KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825

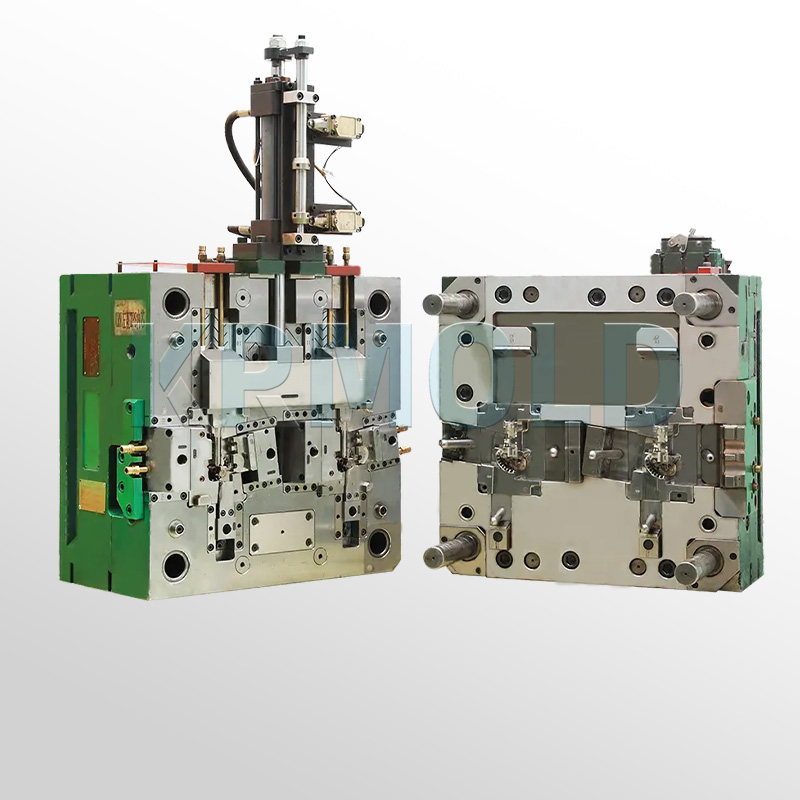

"Insert injection molding is a process in which the insert is pre-fixed in the appropriate position in the plastic injection mold, and then the plastic is injected to form the mold. After the plastic injection mold is opened, the insert is tightly buried in the plastic by the cooled and solidified plastic to obtain a product with inserts such as threads and electrodes.

During insert molding, it is generally formed in batches, so the method and process of insert injection molding are very important. If it is not processed according to the specified requirements, the plastic injection mold will be damaged. For this reason, KRMOLD introduces the analysis of the insert molding process."

| 1 | Process Flow of Insert Injection Molding |

| 2 | Analysis of Injection Molding Process |

| 3 | Advantages of Insert Molding |

1.Process Flow of Insert Molding

Insert preparation: Pre-formed inserts can be made of metal, ceramic or other types of plastics, such as metal fasteners, connectors, etc., and are used to merge with plastic parts.

Insert placement: The insert is accurately placed in the mold cavity by manual or automatic means to ensure its correct positioning and alignment.

Plastic injection: After the insert is fixed, the molten plastic is injected into the mold, and the plastic covers the insert and forms the shape of the final product. The high temperature and pressure during the insert injection molding process ensure that the plastic and the insert are firmly combined.

Cooling and demolding: After the plastic cools and solidifies, the mold opens and the finished product is ejected. At this point, the insert is firmly wrapped in the plastic to form a complete part.

2.Analysis of Injection Molding Process

1) Raw materials generally do not need to be dried, and in some cases, they are baked at 80℃ for 2 hours;

2) The insert injection molding temperature range is large, and the heating melting and curing speed are fast, so the insert molding cycle is generally short; Temperature parameters: The barrel temperature is about 200℃. If the material temperature is too high, silver wires are likely to appear, and if the material temperature is too low, the transparency will be poor;

3) Mold temperature control: The mold temperature is generally 50-80℃;

4) GPPS has good fluidity, and high pressure is not required in beer insert molding (usually the injection pressure is about 10Mpa), so as not to increase the internal stress of the plastic part due to excessive pressure, which may cause cracking (especially after the paint decoration process);

5) The injection speed should be appropriately high to reduce the water inclusion mark, but because the injection speed is greatly affected by the injection pressure, too high a speed may cause problems such as flashing or sticking to the mold when ejecting, and whitening and cracking when ejecting;

6) Appropriate back pressure: If the back pressure is too low, the screw is easy to overflow with air, the density of the particles in the barrel is small, and the plasticization effect of the particles is not good. Affects the apparent quality of the rubber parts (generally the back pressure is 10-20kg/cm²); g) The fine water inlet on the mold is generally designed to be 0.8-1.0mm. h) Glass fiber reinforced PS-GF30, barrel temperature is 180~275, mold temperature is 20~80, insert molding shrinkage is 0.1~0.2. Density is 1.29/cm³.

3.Advantages of Insert Molding

1) The combination of plastic's easy formability and elasticity with metal's rigidity, strength and heat resistance can be used to make complex and delicate metal-plastic integrated products; reduce the size and weight of the product;

2) The combination of plastic's insulation and metal's conductivity can make the molded products meet the basic functions of electrical products; they can also meet certain special requirements, such as magnetic conductivity, wear resistance and fastening;

3) Adding metal inserts to plastic can improve the strength of plastic parts;

4)Insert injection molding increases product design flexibility and provides new possibilities for the combination of plastics, metals and other parts;

5) Avoiding secondary processes such as hot melting, welding and riveting has the opportunity to shorten assembly time and cost;

6) Inserts are not limited to metal, but also include cloth, Paper, wire, plastic, glass, wood, coils, electrical parts and plastic parts;

7) For rigid molded products and curved elastic molded products on rubber sealing pads, after being made into an integrated product through insert molding on the substrate, the complicated operation of arranging the sealing ring can be omitted, making the automation combination of the subsequent process easier;

8) Because it is a combination of molten plastic and metal inserts, compared with the press-in insert molding method, the metal insert gap can be designed to be narrower, and the product reliability is higher; it is easier to pass vibration tests;

9) Choose appropriate plastics and insert injection molding conditions, that is, for products that are easy to deform and break (such as glass, coils, electrical parts, etc.), they can also be sealed and fixed by plastic;

10) Choose the appropriate mold structure, and the insert can also be completely sealed in the plastic.

11) The combination of vertical insert molding machine with manipulator, insert product arrangement device, etc., most insert molding projects can be automated.

If you want to know more about insert injection, please consult KRMOLD! We are happy to answer any questions you may have about insert molding.