KINGREAL UNIVERSAL IND., LTD

Phone

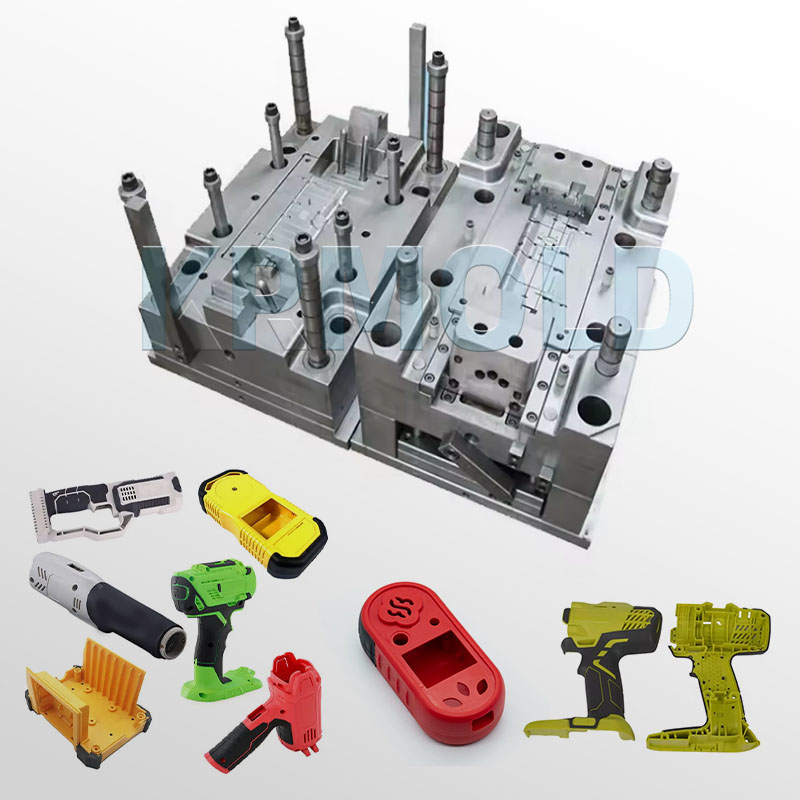

+86-13702855825TPE injection molding is a common form of plastic injection molding, which is widely used in the manufacture of various products. Many people are curious about the process techniques of TPE injection moulding, especially how to improve production efficiency and product quality. Today, KRMOLD will reveal the key elements and techniques of TPE injection molding in detail. If you are interested in TPE injection moulding, or need to know more about TPE injection molds, please come to consult KRMOLD. As a plastic injection mold manufacturer with more than 20 years of rich experience, I believe KRMOLD can answer your doubts one by one. |  |

| 1 | Product Surface Treatment |

| 2 | Advantages of Low-temperature TPE Injection Molding |

| 3 | Reasonable Temperature Setting |

| 4 | Adjustment of Holding Pressure |

| 5 | Regulation of Injection Speed |

1. Product Surface Treatment

1.1The importance of drying Before TPE injection molding, it is very important to ensure that the surface of the product is as strict as required. Generally speaking, drying must be carried out before TPE injection moulding. Drying usually adopts hopper drying, the temperature is set at 7080℃, the time is 2 hours, or tray drying, the temperature is 80100℃, and the time is 1 hour. When drying on the tray, attention should be paid to the thickness of the material layer, which is generally not more than 50mm. This is because thicker material layers are not easy to dry evenly, which may lead to the failure to effectively remove internal moisture, thus affecting the quality of TPE injection moulding. If bubbles appear on the surface of the injection-molded material strip, or when the material strip is cut, it is found that there are holes inside, or scattered silver wires appear on the surface of the product, it can be determined that the TPE raw material contains too much water. This situation not only affects the appearance quality of the product, but may also have a negative impact on the physical properties. Therefore, drying treatment is an important step in the TPE injection molding process. |  |

2. Advantages of Low-temperature TPE Injection Molding

2.1 Choose a suitable TPE injection molding temperature

In the TPE injection molding process, it is an effective strategy to use low-temperature TPE injection moulding as much as possible. Under the premise of ensuring the plasticization quality, lowering the extrusion temperature can help reduce thermal decomposition and damage to material properties. In addition, by increasing the injection pressure and screw speed to reduce the melt viscosity, the purpose of improving fluidity can also be achieved. This method can effectively improve production efficiency.

When the surface of the material strip injected from the nozzle is smooth and shiny, it means that the plasticization quality is relatively good. If the material strip injected from the nozzle is very bright, it can be judged that the barrel temperature can be lowered. Low temperature TPE injection molding can not only reduce cooling time, but also improve customer production efficiency, reduce energy consumption, and meet environmental protection requirements.

3. Reasonable Temperature Setting

3.1 Optimization of temperature distribution In TPE injection molding, reasonable temperature setting is crucial. The upper parabola temperature setting, that is, the temperature in the middle zone of the screw is the highest, the feeding section is slightly lower, and the nozzle temperature is slightly lower. A typical temperature setting is: feeding section 150-170℃, middle 170-180℃, front 190~200℃, nozzle 180℃. This temperature setting is only for reference data, and the specific temperature should be adjusted appropriately according to the physical properties of different TPE materials. If the product content is found to be bulging (gas is wrapped inside), or the gate is easy to break during demolding, you can refer to the above temperature setting for adjustment. Appropriate temperature setting can not only improve molding quality, but also reduce the occurrence of defects. |  |

4. Adjustment of Holding Pressure

4.1 Selection of holding pressure

During the TPE injection moulding process, the holding pressure should be as small as possible. Usually, the holding pressure is smaller than the injection pressure. The holding time can be determined by weighing the product, and the weight of the product will not increase, or the shrinkage mark accepted by the customer. If it is found that the gate is easy to break during demolding, and the problem cannot be solved by adjusting the temperature and injection speed, then reducing the holding pressure should be a feasible solution.

Reasonable holding pressure setting can reduce the internal stress of the product, reduce the risk of deformation, and thus improve the qualified rate of the finished product. The optimization of this process is an important step to achieve high-quality TPE injection moulding.

5. Regulation of Injection Speed

5.1 Grading of injection speed When performing several levels of injection, the speed should be from slow to fast. This method helps to effectively discharge the gas inside the mold and reduce the situation of gas encapsulation. If there is gas encapsulation (internal bulging) or dents inside the product, and adjusting the temperature and holding pressure still does not work, this method can be considered. By reasonably controlling the injection speed, not only the success rate of TPE injection molding can be improved, but also the surface quality of the product can be improved. This is especially important for high-standard TPE products, which can ensure the competitiveness of the product in the market. |  |

In summary, the process skills ofTPE injection molding involve many aspects, from drying treatment to temperature setting, from the adjustment of holding pressure to the control of injection speed, each link has an important impact on the quality of the final product. Through reasonable process design and strict process control, the stability and consistency of TPE injection molded products can be ensured.

If you have a deeper interest in TPE injection moulding and its process skills, or want to get more information about TPE injection molds, please feel free to consult KRMOLD. As a mold manufacturer with more than 20 years of experience, we are committed to providing customers with high-quality TPE injection mold solutions to help customers stand out in the fierce market competition. We look forward to working with you to explore the infinite possibilities of TPE injection moulding.