KINGREAL UNIVERSAL IND., LTD

Phone

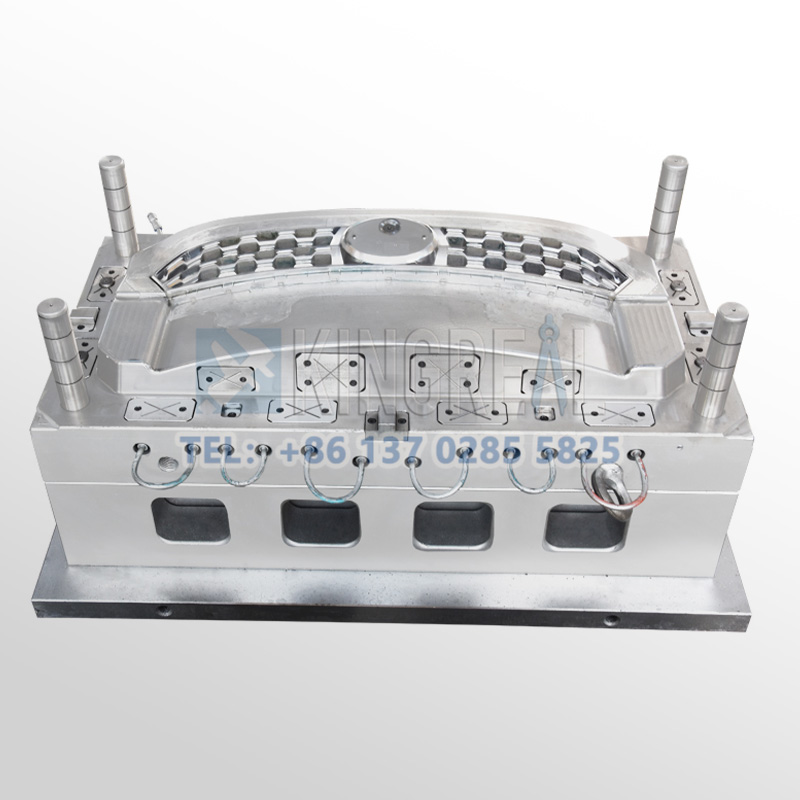

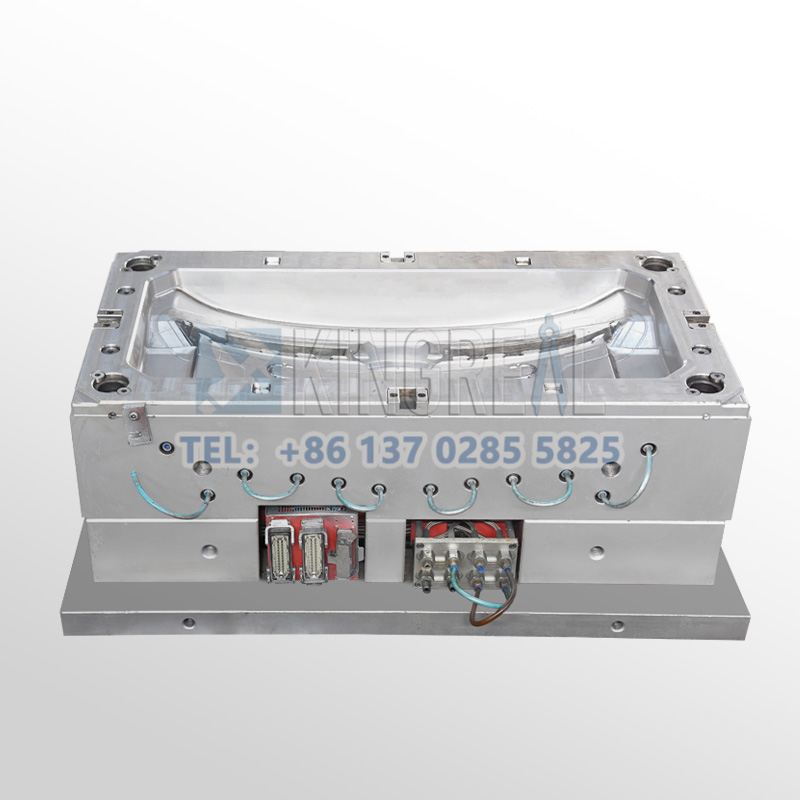

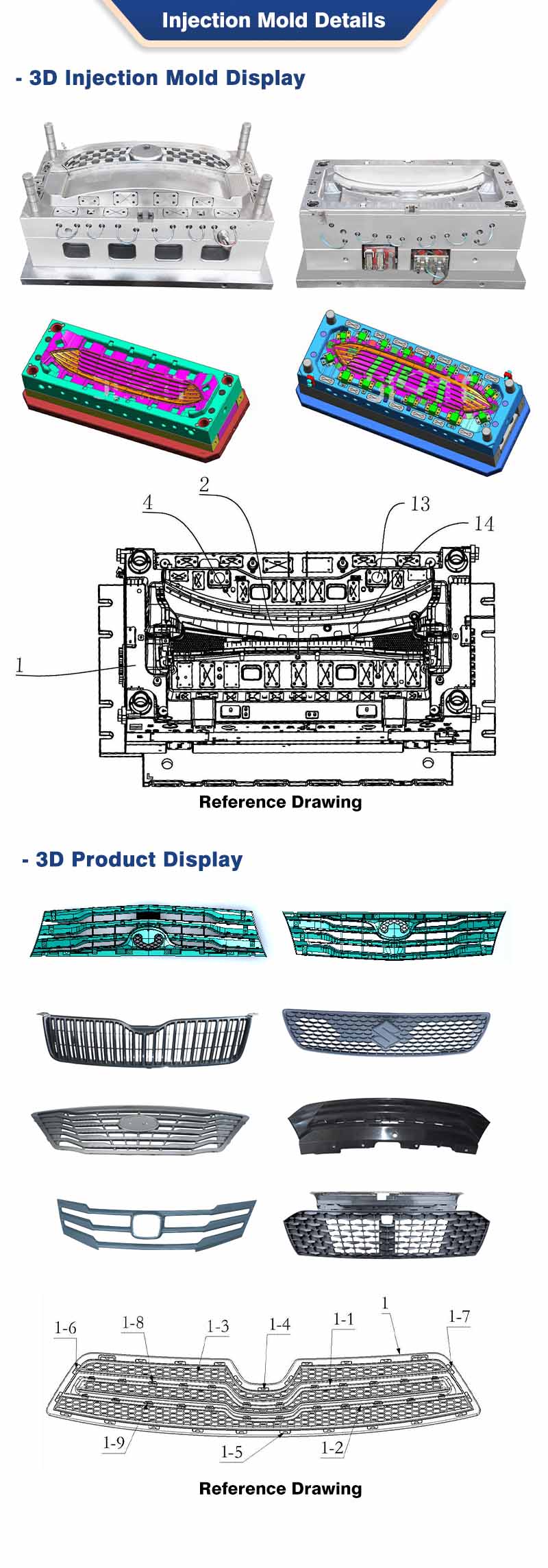

+86-13702855825Cooling grill injection mold is a tool for producing plastic products; It is also a tool to give plastic products complete structure and precise size. Vehicle cooling grille tooling is also a processing method used in mass production of parts, which is mainly used in industrial field. The process of radiator grille mould is to inject the heated and melted material into the cooling grill injection mold cavity from high pressure, and after cooling and curing, the molded product is obtained; According to the cooling grill injection molding characteristics, it can be divided into thermosetting plastic mold and thermoplastic plastic mold.

| 1 | About Radiator Grille Mould Processing |

| 2 | Main Steps of Radiator Grille Mould Processing |

| 3 | Matters Needing Attention in Radiator Grille Mould Processing |

| 4 | Common Problems and Solutions |

1. About Radiator Grille Mould Processing

Cooling grill injection mold processing is a key process to produce plastic parts, and it is also a complicated process. It involves many links such as design, material selection, manufacturing, testing and maintenance.

The processing of vehicle cooling grille tooling is to add plastic into the cooling grill injection mold first, then the radiator grille mould rotates continuously along two vertical axes and heats it. Under the action of gravity and heat energy, the plastic in the vehicle cooling grille tooling is gradually and evenly coated, melted and adhered to the whole surface of the radiator grille mould cavity, cooling grill injection molded into the required shape, and cooled and shaped.

High-quality radiator grille mould can significantly improve production efficiency and product quality.

2. Main Steps of Radiator Grille Mould Processing

2.1 Requirements Analysis and Design

Product requirements: understand the product specifications, functional requirements and use environment provided by customers.

Mold requirements: determine the mold type, material, production batch and other requirements.

CAD modeling: use computer aided design (CAD) software to model the vehicle cooling grille tooling in three dimensions and design various parts of the cooling grill injection mold.

Runner design: design a reasonable runner system to ensure that the molten plastic flows evenly into the vehicle cooling grille tooling cavity.

Cooling system design: design cooling channels to ensure that the radiator grille mould can effectively dissipate heat and improve production efficiency.

Exhaust design: design the exhaust system to eliminate the gas in the vehicle cooling grille tooling and avoid defects such as air holes.

2.2 Material preparation

Material selection: Choose suitable radiator grille mould steel (such as P20, H13, etc.) or other materials (such as aluminum) according to the use requirements of the cooling grill injection mold.

Material procurement: purchase raw materials that meet the requirements and conduct acceptance.

2.3 processing and manufacturing

Rough machining:

Cutting and milling: using lathes, milling machines and other equipment to preliminarily process the die block to form a rough shape.

Drilling and grooving: machining the hole position and grooving of the die to prepare for the subsequent finishing.

CNC machining: Use CNC machine tools for precision machining to ensure the size and surface quality of the cooling grill injection mold.

Grinding: Grinding the vehicle cooling grille tooling surface to achieve the required smoothness and dimensional accuracy.

Heat treatment:

Hardening treatment: heat treatment (such as quenching and fire) is carried out to improve the hardness and wear resistance of the cooling grill injection mold as needed.

Assembly of parts: Assemble all parts of the vehicle cooling grille tooling to ensure normal cooperation and function.

Debugging: Conduct radiator grille mould trial and debugging to check its performance and stability.

2.4 Detection and testing

Size detection: use precision measuring tools (such as CMM) to detect the size and tolerance of the cooling grill injection mold.

Functional test: the actual injection test of the vehicle cooling grille tooling is carried out to check the production performance and finished product quality of the radiator grille mould.

Correction and adjustment: according to the test results, make necessary corrections and adjustments to the cooling grill injection mold to meet the design requirements.

2.5 Delivery and maintenance

Delivery: deliver the tested cooling grill injection mold to the customer, and provide instructions and maintenance suggestions.

Maintenance: check and maintain the radiator grille mould regularly, deal with wear and damage, and extend the service life of the vehicle cooling grille tooling.

3. Matters Needing Attention in Radiator Grille Mould Processing

Design accuracy: ensure that the vehicle cooling grille tooling design meets the product requirements and avoid design defects affecting the production quality.

Material selection: Select suitable mold materials to meet the requirements of cooling grill injection mold strength, wear resistance and heat resistance.

Machining accuracy: adopt advanced machining technology and equipment to ensure the size and surface quality of the radiator grille mould.

Cooling and exhaust: Reasonable design of cooling system and exhaust system can improve the production efficiency and product quality of cooling grill injection molds.

Detection means: use precise detection equipment to ensure that all parameters of the vehicle cooling grille tooling meet the standards.

Maintenance: Maintain the radiator grille mould regularly, deal with wear and damage, and keep the cooling grill injection mold in good condition.

4. Common Problems and Solutions

(1)Problem: There are bubbles or air holes on the surface of the vehicle cooling grille tooling.

Solution: Check the exhaust system to ensure that the gas can be discharged smoothly. Adjust the injection parameters to reduce the air content of plastic.

(2)Problem: The size of cooling grill injection molded products is inconsistent.

Solution: Check the dimensional accuracy and processing technology of the cooling grill injection mold to ensure that the tolerance of the radiator grille mould meets the requirements. Adjust the parameters of cooling grill injection molding machine, such as injection pressure and cooling time.

(3)Problem: The vehicle cooling grille tooling is worn or damaged.

Solution: Maintain the cooling grill injection mold regularly and repair the worn parts in time. Wear-resistant materials, increase the durability of the radiator grille mould.