KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825ABS is a terpolymer of acrylonitrile (A), butadiene (B) and styrene (S). The relative contents of the three monomers can be changed at will to make various resins, which are often used in ABS plastic injection molding.

ABS plays an important role in electronics industry, machinery industry, transportation, building materials, toy manufacturing and other industries because of its large mechanical strength and good comprehensive performance, especially in the slightly larger box structure and stress parts, the decorations that need electroplating cannot be separated from this plastic.

| 1 | Process of ABS Plastic Injection Molding |

| 2 | Key Points of ABS Plastic Injection Molding |

1.Process of ABS Plastic Injection Molding

1.1 ABS plastic drying

ABS plastic is hygroscopic and sensitive to moisture. If it is fully dried and preheated before processing, it can not only remove the pyrotechnic bubble band and silver wire on the surface of the product, but also help to plasticize the plastic and reduce the color spots and ripples on the surface of the product. The moisture content of ABS raw materials is controlled below 0.13%.

1.2 Injection temperature

The relationship between ABS plastic temperature and melt viscosity is different from other amorphous plastics. When the temperature rises in the melting process, its melting will actually decrease slightly, but when it reaches the plasticizing temperature (the temperature range suitable for processing, for example, 220~250℃), if the temperature continues to rise at will, the thermal decomposition of ABS with low heat resistance will increase the melting viscosity and reach ABS plastic injection molding.

Therefore, the injection temperature of ABS is higher than that of plastics such as polystyrene, but it cannot have a slow temperature rise range like the latter. In some injection molding machines with poor temperature control, when ABS products are produced to a certain amount, yellow or brown caulking particles are often embedded in the products, so it is difficult to remove emissions by injecting new materials into the sky.

1.3 Injection pressure

Because the viscosity of ABS melt is higher than that of polystyrene and modified polystyrene, higher injection pressure is used for injection. Of course, not all ABS products have high pressure, and lower injection pressure can be used for products with small volume, simple structure and large thickness.

In the process of ABS plastic injection molding, the pressure in the cavity at the moment of gate closure often determines the surface quality of the product and the degree of silver filiform defects. If the pressure is too small, the plastic will shrink greatly, and the chances of leaving the cavity surface are great, and the product surface will be atomized. When the pressure is too high, the friction between the plastic and the cavity surface is strong, and the ABS appliance component injection molds are easy to stick together.

1.4 Injection speed

It is better to use moderate injection speed for ABS material. If the injection speed is too fast, the plastic will be easily burnt, and the gas will be decomposed and separated, resulting in defects such as weld marks, poor gloss and red plastic near the gate. However, in the production of thin-walled and complex products, it is necessary to ensure a sufficiently high injection speed. Otherwise, it will be difficult to satisfy.

1.5 Mold temperature

The forming temperature of ABS is relatively high, and the ABS appliance component injection molds temperature is also relatively high. Generally, the mold temperature is adjusted to 75~85℃, but when producing products with large projection area, it is required that the fixed mold temperature is 70~80℃ and the moving mold temperature is 50~60℃. When injecting thin-walled plastic parts with large and complex shapes, special consideration should be given to heating the ABS appliance component injection molds. In order to shorten the production cycle and keep the mold temperature relatively stable, after taking out the product, cold water bath, hot water bath and other mechanical shaping methods can be used to compensate for the time of cold setting the ABS appliance component injection molds in the cavity.

1.6 Material management

When the general injection molding machine injects ABS plastic, its single injection amount only reaches 75% of the standard injection amount. The injection amount should be 50% of the calibrated injection amount, so as to improve the stability of product quality and size, and make the surface luster and color tone uniform.

2.Key Points of ABS Plastic Injection Molding

2.1 mold design

The wall thickness of products should be uniform, and the wall thickness difference of ABS products should be controlled within 25% to prevent local stress concentration due to excessive wall thickness difference. At the root of weak strength column, fillet or stiffener must be added to prevent the column from breaking.

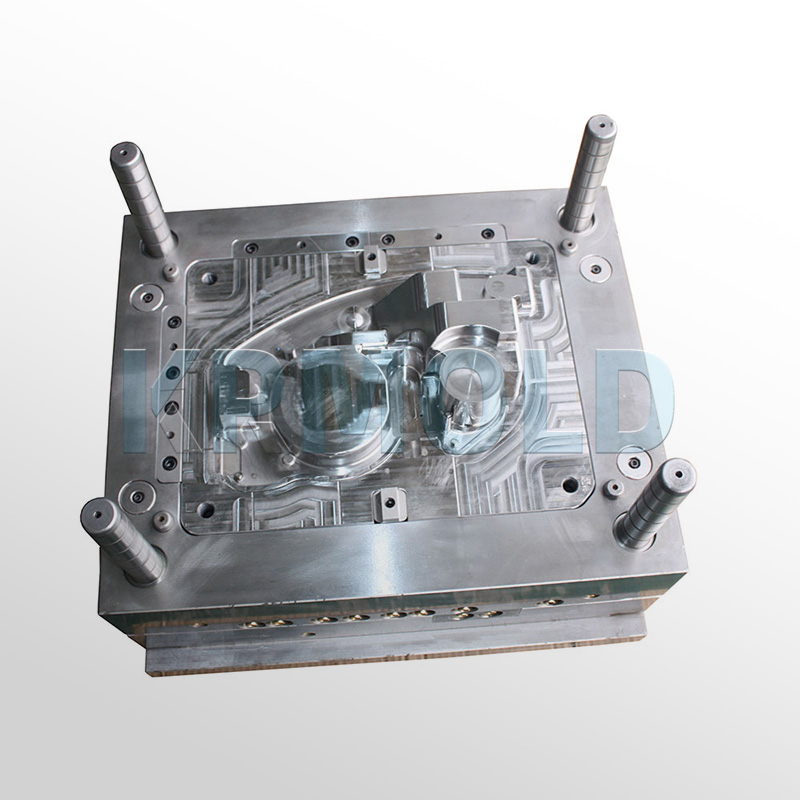

The design of ABS appliance component injection molds cooling channel should ensure cooling uniformity and avoid internal stress caused by uneven cooling and uneven shrinkage.

2.2 material drying

Heat-resistant ABS resin usually absorbs moisture in the air during storage and transportation. Water absorption varies with air humidity, usually between 0.2 and 0.4%. Therefore, it is necessary to fully dry the material so that the water content of the material is below 0.05%, preferably below 0.02%. Otherwise, surface defects such as splash and silver wire may occur. The drying temperature of heat-resistant ABS resin is higher than that of conventional ABS, usually 80-95℃, and the drying time is 3-4 hours.

2.3 forming temperature

Molding temperature is one of the most noteworthy parameters in the processing of heat-resistant ABS. Based on ensuring full plasticization of heat-resistant ABS, try to use the temperature range above the middle value of ABS plastic injection molding temperature recommended by the supplier. With the increase of ABS plastic injection molding temperature, the viscosity of heat-resistant ABS is obviously reduced, the fluidity of resin is increased and the flowing distance is extended, which ensures that the material has sufficient filling ability.

2.4 holding pressure and time

For heat-resistant ABS, whether the setting of holding pressure and time is reasonable directly affects the internal stress of the product. The increase of holding pressure can reduce the molecular gap, reduce the moving range of the segment, reduce the melt volume, increase the density, increase the intermolecular force, and improve the shrinkage and internal quality of the product. However, due to the increase of internal stress, the holding pressure should be reduced as much as possible to ensure the appearance quality of the product.

The setting of pressure holding time is based on the time when the gate solidifies with cooling and the screw pushes forward again without exerting pressure on the molded product. When the holding time is too long, the material filling is easy to be excessive, the molecular gap becomes smaller and the internal stress becomes larger; If the pressure holding time is too short, the product is easy to shrink and the size is unstable. The best holding time is the shortest time when the weight of the product does not change.

2.5 mold temperature

In order to control the ABS appliance component injection molds temperature when ABS plastic injection molding heat-resistant ABS, a mold temperature machine is used. The recommended die temperature is 60-80℃. The mold temperature is high, the flow is good, the weld line strength is high, and the internal stress of the product is small, but the ABS plastic injection molding cycle is moderately prolonged.

If the ABS appliance component injection molds temperature is lower than the recommended temperature, the internal stress of the product will be too high, and the performance of the product will decrease, which may lead to brittle cracking of the product, cracking of threaded holes, cracking of painting, etc.