KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content:

Introduction to Cosmetic Container Injection Mold

Cosmetic Container Injection Mold Design and Manufacturing

Material Classification for Cosmetic Container Injection Molds

Cosmetic Container Injection Mold Development and Economic Considerations

"In the modern cosmetics industry, the appearance and functionality of cosmetic containers are paramount. Cosmetic container injection molds are the key tools for achieving this goal. This article will delve into the material classification of cosmetic container plastic injection molds and analyze the characteristics and applications of various materials."

1.Introduction to Cosmetic Container Injection Mold

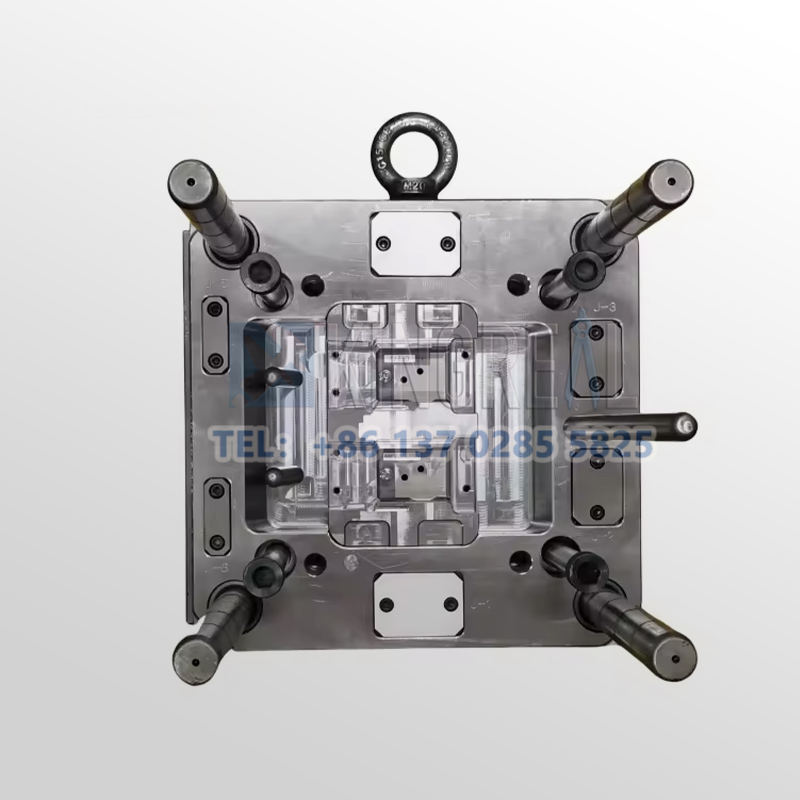

Mainly used to create several cosmetic containers including cream jars, lids, stoppers, gaskets, pump heads, and dust coverings, cosmetic container plastic injection molds manufacture many different kinds of cosmetic packaging. Thermoplastic component manufacturing most frequently uses these cosmetic container plastic injection molds, together with injection molding machines. The operating theory of an injection molding machine is to heat plastic until it melts, then keep heating it via a screw or column, allowing it to flow into the cosmetic container injection mold where it cools and hardens to create the ultimate form.

Usually constructed of high-quality plastic mold steel, an injection molding machine comprises a molding component, a gating system, guide components, an ejection device, a temperature control system, a venting mechanism, and support components. By accurate plastic injection molding, cosmetic container plastic injection molds produce a great range of cosmetic containers, easily handling anything from simple bottles to complex tubular items.

2.Cosmetic Container Injection Mold Design and Manufacturing

The form and size of the cosmetic container plastic injection mold have to guide adjustments to its design. Designers at KRMOLD utilize CAD program for three-dimensional modeling; the cosmetic container injection mold design must take into account the product's accuracy, surface finish, and moldability. Material selection, CNC machining, EDM cutting, and assembly are among the many stages in cosmetic container plastic injection molding's production process. Every stage calls exacting standards to guarantee the accuracy and lifetime of the cosmetic container injection mold, hence assuring the quality and stability of the finished product.

3.Material Classification for Cosmetic Container Injection Molds

The choice of container material has a direct impact on product performance and consumer experience in the cosmetic sector. Understanding the primary material categories for cosmetic container plastic injection mold is therefore rather important.

3.1 Cosmetic container injection mold for plastic bottle materials

Plastic bottles typically use the following materials:

-PP (Polypropylene): Has good heat and chemical resistance, widely used in cosmetic containers.

-PE (Polyethylene): Suitable for low-cost tubes and bottles, possessing excellent toughness and plasticity.

-PET (Polyethylene terephthalate): An environmentally friendly material, commonly used to make transparent cream and lotion bottles, offering excellent barrier properties.

-ABS (Acrylonitrile-Butadiene-Styrene copolymer): A thermoplastic resin, impact-resistant and with a glossy appearance, suitable for injection molding.

These plastic materials effectively meet the design requirements and performance needs of cosmetic containers during injection molding.

3.2 Cosmetic container injection mold for glass bottle materials

Usually reserved for premium skincare items and perfumes, glass bottles in the cosmetics industry are mostly classified as follows:

-Wide-mouth bottles: Suitable for creams, such as face creams and nail polishes. Equipped with anodized aluminum or plastic caps.

-Narrow-mouth bottles: Commonly used for liquids, such as lotions, generally equipped with pump heads.

Glass bottles offer high transparency and aesthetics, but are relatively expensive and require more care during transportation and storage to prevent breakage.

3.3 Cosmetic container injection mold for tube materials

Single-layer, double-layer, and five-layer tubes are among the structures that influence material selection for tubes; various layers of tubing have different gas barrier qualities and longevity:

-Single-layer tubing: Primarily low-cost, suitable for simple products.

-Double-layer tubing: Offers strong pressure and permeability resistance, suitable for most cosmetics.

-Five-layer tubing: Includes a barrier layer, suitable for high-end cosmetics, ensuring the stability and effectiveness of the contents.

3.4 Cosmetic container injection mold for dispenser and pump head materials

The choice of materials for dispensers and pump heads is crucial in cosmetic container plastic injection mold. Commonly used materials include:

-PP and PE: Lightweight and chemically resistant, suitable for dispensers of everyday skincare products.

-Aluminum or other metals: Used for spray nozzles in high-end perfume bottles, providing better sealing and a stylish design.

4. Cosmetic Container Injection Mold Development and Economic Considerations

Cosmetic container plastic injection mold development costs vary depending on the materials and complexity; specific prices need to be evaluated based on actual needs. Moreover, the type of molding material has a direct effect on the entire cost. Though expensive, high-quality stainless steel molds provide better production efficiency and longevity.

4.1 Production cycle for cosmetic container injection mold

The production cycle for cosmetic container plastic injection mold is depending on the materials chosen and the order size. For rush orders, businesses could have to work overtime to satisfy demand. Therefore, proper planning of production schedules and material procurement is crucial.

4.2 Quality control for cosmetic container plastic injection mold

To ensure the quality of the final product, companies must strictly control quality during the design and production of cosmetic container plastic injection molds. This includes material selection, monitoring of the production process, and inspection of finished products.

KRMOLD provides various cosmetic container injection molds, including vacuum series, cream jars, oral care products, sample series, lotion bottles, cushion compacts, and color cosmetics. For more information about cosmetic container plastic injection molds, please feel free to contact KRMOLD!