KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Parameters of Plastic Washing Machine Injection Mold |

| 2 | KRMOLD Technologies for Plastic Washing Machine Injection Mold Design |

| 3 | Tips for Plastic Washing Injection Machine Mold Maintenance |

| 4 | KRMOLD Plastic Washing Machine Injection Mold After-Sales Service |

| 5 | KRMOLD Plastic Washing Machine Injection Mold Rigorous Manufacturing Process |

| 6 | Why Choose KRMOLD Plastic Washing Machine Injection Molds? |

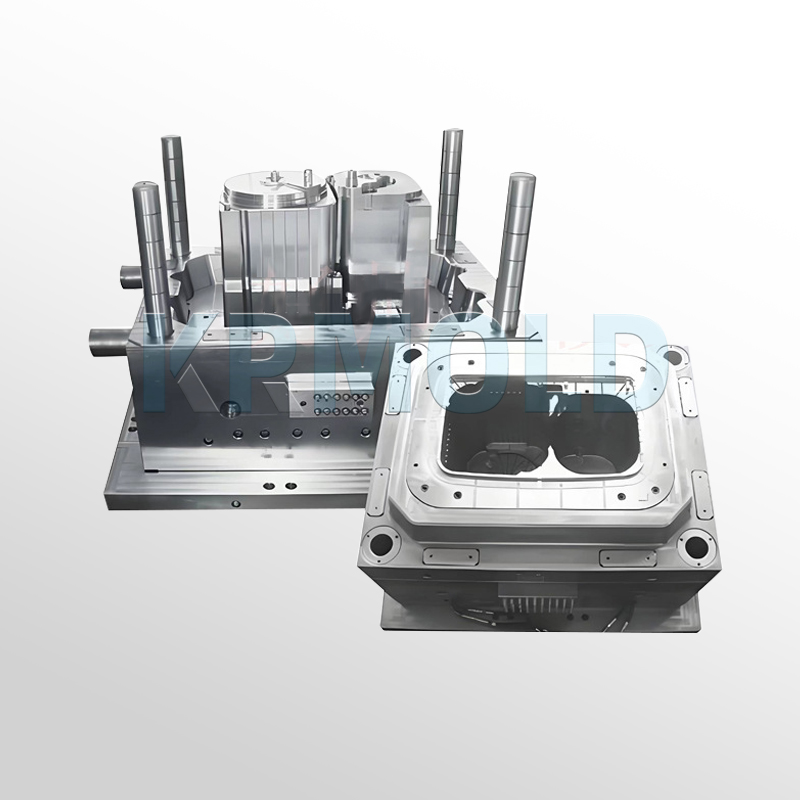

High-precision plastic injection molds meant especially for making washing machine housings are plastic washing machine injection molds. Among twin-drum and single-drum versions, they provide a range of washing machine housing styles. Plastic washing machine injection mould are becoming more and more used as the home appliance sector grows quickly and have come to be an essential part of washing machine manufacturing. High-quality plastic washing machine injection molds not only make products look better but also boost production efficiency and lower expenses. With its great quality and fair pricing, KRMOLD has gained customers’ trust as a professional plastic washing machine injection mould producer.

KRMOLD can customize a variety of plastic washing machine injection molds to meet customer needs. Whether based on drawings or samples provided by the customer, KRMOLD can design and manufacture high-precision plastic washing machine injection mould. This customized service allows KRMOLD to stand out in the competitive market and meet the specific needs of diverse customers.

1/ Parameters of Plastic Washing Machine Injection Mold

| Core and cavity steel materials | P20, 718H, 2738H, H13, NAK80, 2316, etc. |

| Mold Base and Standard Parts | DME, HASCO, Custom-Made, etc. |

| Steel Hardness | HRC 48-52 |

| Plastic Materials | PP, PC, PE, ABS, PVC, etc. |

| Cavity | Single or Customized |

| Injection System | Side Gate, Needle Gate |

| Ejector System | Ejector |

| Runner | Hot Runner, Cold Runner |

| Cycle Time | 30-120s |

| Mold Life | 500,000 Cycles |

| Quality Assurance | ISO9001 |

2/ KRMOLD Technologies for Plastic Washing Machine Injection Mold Design

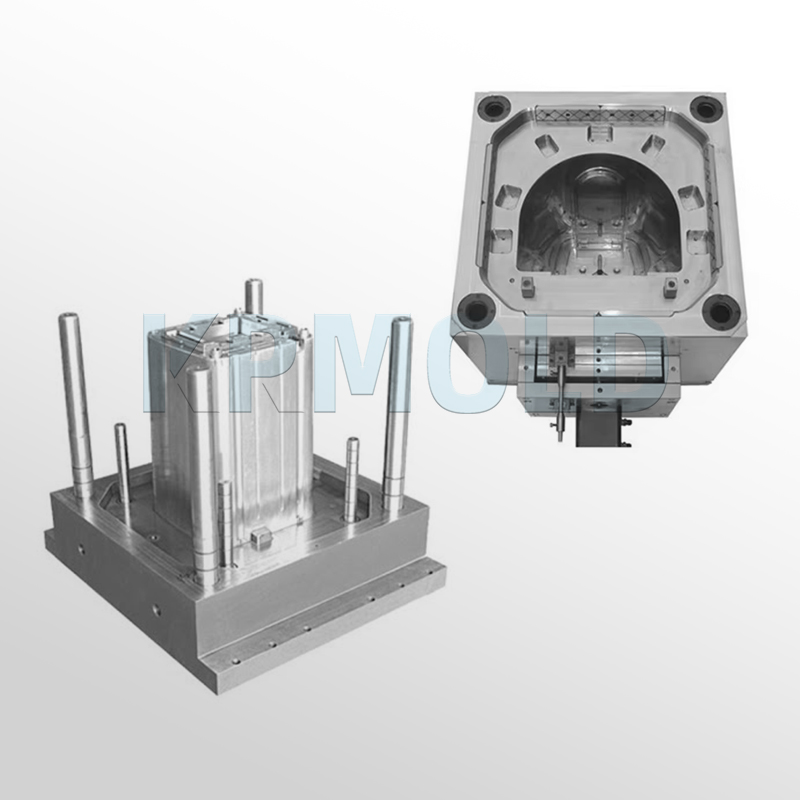

1. Plastic washing machine injection mould structure design

KRMOLD professional team of designers provides customers with optimized mold structure designs, aiming to shorten production cycles, reduce unnecessary steps, and improve production efficiency. This optimized design ensures efficient mold operation during production, ensuring final product quality.

2. Cooling system for washing machine injection mould

The mold cooling system design is crucial. KRMOLD designs optimized cooling channels, such as gates, hidden gates, and dampers, based on the product's structural characteristics and appearance requirements. This runner design effectively balances mold temperature, improving mold precision and productivity.

3. Mould accessories

KRMOLD uses conventional wear-resistant parts like guide pins, guide bushings, and lifters to guarantee the lifespan of the plastic injection mold for washing machine. These top-notch components not only improve washing machine injection mould security but also guarantee long-term, consistent manufacturing efficiency.

4. Plastic washing machine injection mold handling

KRMOLD uses quenching and heat treatment processes to increase mold hardness, followed by nitriding, achieving a surface hardness exceeding HV850. This high surface hardness and wear resistance significantly extend the washing machine injection mould’ lifespan.

3/ Tips for Plastic Washing Injection Machine Mold Maintenance

Plastic washing machine injection mould maintenance is crucial to extending its lifespan. KRMOLD recommends three key aspects of plastic washing machine injection mold maintenance:

1. Daily maintenance for plastic washing machine injection mould

Daily upkeep comprises lubricating several moving components, including ejection pins, guide pins, guide bushings; keeping a pristine mold surface; and draining water routinely. These measures guarantee plastic washing machine injection mould stability during production and help to significantly lower failure rates.

2. Regular maintenance for washing machine injection mold

Routine maintenance comprises cleaning exhaust slots, adding exhaust gas, and fixing worn or damaged parts. Early detection of any issues through frequent inspection and maintenance can help to prevent unanticipated production interruption.

3. Appearance maintenance for plastic washing machine injection mould

Maintaining the washing machine injection mold's appearance is equally important. Paint regularly to prevent rust. Apply anti-rust oil to the plastic washing machine injection mould during storage. Ensure the fixed and movable plastic injection molds for washing machine are tightly closed to prevent dust from entering the mold cavity.

4/ KRMOLD Plastic Washing Machine Injection Mold After-Sales Service

-Timely Response: KRMOLD responds to customer inquiries and questions within 1 to 10 hours.

-Complete Quality Control: KRMOLD implement a strict quality control system at every stage of production to ensure plastic washing machine injection mould quality.

-Competitive Pricing: KRMOLD provides high-quality plastic injection molds for washing machine while maintaining reasonable prices.

-Advanced Project Tracking System: KRMOLD ensure timely mold delivery and enhance customer satisfaction.

-Extensive Export Experience: KRMOLD has accumulated extensive experience in exporting plastic washing machine injection mould to overseas markets and are able to meet international standards.

5/ KRMOLD Plastic Washing Machine Injection Mold Rigorous Manufacturing Process

The manufacturing process for KRMOLD plastic washing machine injection mould is rigorous and includes the following steps:

1. Customer inquiry

Before plastic injection mold manufacturing, KRMOLD will fully communicate with customers to ensure that the price and technical details provided meet their requirements.

2. Plastic washing machine injection mould design

During the manufacturing process, designers are responsible for washing machine injection mold design, considering how the washing machine injection mould will be used by the customer and designing related components to enhance washing machine injection mold manufacturing accuracy and longevity.

3. Plastic washing machine injection mould component processing

Machine operators must demonstrate a high level of responsibility to ensure that mold components are machined to the required accuracy as specified in the drawings. Strict machining processes and dimensional control are key to successful plastic washing machine injection mould manufacturing.

4. Dimensional control for plastic washing machine injection mold

During the manufacturing process, cavities, cores, and other mold components require strict dimensional control. KRMOLD CAM team ensures that all dimensions match the drawings, guaranteeing mold accuracy.

5. Mould assembly

Staff in the injection mold assembly workshop and mass production simulation workshop work together to ensure successful washing machine injection mould manufacturing and deliver plastic injection molds for washing machine that meet KRMOLD standards.

6/ Why Choose KRMOLD Plastic Washing Machine Injection Molds?

Choosing KRMOLD as your washing machine injection mould manufacturer offers the following advantages:

-High-quality products: KRMOLD is committed to providing high-quality plastic injection molds for washing machine, ensuring product stability and durability.

-On-time delivery: KRMOLD strictly adhere to delivery schedules to ensure our customers' production plans are not impacted.

-Competitive Pricing: KRMOLD offers reasonable prices while ensuring quality, ensuring customers receive the best value for money.

-Excellent After-Sales Service: KRMOLD provide comprehensive after-sales support to ensure any issues encountered are promptly resolved.

-Professional Communication: KRMOLD maintain excellent communication with customers to understand and meet their specific needs.

-Complete Injection Molding Lines: KRMOLD provide a complete solution from washing machine injection mould to injection molding machines, streamlining the customers procurement process.

-Mold Flow Analysis Software: KRMOLD use advanced mold flow analysis software to optimize washing machine injection mold design and improve production efficiency.