KINGREAL UNIVERSAL IND., LTD

Phone

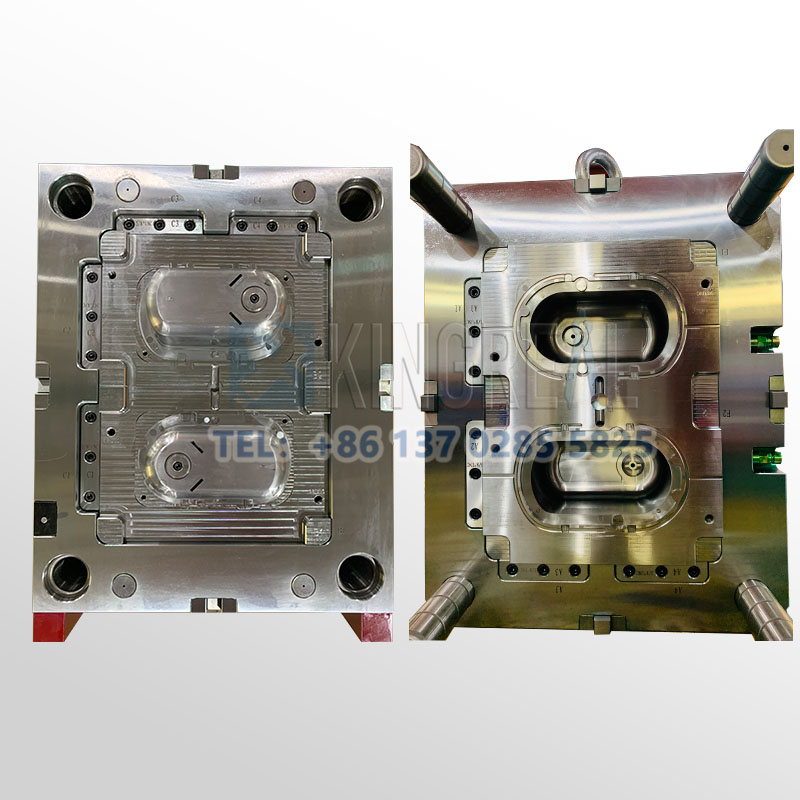

+86-13702855825Multi cavity injection molding refers to the number of cavities in the mold to accommodate products. There are many cavities in the high temperature multi cavity injection molds, and multiple products can be produced at the same time in each multi cavity injection molding. High temperature multi cavity injection molds are suitable for producing a large number of products, such as daily necessities, toys and so on. High precision multi cavity electronics injection mold can produce multiple products at the same time, with high production efficiency and short injection cycle, which can meet the needs of mass production.

High precision multi cavity electronics injection mold is used to create two or more copies of the same part in one die tool using multiple dies of the part in each cycle. In multi cavity injection molding, the high temperature multi cavity injection molds are designed with runner and gate, allowing molten plastic materials to flow to each cavity with similar filling, pressure holding, holding and cooling time.

| 1 | Advantages of High Temperature Multi Cavity Injection Molds |

| 2 | Application of Multi Cavity Injection Molding |

| 3 | Factors to be Considered in the Design of Multi-cavity Injection Mold |

Advantages of High Temperature Multi Cavity Injection Molds

1. high efficiency.

Because multiple products can be produced by one injection, the production efficiency of high precision multi cavity electronics injection mold with one mold is much higher than that of single cavity mold. This is undoubtedly a huge advantage for mass production enterprises.

The traditional single-cavity mold can only produce one product in each injection process, while the high precision multi cavity electronics injection mold can produce multiple products in one injection. For those enterprises facing large-scale order demand, this feature is undoubtedly very attractive.

This high efficiency is not only reflected in the substantial increase in output, but also shortens the delivery cycle of products. Enterprises can bring products to the market faster, seize market opportunities, meet the needs of consumers and enhance their competitiveness in the market.

2. Reduce costs.

The simultaneous production of multiple products means that the output per unit time increases, thus reducing the production cost of a single product. In addition, according to the principle of cost accounting, the fixed costs (such as equipment depreciation, mold manufacturing costs, workshop rental costs, etc.) and variable costs (such as raw material costs, energy consumption costs, etc.) shared by unit products will be reduced accordingly, further reducing production costs.

In terms of variable cost, high precision multi cavity electronics injection molding is helpful to reduce waste and energy consumption. In the process of multi cavity injection molding, some wastes, such as gate waste and flash waste, will inevitably be produced during the injection of plastic from the nozzle of injection molding machine into the mold cavity. The amount of waste produced by each injection of single-cavity mold is not much different from that of high temperature multi cavity injection molds, but the amount of waste produced per unit product is relatively reduced because of the large number of products injected by high temperature multi cavity injection molds at one time.

3.Good consistency.

Because all products are produced in the same mold and under exactly the same injection conditions, including the temperature, pressure, injection speed and cooling time of plastics, the quality and size of the products produced are extremely consistent.

For some industries that require high product quality and dimensional accuracy, such as automobile parts manufacturing and medical device manufacturing, product consistency is particularly important. This high degree of product consistency has established a good brand image for the enterprise, won the trust of customers, and is conducive to establishing long-term and stable cooperative relations in the market and promoting the sustainable development of the enterprise.

Application of Multi Cavity Injection Molding

Factors to be Considered in the Design of Multi-cavity Injection Mold

I. Number and arrangement of cavities

The number of cavities is usually given by the manufacturer, taking into account the production batch of products and the model of high precision multi cavity electronics injection molding machine. For example, "one out of four" means the design of one mold and four cavities.

The arrangement of cavities should take into account the design of mold parts, core-pulling structure and ejection mode.

2. Mold structure

If plastic parts require high appearance quality, average dimensional accuracy and high assembly accuracy, it may be necessary to adopt the design of multi-cavity and multi-parting surface.

The number and position of parting surfaces should be determined according to the structure of plastic parts, for example, the motor insulation rubber frame may need three parting surfaces.

3. Design of runner system

In the high precision multi cavity electronics injection mold, the runner system is usually designed as an "H" structure to realize the flow and filling balance of molten resin.

It is necessary to pay attention to the problems that may exist in the "H" runner system, such as flow shear heat generation and uneven melt temperature distribution, and it may be necessary to improve the high precision multi cavity electronics injection mold and process.

4. Gate design

The gate should be set in the place where the product is most easily removed, and the appearance should not be affected as much as possible.

The location of the gate should ensure that the distance from all parts of the cavity is as consistent as possible to provide equal flow length.

The design of the gate should be conducive to the gas discharge in the cavity, so as to avoid the direct impact of molten plastic on weak cores, inserts, rows, etc., and prevent the deformation of products.