KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825IMD injection molding is also called thermoplastic injection in-mold decoration. In essence, this is an advanced manufacturing technology that deeply integrates decorative film into the injection molding process. In the specific operation process, the decorative film is precisely embedded into the surface of plastic products in the IMD injection molding process. This operation is not a simple superposition, but through the close combination of molten plastic and film during injection molding, the integration of the two is realized.

As a result, the product not only presents a high-quality appearance effect, but also has excellent wear resistance, scratch resistance and chemical corrosion resistance. It can be said that thermoplastic injection in-mold decoration is the perfect integration of traditional injection molding technology and modern decoration technology, which opens up a new path for improving the appearance and performance of products.

| 1 | Process Flow of IMD Injection Molding |

| 2 | Characteristics of IMD Injection Molding |

| 3 | Application of IMD Injection Molding |

1.Process Flow of IMD Injection Molding

Preparation of decorative film: usually, the printed film is shaped.

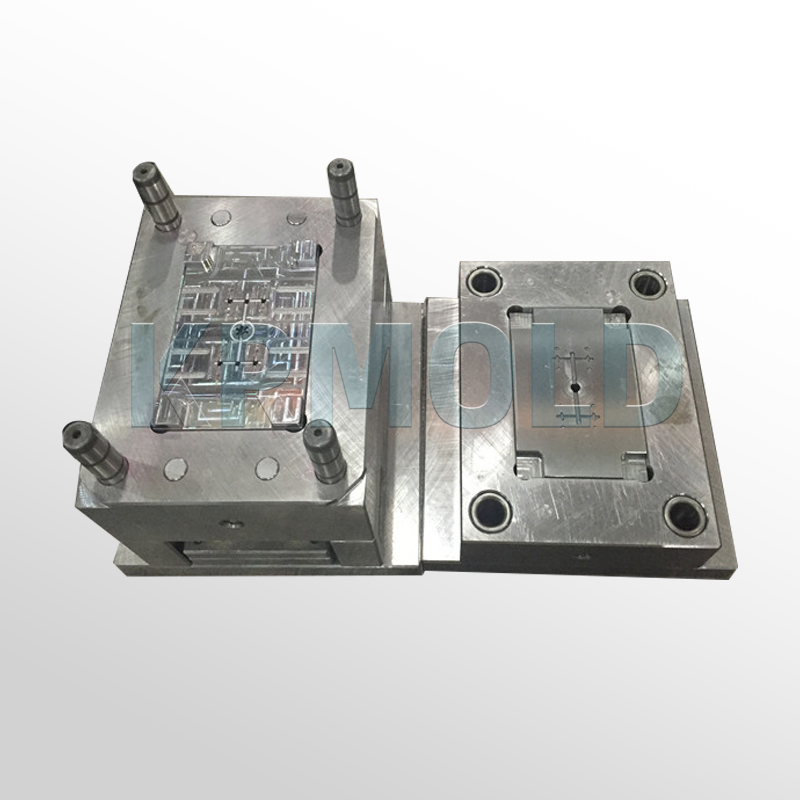

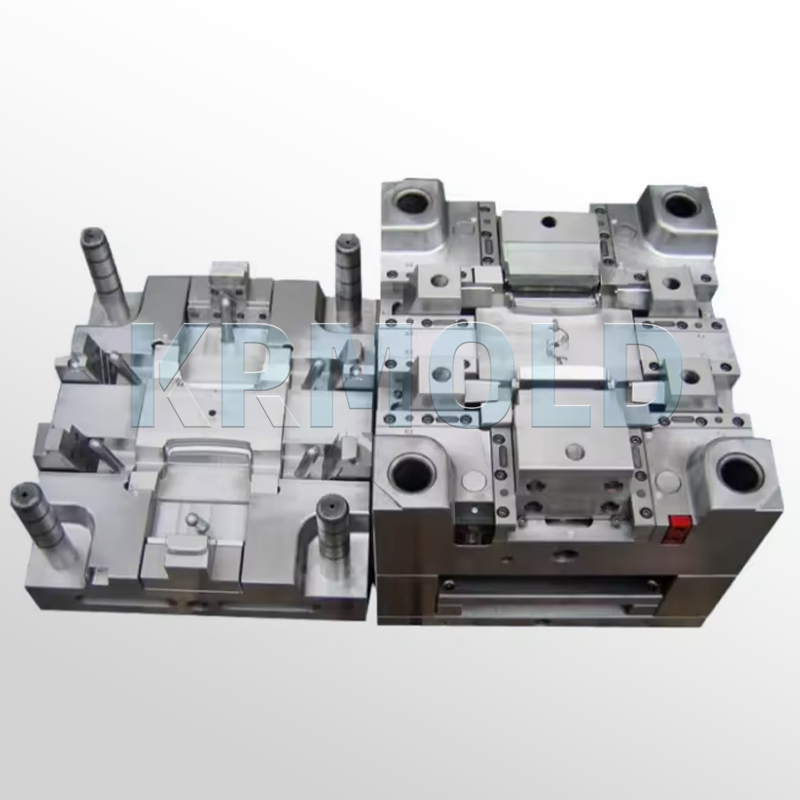

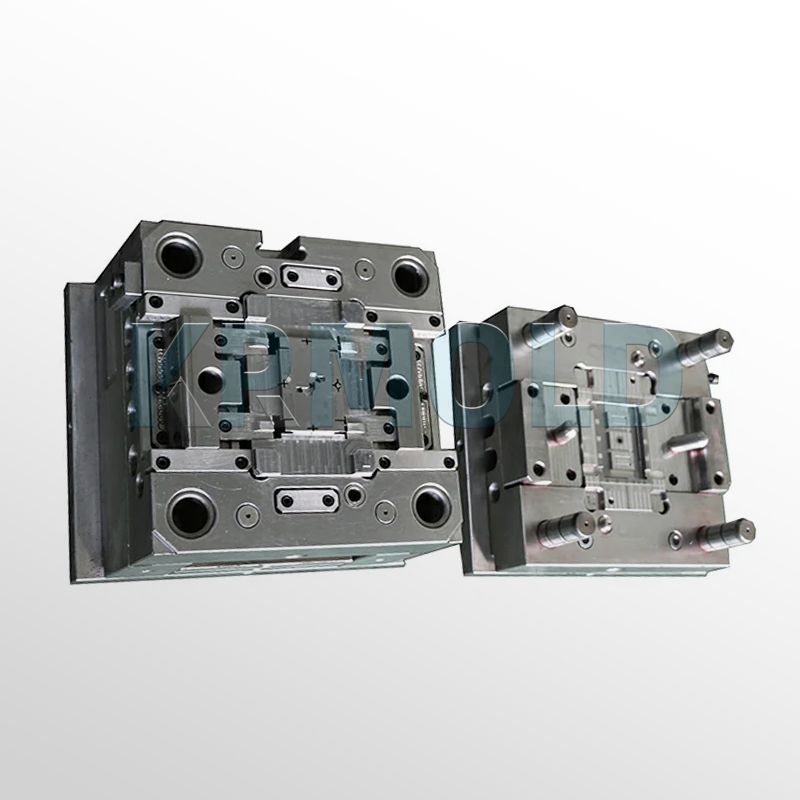

Film placement: the formed film is embedded in the IMD injection mold cavity.

Mold closing and injection molding: after the IMD injection mold is closed, molten plastic is injected into the mold by an injection molding machine, and the plastic is combined with the ink layer on the back of the film.

Cooling and solidification: the molten plastic is cooled and solidified to form a product with the same shape as the mold.

Take out the product: open the mold and take out the molded plastic product with decorative effect.

2.Characteristics of IMD Injection Molding

(1)High precision.

In the process of IMD injection molding, the decorative film embedded in the mold and the precise control of the injection process have jointly created the excellent performance of the product in terms of dimensional accuracy and shape accuracy. Take the automobile dashboard as an example, its complex shape and high-precision assembly requirements are harsh.

Through the IMD injection molding, the design requirements of the instrument panel can be accurately realized, and the coordination between various components can be ensured to be close and seamless, and the error can be controlled within a very small range. No matter the scale on the dashboard, the installation position of the pointer, or the layout of various function buttons, they can be perfectly presented through high-precision molds and precise injection molding processes, providing drivers with clear and accurate information display, and at the same time improving the quality and reliability of the entire dashboard.

(2)High quality.

The high quality of IMD injection molding products is not only reflected in the exquisite appearance, but also in its excellent physical properties. The surface of the product not only has a beautiful and generous decorative effect, but also meets the aesthetic needs of consumers for the appearance of the product, and also has excellent characteristics such as wear resistance, scratch resistance and chemical corrosion resistance.

These characteristics enable the product to maintain good appearance and performance in the long-term use process, effectively reduce the maintenance and replacement costs caused by surface damage, and greatly improve the overall quality of the product and user satisfaction.

(3)High complexity.

IMD injection molding process is a complex process involving multiple links and technologies. It covers many professional fields, such as printing, film forming, injection molding, etc., and all links need close cooperation and collaborative work, which puts forward extremely high requirements for the precision, stability and accuracy of process control of equipment. From the design and manufacture of decorative film, to the precise placement of the film in the injection mold cavity, to the precise adjustment of parameters such as temperature, pressure and speed in the injection process, every step needs to be strictly controlled, and any slight deviation in any link may have a serious impact on the quality of the final product.

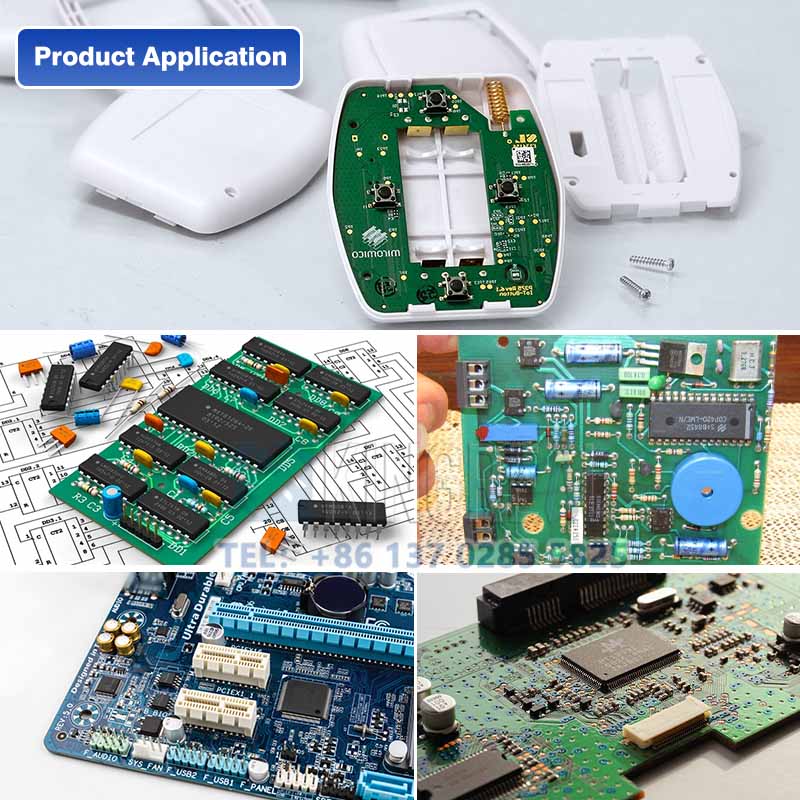

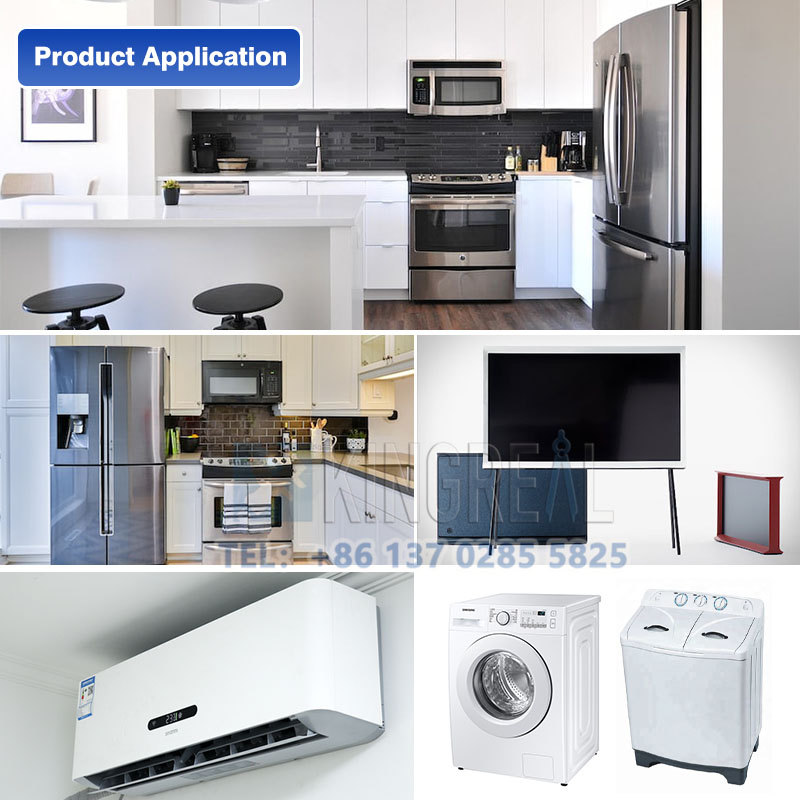

3.Application of IMD Injection Molding

In automobile interior, the application of thermoplastic injection in-mold decoration is extremely extensive and in-depth. As an important display and control area in the car, the dashboard of the car has very strict requirements on the aesthetics of appearance, convenience of operation and durability. Through thermoplastic injection in-mold decoration, the dashboard surface can present high-quality textures and colors, which not only greatly improves the overall texture of the interior, creates a luxurious and comfortable driving atmosphere, but also significantly enhances the scratch and wear resistance of the surface. The instrument panel adopting thermoplastic injection in-mold decoration can effectively resist these abrasion, ensure that the instrument panel always maintains good appearance and function in the long-term use process, with clear scale and sensitive keys, and provide accurate and reliable information and convenient operation experience for drivers

In the household appliances industry, the IMD injection mold also plays an important role. By using IMD injection mold, the shell of household appliances can realize diversified and personalized appearance design, and meet the pursuit of different consumers for home style and aesthetic needs. For example, by printing different patterns and colors, the shell of household appliances can present a variety of effects such as imitation metal texture, wood grain texture and stone grain texture, adding more fashion elements and artistic atmosphere to the home environment. Taking the refrigerator as an example, the decorative film on the surface of the refrigerator not only has beautiful and elegant patterns, but also has good fingerprint resistance and easy cleaning performance after the shell is injected into the film、

Thermoplastic injection in-mold decoration enables the mobile phone case to realize colorful and creative design, from dazzling gradient color to delicate and delicate texture pattern, which satisfies the pursuit of individuality and fashion of different consumers. At the same time, the wear and scratch resistance of the surface of the mobile phone shell effectively protects the appearance integrity of the mobile phone in daily use and reduces the impact of scratches and wear on the aesthetics of the mobile phone