KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Car front bumper mould are important process equipment for producing various industrial products. With the rapid development of the plastics industry, the promotion and application of plastic products in aviation, aerospace, electronics, machinery, shipbuilding, automobile and other industrial fields have put higher and higher requirements on products and car bumper Injection molds. Traditional mold design methods can no longer meet today's requirements. Compared with traditional mold design, CAE technology has great advantages in improving productivity, ensuring product quality, reducing costs, and reducing labor intensity.

| 1 | Importance of Car Bumper Injection Molds to Automotive Industry |

| 2 | Common Structures of Car Bumper Injection Molds |

| 3 | Advantages of Car Bumper Injection Molding in Automotive Applications |

| 4 | Production Applications of Automotive Bumper Mold Design |

1. Importance of Car Bumper Injection Molds to Automotive Industry

Automotive bumper mold design can produce complex automotive parts by injecting molten plastic into car bumper Injection molds to achieve the integration and lightweight of automobiles.

This not only improves production efficiency and delivery speed, but also reduces the consumption of resources and energy.

In today's automobile manufacturing industry, the importance of car front bumper mould is as unshakable as a cornerstone.

As a key tool for obtaining the required products in industrial production, molds play a vital role in the field of automobile manufacturing.

It is no exaggeration to say that the production and processing of most automobile parts cannot be separated from the help of automotive bumper mold designs.

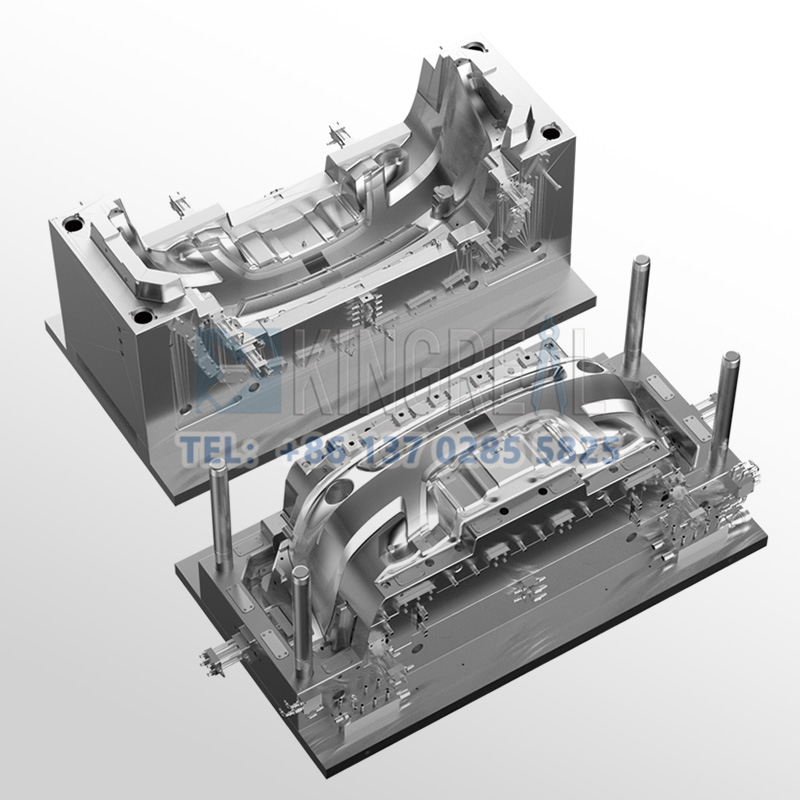

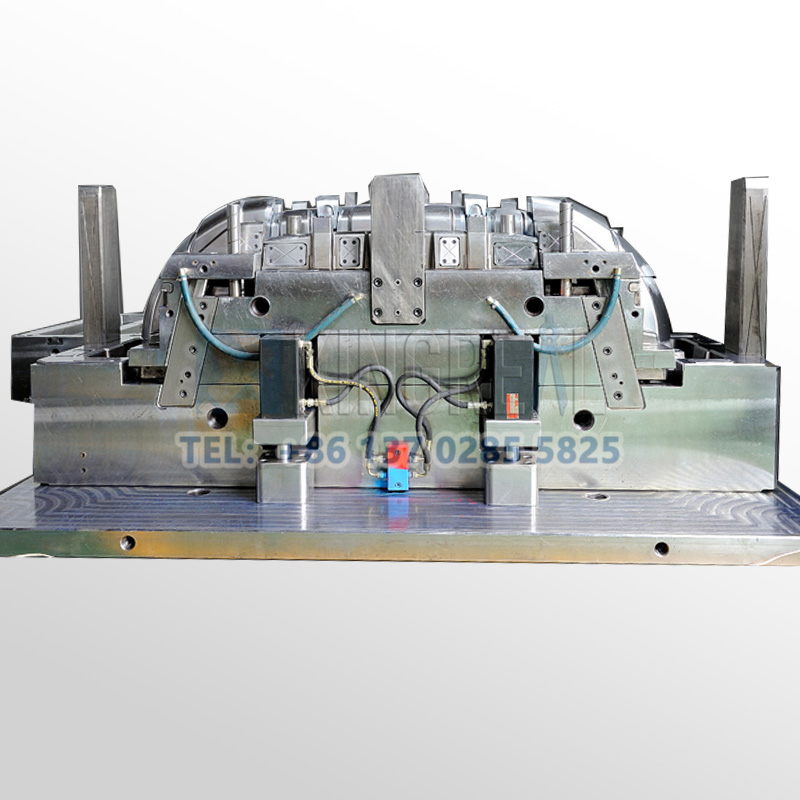

2. Common Structures of Car Bumper Injection Molds

Automotive bumper mold designs also play an important role in automobile manufacturing, and their different parts have specific structural designs.

For example, the rear mold position of the steering column of the car is designed with cooling water due to the large car bumper Injection molding area to ensure that the plastic parts are evenly cooled and avoid local overheating.

For parts weighing more than 8KG, process lifting holes are also designed to facilitate the assembly of fitters.

At the same time, the slider is designed with process screw holes and conical surface positioning to ensure that the clamping line of the plastic parts is uniform and delicate, meeting the quality requirements of the automotive appearance parts.

There are also many key points to pay attention to when designing the rear mold oblique position of the rearview mirror seat of the car.

For the inclined slider that pulls the core in the up and down direction of the Z axis, the inclination of the inclined slider A must be greater than the angle of the inclined slider B by more than 2 degrees to avoid undercuts and pulling plastic parts.

The design of the cooling water, spring, etc. of the inclined slider must be parallel to the core pulling angle of the inclined slider for easy processing.

When ordering an inclined slider, it is necessary to order the embryo along the inclination direction of the inclined slider to facilitate subsequent processing.

The inclined slider is driven by the inclined guide column. The larger the inclined slider is, the greater the torque is. Therefore, the inclined guide column should be designed to be as sturdy as possible. The SKD61 ejector is used for diameters less than 20, and SUJ2 is used for diameters above 25, and high-frequency quenching is performed.

When designing the core-pulling structure of the slider, try to use the original body to leave the shovel base to reduce the mold cost.

The structure of the three-plate front mold position of the rearview mirror seat of the car is relatively complex.

The automotive bumper mold design slider is a fixed mold tunnel inclined slider structure, which is driven by the opening and closing of the fixed mold panel and the A plate and the inclined guide column.

The core-pulling stroke is large, and the core-pulling is at a certain angle to the Z axis. The design of the inclined guide column is crucial.

In order to prevent the slider from retreating during injection, a wear-resistant block is designed on the shovel base, which is at a certain angle to the slider protection plate, and a backhoe structure is designed.

The design of the slider insert and the slider seat takes into account the convenience of positioning, processing and assembly.

Special-shaped inserts and insert pins are designed in the slider to solve the problem of trapped air.

The slider is also designed with cooling water and multiple wear-resistant blocks to ensure a smooth and reliable core pulling process.

The side core pulling mechanism of the automobile headlight lens spring plate with the rear car bumper Injection mold position is the most important and complex structure in this mold.

There are many core pullings and the directions are inconsistent. There are both outer core pulling and inner core pulling, and there are core pulling towards the center of the automotive bumper mold design.

When designing the side core pulling mechanism, the outer oblique slider is designed with an insertion angle, the inner core pulling is designed with a wear-resistant block and a reverse locking structure, the rounded corners are designed on the inside of the T-slot, the support column is designed to strengthen the mold strength, and the slider head is designed with a conical surface and fixed with the fixed mold A plate. Advanced structures such as plate, have achieved satisfactory molding results.

3. Advantages of Car Bumper Injection Molding in Automotive Applications

Automotive bumper mold designing is a mature production process in which automotive car bumper Injection mold manufacturers inject molten plastic material into the car front bumper mould cavity. The molten plastic then cools and hardens, and the manufacturer extracts the finished product. Although the automotive bumper mold design process is critical and challenging (poorly designed car bumper Injection molds can lead to defects), car front bumper moulding itself is a reliable method for producing solid plastic parts with a high-quality finish.

Here are a few reasons why the process is beneficial for automotive plastic part production:

(1) Repeatability

In the automotive industry, repeatability—or the ability to consistently produce the same part—is critical. Since automotive bumper mold designing typically relies on a solid metal mold, the final molded automotive part produced using that mold is virtually identical. Certain factors can affect car bumper Injection molding, but if the car front bumper mould has a good design and finishing, automotive bumper mold designing is a highly repeatable process.

(2) Scale and Cost

The car bumper Injection mold manufacturing process can be an expensive process due to the cost of the automotive bumper mold design. However, it is still a highly scalable process, and its overall cost decreases as manufacturers make more parts. For mass production applications, car front bumper moulding is therefore beneficial to manufacturers. However, for anything that is not mass production, injection mold costs may inhibit the cost efficiency of the process.

(3) Material Availability

A significant advantage of using car bumper Injection molding in automotive production is that the process is compatible with a wide range of rigid, flexible, and rubber plastics. Manufacturers use a variety of different polymers for a variety of applications in the automotive industry, including ABS, polypropylene, acrylic, acetal, nylon, polycarbonate, and more.

(4) High Precision and Surface Finish

Automotive bumper mold designing is ideal for producing plastic parts with relatively simple geometries that achieve high surface finish quality. Manufacturers have many surface finish options when producing parts, including various surface textures (such as glossy, rough, or matte) that are applied directly to the mold rather than to the molded part. However, different plastic materials can also affect the final surface finish.

(5) Color Options

In car bumper Injection molding, it is easy to modify the color of the molded automotive part to fit the vehicle's color scheme. Unlike other processes, car front bumper moulding allows you to mix dyes with the raw material particles before manufacturing begins. This produces solid, consistent coloring after automotive bumper mold designing is complete without the need for painting or tinting.

(6) Rapid Prototyping with Rapid Tooling

Although automotive manufacturers use car front bumper moulding extensively to mass produce automotive parts, they also use it as a prototyping tool. By using rapid tooling to create fast, low-cost aluminum automotive bumper mold designs—often through additive manufacturing or CNC machining—car bumper Injection mold makers can complete the production of low-volume prototype automotive parts much faster than with traditional (steel) molds. |  |

4. Production Applications of Automotive Bumper Mold Design

In the automotive world, car bumper Injection molding is one of the primary methods manufacturers use to form plastic parts. However, it would be difficult to list the plastic parts in a car that are produced using car front bumper moulding, so we will look at some of the main components.

1

Under the Hood Components

Over the past two decades or so, manufacturers have transitioned to plastics for many of the under-the-hood components that were previously made of metal. For these applications, strong polymers such as ABS, nylon, and PET are common. However, manufacturers now use car bumper Injection molding to make parts such as cylinder head covers and oil pans. This method is less heavy and less expensive than metal parts.

2

Exterior Components

Automotive bumper mold designing is a well-established process for many automotive exterior parts, including fenders, grilles, bumpers, door panels, floor rails, light covers, and more. Splash guards are a good example of the durability of car bumper Injection molded parts. In addition, parts that protect the car from road debris and minimize splashes are usually made of rubber or other durable and flexible materials.

3

Interior Components

Manufacturers also use car bumper Injection molding to produce many automotive interior parts. They include instrument components, interior surfaces, dashboard panels, door handles, glove boxes, air vents, etc. In addition, they also use automotive bumper mold designing to produce decorative plastic elements.