KINGREAL UNIVERSAL IND., LTD

Phone

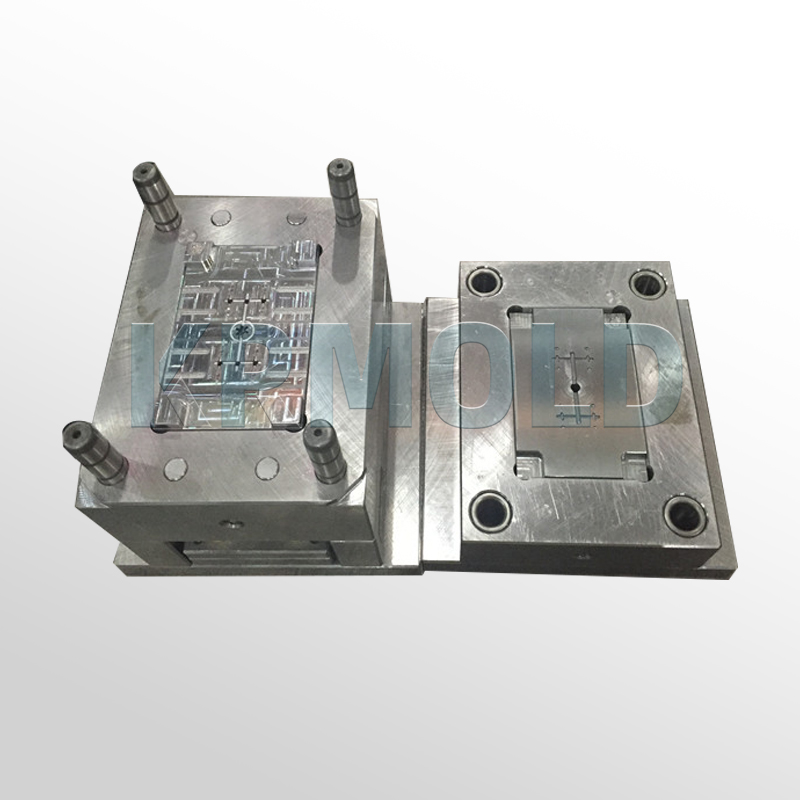

+86-13702855825| IMD injection molding is an important application in modern plastic injection molding technology, which can complete the decoration process in the IMD injection molds. IMD injection molded products have the advantages of high appearance clarity, good three-dimensional sense and surface scratch resistance, so they are widely used in many fields such as automobiles, home appliances, consumer electronics and medical electronics.

In this article, KRMOLD will discuss in detail how the process conditions of IMD injection molding affect the quality and performance of products, focusing on the correlation between IMD injection molding and IMD injection molds. |  |

| 1 | Overview of IMD Injection Molding |

| 2 | Material Selection and Performance |

| 3 | Injection Temperature |

| 4 | IMD Injection Molds Temperature |

| 5 | Injection Time |

| 6 | Advantages of IMD Injection Molding |

1. Overview of IMD Injection Molding

IMD injection molding is a technology that combines decorative film with plastic material in the same molding process. This process not only improves production efficiency, but also reduces costs. By completing the decoration in the IMD injection molds, the subsequent processing steps are reduced, saving manpower and time.

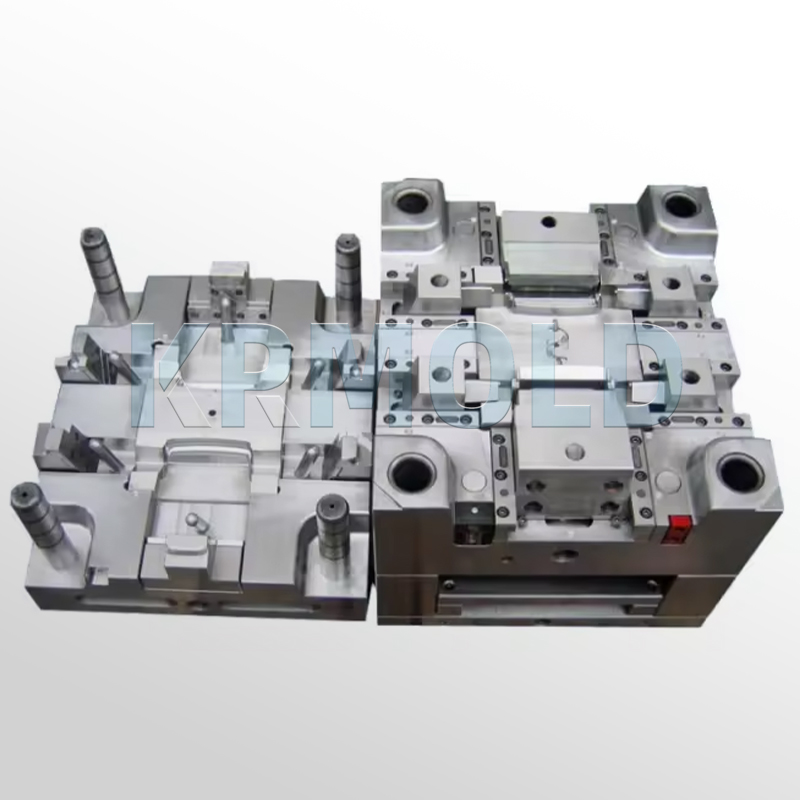

1.1 Application of IMD injection molds

IMD injection molding is particularly suitable for products that require complex patterns and high visual effects, such as mobile phone housings, home appliance control panels and car dashboards. Due to its excellent durability and aesthetics, IMD injection molded products are highly competitive in the market.

2. Material Selection and Performance

Selecting the appropriate plastic material is the first stage in IMD injection molding. The complexity of injection molding is directly dependent on the performance of the plastic material, which can vary greatly between brands and batches of materials. For different material qualities, therefore, the process parameters have to be changed appropriately.

2.1 The influence of plastic materials

The type, melting point, and fluidity of plastics are all important factors affecting IMD injection molding. Generally speaking, higher melting point materials require higher injection temperatures to ensure that the melt can flow smoothly into the IMD injection molds, and the difference in fluidity of different materials will affect the quality of molding.

3. Injection Temperature

Important factor in the IMD injection molding process is injection temperature. Heat conduction causes the melt to lose heat as it enters the cooling cavity; direct temperature changes then influence the viscosity and fluidity of the melt.

3.1 The effect of temperature on viscosity

The viscosity of the melt drops with rising injection temperature, which lowers the necessary filling pressure. The thermal degradation and decomposition temperatures restrict the injection temperature as well, hence a balance must be struck in choosing it to prevent thermal deterioration of the material.

4. IMD Injection Molds Temperature

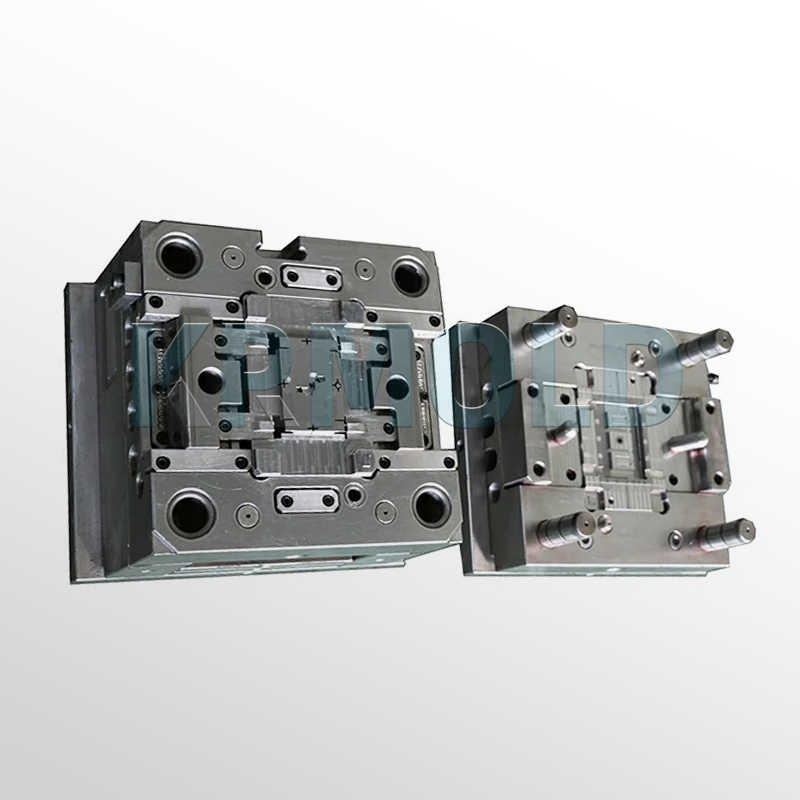

IMD injection molds temperature is also an important factor that cannot be ignored in IMD injection molding. Too low IMD injection molds temperature will cause the melt to dissipate heat too quickly and have poor fluidity, thus affecting the molding quality.

4.1 Relationship between temperature and fluidity

In IMD injection molding, IMD injection molds temperature control is very important. Excessive IMD injection molds temperature might compromise the adhesion of the decorative film, whereas too low mold temperature could result in surface flaws on the molded component. Reasonable management of IMD injection molds temperature therefore holds the secret to guaranteeing the quality of IMD injection molding.

5. Injection Time

The length of injection time also has a significant impact on IMD injection molding. By adjusting the injection time, the shear strain rate of the melt can be optimized, thereby affecting the filling pressure and molding effect.

5.1 Relationship between injection time and pressure

Reducing the injection time will boost the shear strain rate in the melt, therefore improving the filling efficiency. Too short an injection time, though, may cause uneven filling, hence it must be modified depending on the particular circumstances to find the best injection time.

6. Advantages of IMD Injection Molding

6.1 Cost savings

The IMD injection molding process reduces the cost of multiple processing and reduces the cost of materials and inks by completing injection molding in the same process. This effect significantly improves production efficiency.

6.2 Product technology improvement

IMD injection molding can print thin films on curved or uneven surfaces, providing a variety of visual effects, such as bite, bright surface, rough surface, etc. This technological improvement makes the product more competitive in the market.

6.3 Durability

IMD injection molded products have good wear resistance, scratch resistance and chemical resistance, effectively protecting the product appearance and extending the product life.

6.4 High output efficiency

IMD injection molding achieves consistency and standardization in the production process, accurate positioning, and effectively improves the yield and production efficiency.

6.5 Creativity

IMD injection molding allows the use of films or other materials for the design of complex appearance patterns, increasing the surface touch of the product and further enriching the user experience.

6.6 Environmental protection and energy saving

The IMD injection molding process meets environmental protection standards and reduces the impact on the environment. During the production process, IMD injection molding not only saves energy, but also reduces the demand for production space and reduces inventory risks.