KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825ABS injection molding is a process widely used in the manufacture of plastic products, and the processing of ABS injection molds is an indispensable part of this process.

The function of ABS injection molds is to mold ABS (acrylonitrile-butadiene-styrene) plastics into various complex shapes through heating and pressure.

In this article, KRMOLD will discuss in detail the driving methods of ABS injection molds processing, including pneumatic forming, electro-hydraulic drive and electromechanical drive, and deeply analyze how these driving methods affect the efficiency and quality of ABS injection molding. |  |

| 1 | Basic Principles of ABS Injection Molds Processing |

| 2 | Driving Mode of ABS Injection Molds |

| 3 | Impact of Drive Mode on ABS Injection Molding |

| 4 | Future Development Trends |

1. Basic Principles of ABS Injection Molds Processing

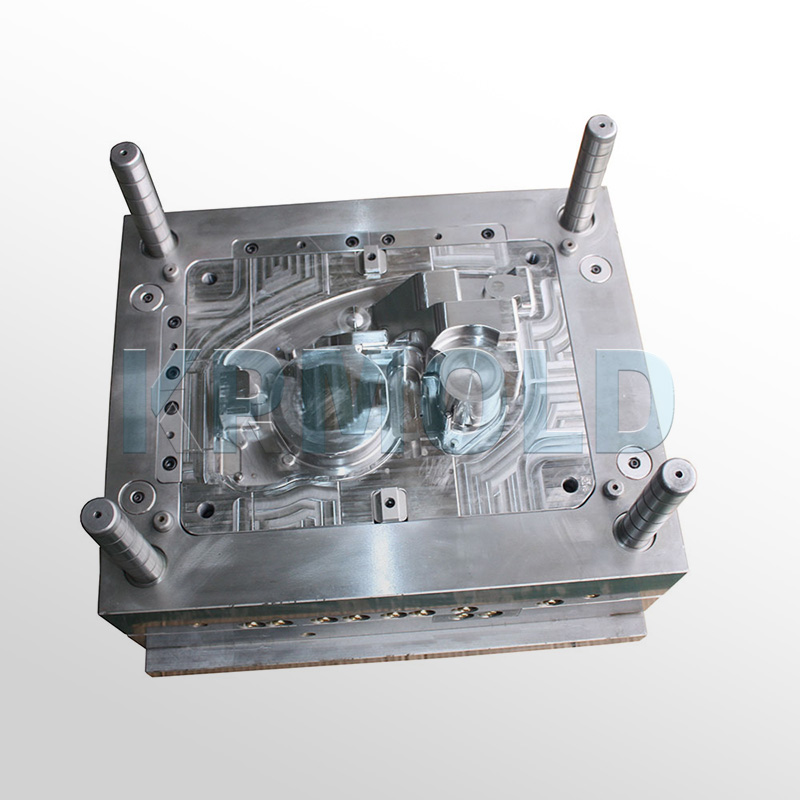

When performing ABS injection molding, ABS material is first added to the mold. The mold rotates and heats continuously along two vertical axes. Under the action of gravity and heat energy, the plastic gradually melts and is evenly coated on the entire surface of the mold cavity, and finally molded into the desired shape.

After cooling, the mold is opened and the molded ABS parts can be taken out. The choice of driving method directly affects the processing accuracy and production efficiency of ABS injection molds.

2. Driving Mode of ABS Injection Molds

2.1 Air pressure forming

Air pressure forming is mainly used for vacuum forming and blow molding. During the air pressure forming process, when the ABS injection molds is in a fixed state, a certain negative pressure is generated by the air pump to suck the ABS plastic sheet onto the mold surface to form a part.

For blow molding, the air pump generates air pressure to blow the hot melt plastic or glass part blank into the mold cavity, causing it to expand, deform, and adhere to the mold cavity surface, and finally form the required part.

The advantage of air pressure forming is that it can quickly form complex part shapes and is suitable for mass production. However, its disadvantage is that it has high requirements for the sealing and air pressure control of the ABS injection molds. If it is not handled properly, it is easy to cause ABS injection molding defects.

2.2 Electro-hydraulic drive

Electro-hydraulic drive is to drive a hydraulic pump or water pump through an electric motor to generate hydraulic pressure and water pressure. Through the liquid delivery and control system, a certain rated pressure is generated to drive the moving part of the ABS injection molds.

Specifically, the working principle of electro-hydraulic drive is to use a hydraulic cylinder or piston to move the movable mold relative to the fixed mold in a directional translation.

The advantages of this drive mode are its high efficiency and controllability, which can provide stable pressure during the ABS injection molding process, thereby ensuring the processing accuracy of the ABS injection molds.

In addition, the electro-hydraulic drive system has a fast response speed and is suitable for the needs of rapid prototyping.

2.3 Electromechanical Drive

Electromechanical drive usually drives the moving part of the ABS injection molds by providing power and rotational motion through an electric motor. Common electromechanical drive equipment includes stamping machines, friction presses, and roll forging machines.

Through transmission mechanisms such as sliders, electromechanical drive can achieve precise movement of the ABS injection molds, and effectively transmit the driving force to the ABS injection molds, enabling it to effectively form the material.

The advantages of electromechanical drive are mature technology, simple maintenance, and the ability to achieve high repeatability, which is crucial to ensuring the quality of ABS injection molded products.

3. Impact of Drive Mode on ABS Injection Molding

3.1 Processing accuracy

Processing accuracy is a key indicator in the ABS injection molding process and directly affects the quality of the product. Electro-hydraulic drive can usually achieve higher processing accuracy due to its efficient pressure control and stability. However, pneumatic forming may cause the molding accuracy to decrease due to air pressure fluctuations.

3.2 Molding speed

Molding speed is an important factor in measuring production efficiency. Electromechanical drive can complete the opening and closing, injection and cooling processes of ABS injection molds in a short time due to its fast response characteristics, thereby improving production efficiency. Although pneumatic forming can form quickly, it may be relatively slow in cooling and removing parts.

3.3 Adaptability

Different drive modes also differ in adaptability. For example, electro-hydraulic drive systems are suitable for high-precision parts with complex shapes, while pneumatic forming is suitable for large-area, thin-walled parts.

Choosing the right drive mode according to the specific requirements of the product can better meet production needs.

4. Future Development Trends

With the development of science and technology, the drive mode of ABS injection molds processing is also evolving. More new drive technologies may appear in the future, such as intelligent drive and energy-saving drive. These new technologies will further improve the efficiency and quality of ABS injection molding, while reducing energy consumption and production costs.

For example, the intelligent drive system can automatically adjust the working state of the ABS injection molds through real-time monitoring and data analysis, thereby achieving more efficient production.

In addition, the application of energy-saving drive technology will reduce the energy consumption of ABS injection molds, which meets the requirements of sustainable development.

In summary, the influence of the drive mode of ABS injection molds processing on the molding process cannot be ignored. Pneumatic forming, electro-hydraulic drive and electromechanical drive each have unique advantages and applicable scenarios.

Choosing a suitable drive mode can not only improve production efficiency, but also ensure the quality of parts.

In the future development, with the continuous emergence of new technologies, ABS injection molding will usher in a broader prospect. Through continuous optimization and innovation, KRMPLD believes that ABS injection molds processing will bring more possibilities for the production of plastic products.