KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Draft is a critical design factor in the process of packaging injection molding. Although your part may be molded correctly in the cosmetic container injection molds, problems may occur during the demolding process, which may cause unnecessary defects in the molded part. The design of the draft will help avoid many of these unnecessary problems. In this article, KRMOLD will take a deep dive into draft in injection molding in cosmetic packaging, including its definition, role, influencing factors, and best practices.

| 1 | Definition of Draft |

| 2 | The Role of Draft in Injection Molding in Cosmetic Packaging |

| 3 | Factors Affecting the Size of Draft |

| 4 | Best Practices for Optimizing Drafts |

1.Definition of Draft

Draft refers to the slight taper or inclination of the vertical surface of the molded part, usually toward the vertical axis of the cosmetic container injection molds or the parting line. Draft is expressed in degrees, and in many cases, the corresponding dimensions are also described in millimeters or inches. Reasonable draft design is a key factor in ensuring that plastic parts can be smoothly ejected from the cosmetic container injection molds.

By adding draft to the injection molded part, the friction during demolding can be significantly reduced, making the part easier to remove from the mold. On the contrary, parts without draft angle or straight walls may be damaged by friction during demolding.

2.The Role of Draft in Injection Molding in Cosmetic Packaging

(1) Facilitate part removal

Part ejection is a critical step in the injection molding in cosmetic packaging. Plastic parts come into contact with the cosmetic container injection molds walls during manufacturing, so the friction generated when ejecting the part can cause serious damage. A properly designed draft can minimize or eliminate friction, which helps facilitate easy demolding.

When the draft of the part is designed properly, the ejector pin can smoothly push the part out of the cosmetic container injection molds without causing defects in the surface finish. In contrast, abandoning the draft will cause the part to rub against the side of the mold during demolding, resulting in scratches and other surface defects.

(2) Prevent damage caused by part ejection

Insufficient draft can cause serious problems. During the ejection process, the part may drag against the side of the cosmetic container injection molds, which not only causes scratches, but can also cause damage to the cosmetic container injection molds itself. If the finished part is stuck in the mold, it can cause unexpected delays and additional costs. Therefore, a properly designed draft angle is an effective way to solve such problems.

(3) Reduce Deep Draw

The draw line or parting line is the point where the two cosmetic container injection molds halves separate and release the finished product. The depth of the draw is a key parameter that affects how easily the part can be demolded. A shorter draw depth minimizes the risk of the part getting stuck in the mold, while a longer draw increases this risk. By increasing the draft, the effect of deep draw can be reduced, which helps to easily demold the part.

(4) Reduce Warpage

Warpage is a common defect in injection molding in cosmetic packaging, which usually causes the part to twist or deform after injection molding in cosmetic packaging. Omitting the draft angle can cause a vacuum to form in the mold cavity during the ejection process. This vacuum has the undesirable effect of causing the part to fold or warp itself. A proper draft angle design can eliminate this problem because it allows air to occupy the cavity in the cosmetic container injection molds, preventing the formation of a vacuum.

3.Factors Affecting the Size of Draft

Several factors affect the size of the ideal draft in injection molding in cosmetic packaging. Here are some key factors:

(1) Material properties

The material selected has a direct impact on the size of the draft. For example, soft plastics such as nylon generally require less draft than hard plastics such as polycarbonate. This is because softer materials will show higher flexibility when ejected, which is easy to form a better fit during the demolding process.

(2) Shrinkage

The shrinkage of the material is also an important factor affecting the draft. When using materials with larger shrinkage, a larger draft is generally required. High shrinkage means that the part is more likely to stick to the sides of the cosmetic container injection molds during the cooling phase, so choosing a larger draft can help support the smooth ejection of the plastic part.

(3) Friction coefficient

Materials with lower coefficients of friction, such as nylon and polyoxymethylene, generally require a smaller draft. Plastics with higher coefficients of friction, on the other hand, require a larger draft to ensure successful demolding. This is because a higher coefficient of friction will cause greater friction during demolding, so this resistance needs to be overcome by increasing the draft.

(4) Wall thickness

The wall thickness of the injection molded part will also affect the design of the draft. Thicker walls wrap more tightly around the cosmetic container injection molds, so a larger draft is required in the product design to ensure that the part can be smoothly demolded.

(5) Geometric Complexity

The geometry of the part is an important consideration when determining the size of the draft. Complex parts with features such as undercuts, overhangs, and deep cavities generally require steeper drafts to ensure smooth demolding from the cosmetic container injection molds.

(6) Mold Design

The surface finish of the mold directly affects the effectiveness of the draft. If the cosmetic container injection molds side is smooth, the friction during ejection will be reduced, allowing for a softer draft. In contrast, rough surfaces require a larger draft to achieve the best results.

4.Best Practices for Optimizing Drafts

It is critical to design a proper draft to ensure smooth demolding of the part during the injection molding in cosmetic packaging. Here are some best practices for optimizing drafts:

(1) Perform a detailed material analysis

When selecting a material, consider its shrinkage, coefficient of friction, and flexibility. These factors will directly affect the final draft design.

(2) Accurately calculate the draft

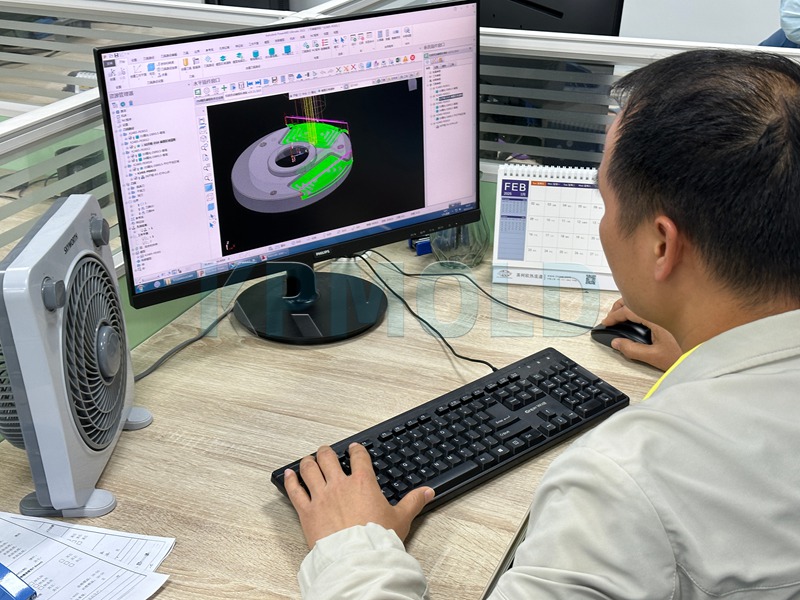

According to the geometry and wall thickness of the part, use CAD software to accurately calculate the draft. Ensure that the design meets the actual production needs while leaving appropriate margins to cope with possible errors.

(3) Optimize the mold design

By optimizing the mold design, ensure that the mold surface is smooth to reduce friction. This not only helps with drafting, but also improves the surface finish of the finished product.

(4) Conduct mold trials and feedback

Perform mold trials before formal production to verify the effectiveness of the draft angle. The feedback obtained through mold trials can help designers further optimize the draft angle and ensure the quality of the final product.

(5) Communicate with manufacturers

Maintain good communication with mold manufacturers and injection molding in cosmetic packaging machine operators to ensure that they have a clear understanding of the design of the draft. This helps to find and solve problems in time during the production process.