KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825The cost of IMD Injection Molds is very important in manufacturing. It varies based on factors such as mold type, size, complexity, and production volume—from $100 for a 3D printed mold to over $100,000 for a large steel mold. Understanding these IMD Injection Molds and IMD Injection Molding costs informs strategic manufacturing decisions. |  |

| 1 | Explore Factors Affecting IMD Injection Molds Costs |

| 2 | IMD Injection Molding Machine |

| 3 | Impact of Mold Material on Cost |

| 4 | Significance of Labor and Maintenance Expenses in IMD Injection Molding |

1.Explore Factors Affecting IMD Injection Molds Costs

Far from being fixed, the cost of IMD Injection Molds is comprised of a range of influencing factors. Unpacking these factors helps understand the complexity of pricing in this important area of manufacturing.

1

Type, Size, and Complexity of IMD Injection Molds

The mold type, whether single-cavity or plastic multi-cavity injection molds, as well as their size and complexity, significantly impact overall costs. Complex designs or features can add expense, while multi-cavity injection molds can be more cost-effective.

2

Production Volume

The desired production volume is key in determining cost. For lower production volumes, budget-friendly 3D printed molds can be chosen for around $100, while large multi-cavity injection molds can cost over $100,000 for high-volume production.

3

Equipment, Design, Materials, Labor and Maintenance

The convergence of equipment, design complexity, material selection, skilled labor and maintenance requirements all interact to determine the final cost.

4

Achieve cost effectiveness through mass production

As production volume increases, the cost per part decreases, making IMD injection molding a cost-effective option for mass production.

2.IMD Injection Molding Machine

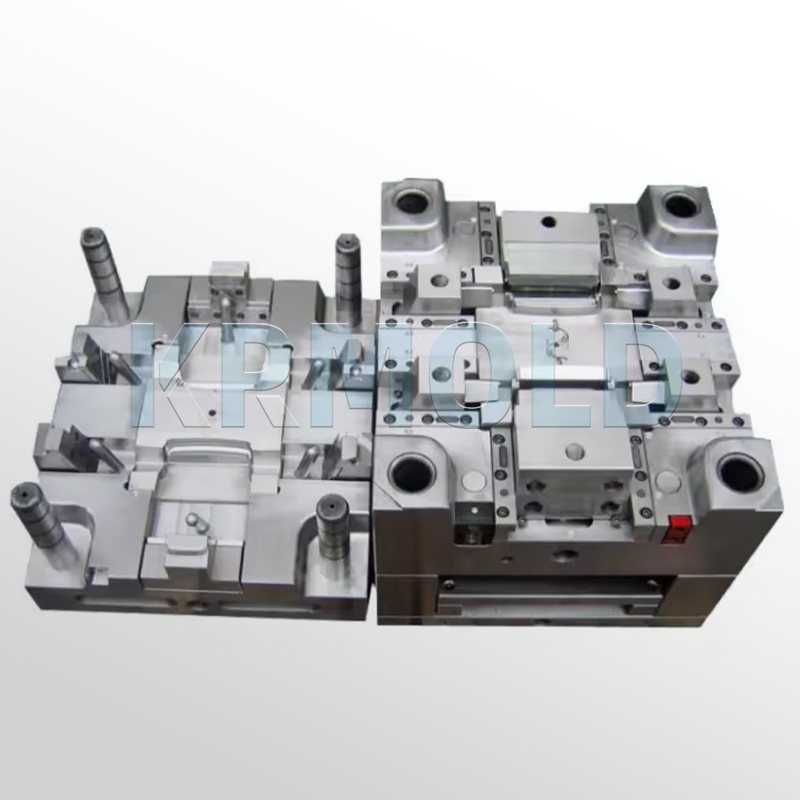

IMD Injection Molding Cost The price of a machine is closely related to its size, type, complexity and production volume. A commonly used general-purpose machine with a capacity between 80T-200T may cost between $18,000 and $60,000. On the other hand, automated machines used for medium-volume production of smaller parts may be cheaper, costing less than $50,000. In contrast, large industrial machines designed for high-volume, multi-cavity injection molds may cost more, exceeding $200,000.

1

One essential costing part for IMD Injection molds

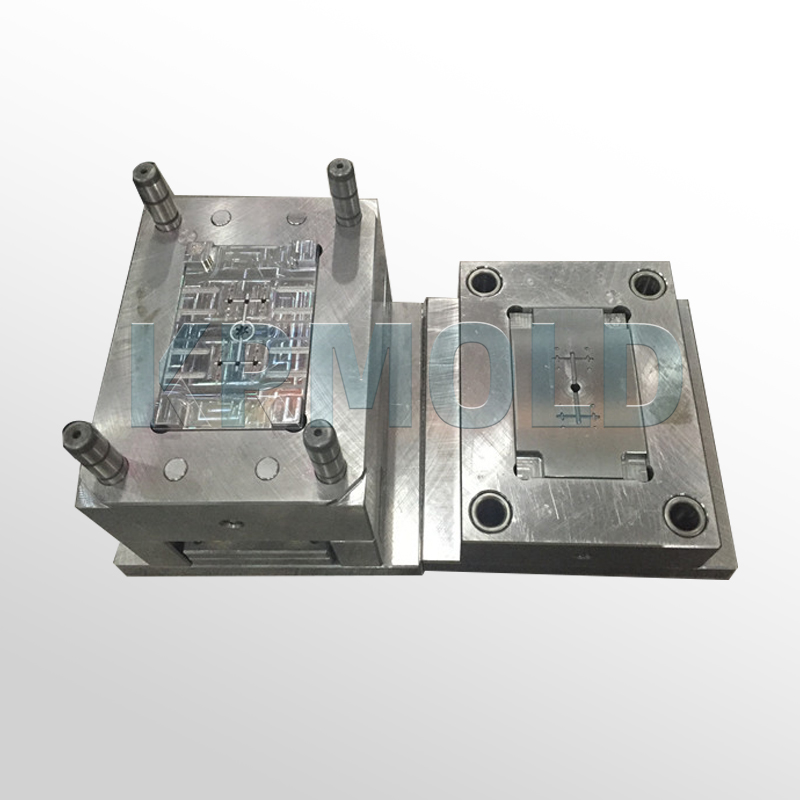

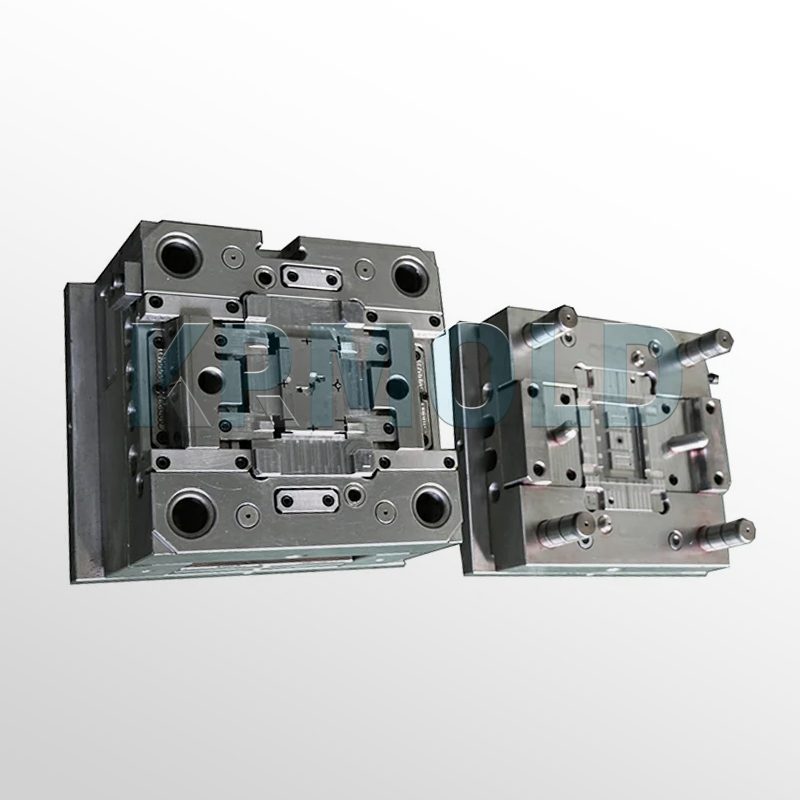

A significant part of the entire cost comes from IMD injection molds, which vary greatly in price. Mold costs can vary from a few thousand dollars to $50,000 depending on elements like the number of cavities and the complexity of the form; this demonstrates the complexity and degree of customization needed to create IMD Injection. Molds to exactly satisfy specific manufacturing needs.

2

Costs related to non-material

Other costs in addition to raw materials—machine rates, rental, power, and labor costs—are determined using cycle time and the number of units made per hour.

3

Cost impact of mold design

The cost of IMD injection mold is closely related to its design, and there are several key factors that affect the overall expense.

4

Production volume and complexity

Mold costs vary depending on the required production volume and part complexity. The costs associated with 3D printing molds range widely, from $100 for a simple mold suitable for low-volume production to $100,000 for a complex mold suitable for high-volume production, and reduce the IMD injection molding cost.

5

Material and process of IMD Injection Molding

The choice of mold material (whether aluminum or steel) and the process used to make the mold are key factors that affect cost determination. Rapid Prototype, pilot run or full-scale production IMD Injection Molds all have different price points.

6

Size and Cavity of IMD Injection Molds

The complexity, material and precision of the IMD Injection Molds (prototype, pilot run or full-scale production) affect the cost. The cost of a mold varies greatly depending on its complexity and expected production volume.

3.Impact of Mold Material on Cost

IMD injection molding material's choice has a great influence on its total price, and several variables combine to influence the price. For producers looking for affordable solutions, a closer examination of the connection between mold material and cost can provide insightful ideas.

●Volume of production and sophistication in design The complexity of component design and the scale of production directly influence the choice of mold material, therefore influencing the overall cost. Starting at just $100, rapid production of tiny batches' 3D printed molds provides an inexpensive option. On the other hand, creating sophisticated molds to satisfy the demands of large-volume manufacturing can raise expenses dramatically, even reaching $100,000. |  |

●Thermoplastic's Popularity IMD injection molding mostly uses several thermoplastics including TPU, PP, PC, PS, PE, and ABS. Every thermoplastic offers particular uses, availability, and pricing points. Depending on the particular material qualities, thermoplastics often employed in this method run between $1 and $5 per kilogram. |  |

●Additional Cost Considerations In addition to the material itself, various other factors can affect the total mold cost. Factors such as mold design complexity, processing complexity, surface treatment requirements, and potential additional processing can all affect the final financial expenditure. |  |

4.Significance of Labor and Maintenance Expenses in IMD Injection Molding

The total cost ofIMD injection molds depends mostly on the cost effect of maintenance and labor. Knowing how these elements influence the IMD injection molding services enables one to make wise judgments and maximize budget distribution.

●Labor Costs Expenses related to labor span several phases including mold design, manufacture, and upkeep. Labor expenses might be influenced by the complexity of the mold design, the desired production volume, the mold material, and the chosen production method. With prices as low as $100, simple, low volume 3D printed molds may present a cost-effective alternative. On the other hand, costs for a sophisticated mold made for high-volume production could reach $100,000.

●Cost of upkeep One of the most important components in guaranteeing the ongoing performance and life of a mold is maintenance. Proper storage, maintenance including repairs, and cleaning all help to guarantee the ongoing creation of excellent components. The size of the IMD injection molds, their intricacy, the frequency of use, and the degree of knowledge needed for maintenance all affect maintenance expenditures.

●Maximizing Labor and Upkeep Expenses

• Skilled Workers Efficiency in mold design, manufacture, and maintenance is guaranteed by investments in competent and knowledgeable technicians and engineers. Although competent workers may command more pay, their knowledge lowers the probability of errors and expensive correction, finally proving cost-effective in the long run.

• Preventive Maintenance Regular inspections and quick fixes reduce mold performance and lower downtime by helping to spot and solve possible problems before they develop into worse problems.

• Efficient Storage Good storage practices lengthen the life of the IMD Injection Molds, lower the number of repairs, and protect molds from damage and deterioration during periods of nonuse. |  |

For makers to grasp the several variables impacting IMD Injection Molds' pricing is vital. Design complexity, material selection, output volume, and labor and upkeep costs all have a major influence in determining total expenses. By grasping these main elements, producers may make wise judgments and successfully maximize the costbenefit of IMD injection molds and IMD injection molding costs operations.