enhance production efficiency and prevent deformation.

(3) Ejection mechanism design

The ejection mechanism is responsible for ejecting the formed plastic part from the injection mold for electric power plug socket. When designing, the distribution of the top force should be taken into consideration to ensure that the plastic parts remain intact. At the same time, it is necessary to avoid scratching the surface of the plastic part during ejection.

(4) Selection of plug socket plastic injection mold materials

The selection of mold materials is equally important. Commonly used mold materials include steel and aluminum alloy. Steel has excellent wear resistance and strength, making it suitable for mass production. Aluminum alloy, on the other hand, is more suitable for small-batch production due to its high processing efficiency.

4.Advantages of KRMOLD Injection Mold for Electric Power Plug Socket

As a professional plastic injection mold manufacturer, KRMOLD offers high-quality injection mold for electric power plug sockets, featuring the following advantages:

-Fire resistance performance: Fireproof enclosures can be produced to reduce the risk of fire and ensure user safety. -Waterproof function: Designed with a waterproof casing, it is suitable for damp environments and can extend the service life. -Customized design: According to customer requirements, KRMOLD provides plug socket plastic injection molds of various shapes and sizes. -Color selection: The injection mold for electric power plug socket can be injection molded according to customer requirements to achieve a variety of products. |  |

The plug socket plastic injection mold plays an important role in modern life. With the increasing demand for electrical equipment, the production of plug socket is becoming increasingly important.

Designing and manufacturing high-quality injection mold for electric power plug sockets not only enhances production efficiency but also ensures the safety and reliability of products.

Through reasonable material selection, precise mold design and optimized injection molding process, the market prospects for plug socket plastic injection molds will be even broader. KRMOLD will continue to be committed to providing customers with high-quality injection mold for electric power plug socket solutions and promoting the development of the industry.