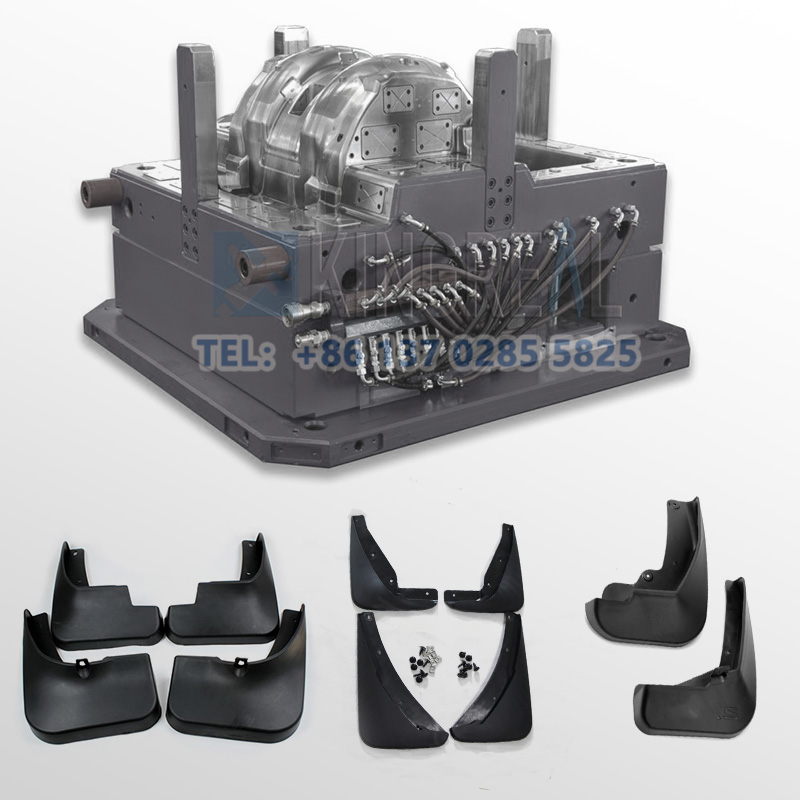

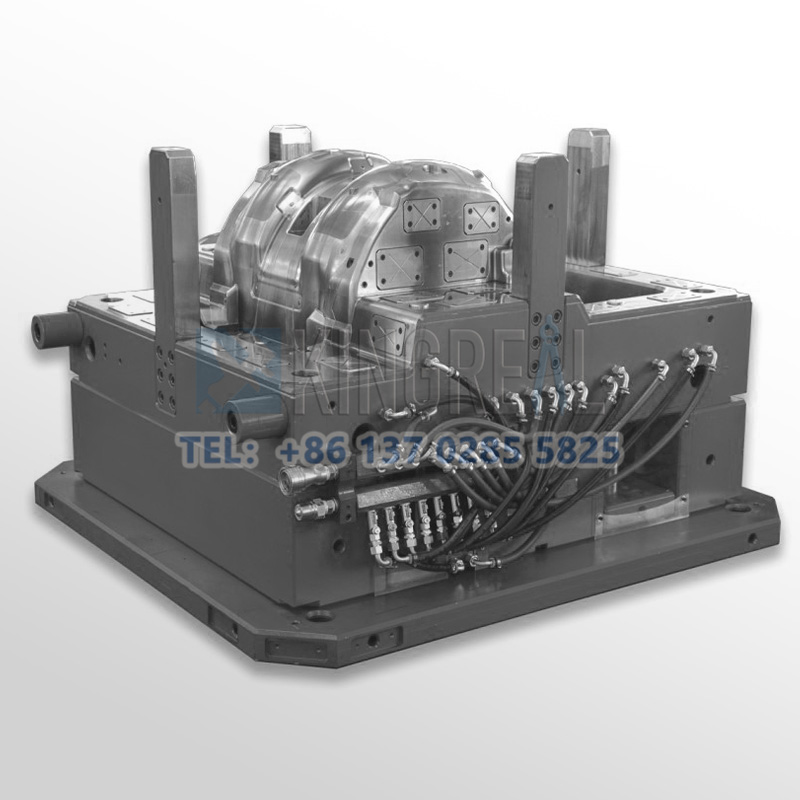

KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825

Auto car fender molds are known as the "mother of industry", and their importance is self-evident. With the rapid development of car fender stamping die design and manufacturing technology, we have put forward higher requirements for plastic auto fender injection mold design and manufacturing. The continuous innovation of car fender stamping die processing technology, the increasing application of new materials, and the continuous improvement of the standardization and specialization of parts and components require us to adapt to the development of the auto car fender mold industry faster and more accurately.

Under the dual challenges of speed and precision, designers need to complete design tasks in a short time while ensuring the accuracy of the design. High-precision and cost-effective processing methods have become the first choice for design. The improvement of speed and precision complements each other and promotes each other.

Common problems and solutions for car fender stamping dies

When designing plastic auto fender injection mold structures, it is necessary to comprehensively consider various professional knowledge.

First, it is necessary to be familiar with the principles and manufacturing processes of auto car fender molds to ensure the rationality of the design. Secondly, it is necessary to understand the product type and its industry safety standards and testing standards to ensure the compliance of the design. In addition, it is necessary to master the relevant knowledge of plastic auto fender injection molding process, plastics and hardware in order to make reasonable designs according to material characteristics.

| 1 | Dimensional Variation of Auto Car Fender Molded Parts |

| 2 | Shrinkage Mark Problem |

| 3 | Stain Marks and Injection Lines |

| 4 | Voids |

The following are possible defects of auto car fender molded parts and their specific solutions.

1. Dimensional Variation of Auto Car Fender Molded Parts:

Characteristics:

During the plastic auto fender injection molding process, the weight and size of the product change beyond the production capacity of the car fender stamping die, plastic auto fender injection molding machine and plastic combination.

Possible causes:

(1) Uneven distribution of plastic in the injection cylinder.

(2) Large temperature fluctuations in the injection cylinder.

(3) Insufficient capacity of the auto car fender molding machine.

(4) Unstable injection pressure.

(5) Unstable screw reset, and inconsistent running time, solution viscosity and injection speed.

(6) Using a type of plastic that is not suitable for the car fender stamping die.

Remedies:

(1) Ensure that there is sufficient cooling water flowing through the hopper throat to maintain the correct temperature.

(2) Check whether the thermocouple is inferior or loose, and confirm whether its type is compatible with the temperature controller.

(4) Compare the injection volume and plasticizing capacity of the plastic auto fender injection molding machine and calibrate with the actual amount used.

(5) Confirm whether the molten hot material is supplied stably during each operation.

(6) Check the backflow prevention valve for leakage and replace it if necessary.

(7) Check the feed setting to ensure it is correct.

(8) Ensure that the screw is in a stable position when resetting, with an error of no more than 0.4mm.

(9) Check for inconsistencies in operating time.

(10) Use back pressure technology for adjustment.

(11) Check the hydraulic system to ensure that the oil temperature is within the appropriate range (25-60℃).

(12) Select the appropriate plastic type according to the car fender stamping die characteristics.

(13) Readjust the entire production process.

2. Shrinkage Mark Problem:

Characteristics

Shrinkage marks are usually related to surface marks and are the result of the plastic shrinking away from the car fender stamping diesurface.

Possible causes

(1) Improper melt temperature.

(2) Insufficient amount of plastic in the car fender stamping die cavity.

(3) Overheating of the car fender stamping die surface during the cooling stage.

(4) Unreasonable runner design and too small gate section.

(5) The car fender stamping die temperature does not match the plastic characteristics.

(6) Product structure design problems, such as ribs that are too high, too thick, or obviously uneven in thickness.

(7) Poor cooling effect, resulting in continued shrinkage of the product after demolding.

Remedial measures

(1) Adjust the temperature of the injection cylinder.

(2) Adjust the screw speed to obtain the appropriate screw surface speed.

(3) Increase the injection volume.

(4) Use the correct gasket; extend the screw forward time; increase the injection pressure and speed.

(5) Check whether the check valve is installed correctly to avoid pressure loss.

(6) Reduce the plastic auto fender injection mold surface temperature.

(7) Correct the flow channel design to reduce pressure loss; appropriately increase the gate cross-sectional size as needed.

(8) Adjust the car fender stamping die temperature according to the plastic properties and product structure.

(9) Optimize the product structure when feasible.

(10) Ensure that the product is adequately cooled.

3. Stain Marks and Injection Lines:

Characteristics

Usually appear in the gate area, showing as dull surface or visible stripes.

Possible causes

(1) The melt temperature is too high.

(2) The plastic auto fender injection mold filling speed is too fast.

(3) Improper temperature control.

(4) Plastic characteristics.

(5) There is cold material at the nozzle.

Remedies

(1). Increase the cooling time to allow the plastic to cool fully.

(2). Increase the amount of cooling water in the auto car fender mold.

(3). Adjust the injection pressure and screw position to ensure that the plastic fills the plastic auto fender injection mold evenly.

(4). Check whether the car fender stamping die is deformed or damaged and repair it in time.

4.Voids

Characteristics of auto car fender molded parts defects

In transparent plastic auto fender injection molded parts, voids usually appear as "air traps" but are not easy to detect in opaque plastics. These voids are related to the thickness of the auto car fender molded parts and often move away from the center of the plastic auto fender injection molded parts due to plastic shrinkage.

Possible causes of problems

(1). Insufficient car fender stamping die filling.

(2). Abnormal operation of the stop valve.

(3). Incomplete drying of the plastic.

(4). Excessive pre-molding or injection speed.

(5). Special materials require special equipment for production.

3. Remedial methods

(1). Increase the shot volume to ensure that the plastic auto fender injection mold is fully filled.

(2). Increase the injection pressure to promote plastic flow.

(3). Extend the screw forward time to improve plastic filling efficiency.

(4). Reduce the melt temperature to improve plastic fluidity.

(5). Adjust the injection speed according to the characteristics of the plastic, such as increasing the speed for non-crystalline plastics.

(6). Check whether the check valve is intact and ensure that it works normally.

(7). Optimize the drying conditions to ensure that the plastic is thoroughly dried.

(8). Appropriately reduce the screw speed, increase the back pressure or reduce the injection speed to improve the plastic fluidity and filling effect.