KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Overview of Factors Affecting Multi-cavity Injection Molding |

| 2 | Criticality of Multi Cavity Injection Molds Design |

| 3 | Multi Cavity Injection Molding Process Parameters |

| 4 | Plastic Material Selection |

| 5 | Environmental Factors for Multi Cavity Injection Molding |

| 6 | Strategies for Improving Precision Multi-Cavity Injection Molding Quality |

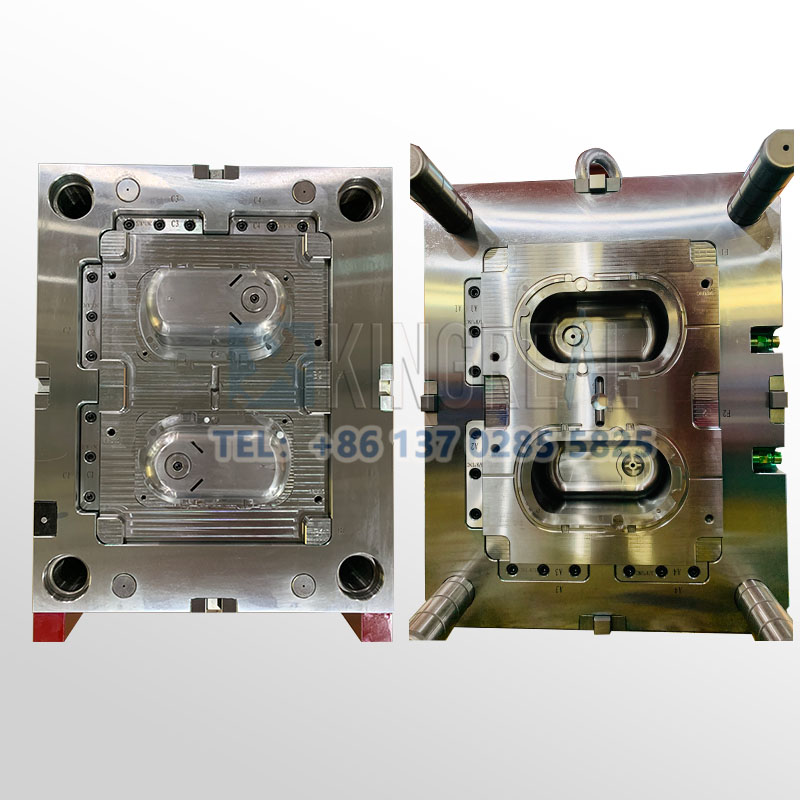

Multi-cavity injection molding uses several cavities inside the same plastic injection mold to allow the concurrent manufacturing of many goods. This layout provides major financial advantages for companies, speeds production cycles, and greatly increases production efficiency. Moreover, as plastic products have grown in popularity, the benefits of multi cavity injection molding have become very obvious, therefore it is the preferred technology for many companies. Moreover, multi cavity injection molding's great manufacturing efficiency allows it to be spread across more goods, hence lowering the price per product. Multi cavity injection molds additionally have more complicated design, therefore placing greater demands on mold materials and machining accuracy and hence producing more stable and dependable product quality.

So, what factors can affect precision molding during multi-cavity injection molding? In this article, KRMOLD will provide a detailed explanation of the factors that affect precision multi cavity injection molding, helping businesses address potential issues and improve product quality. |  |

1. Overview of Factors Affecting Multi-cavity Injection Molding

Designers must possess extensive design and injection molding experience and must consider the relationship between these factors and multi-cavity injection molding conditions, as well as their apparent effects. Many factors influence these processes, including injection pressure, cavity pressure, and filling speed; melt temperature and mold temperature; multi cavity injection molds structure, gate shape and distribution; gate cross-sectional area; part wall thickness; the content of reinforcing fillers in the plastic material; and the crystallinity and orientation of the plastic material. These factors interact to influence multi cavity injection molding quality and efficiency.

The influence of these variables also differs based on the type of plastic employed, as well as other multi-cavity injection molding factors like temperature, humidity, Post-molding modifications in the injection molding machine and ongoing crystallization For instance, during the multi-cavity injection molding process, different plastic polymers show different fluidity, shrinkage, and temperature sensitivity—therefore, material selection has to be done carefully.

2. Criticality of Multi Cavity Injection Molds Design

Among the factors influencing precision multi-cavity injection molding, the multi cavity injection molds is crucial for achieving quality-compliant precision plastic products. Multi cavity injection molds design directly impacts the quality of the plastic product. On the one hand, the rationality of the multi cavity injection molds design determines the plastic's fluidity within the mold cavity; on the other hand, the mold material and manufacturing process also influence the quality of the finished product. Since mold cavity dimensions are determined by the required dimensions of the plastic product plus the shrinkage of the material used, and shrinkage is often within a range recommended by plastic manufacturers or engineering plastics manuals, mold design must consider not only the cavity geometry but also its compatibility with the multi cavity injection molding material. This is influenced not only by the multi cavity injection molds' gate pattern, location, and distribution, but also by the crystal orientation (anisotropy) of the engineering plastic, the shape and size of the plastic product, and the distance and location from the gate.

The main factors affecting plastic shrinkage include thermal shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage, and elastic recovery. These factors are related to the multi-cavity injection molding and operating conditions of precision injection molded products. Therefore, designers must comprehensively consider all these factors when designing multi cavity injection molds to ensure final product quality.

3. Multi Cavity Injection Molding Process Parameters

From a solid state (powder or pellets) to a liquid state (melt) and finally back to a solid state (product), the multi-cavity injection molding process transforms plastic. Different polymers (thermoset or thermoplastic, crystalline or amorphous, reinforced or nonreinforced, etc.) show different polymer structures and rheological behavior during this process. The properties of the polymer during the multi cavity injection molding process are directly affected by the multi-cavity injection molding process parameters.

Temperature, flow, and density will all impact the plastic's fluidity and final physical characteristics under the combined impact of these disciplines. Designers so have to precisely manage characteristics including injection pressure, rate, and temperature to guarantee enough plastic filling of the mold cavity and reduce multi-cavity injection molding imperfections.

3.1 Injection Pressure and Rate

Precision multi-cavity injection molding often utilizes high-pressure or ultra-high-pressure injection to minimize mold shrinkage. This is because high pressure allows the melt to be injected into the multi cavity injection molds quickly, minimizing the risk of bubbles and defects. Furthermore, high-speed injection effectively improves filling uniformity, ensuring consistent product quality across all cavities.

3.2 Temperature Control

Control of the injection melt temperature and mold temperature is also a crucial factor in multi-cavity injection molding. Appropriate temperatures ensure the plastic's fluidity and processability during the injection molding process, resulting in a flawless finished product with a flawless appearance and internal structure.

4. Plastic Material Selection

Choosing the right plastic is quite important in multi-cavity injection molding. Different plastic materials have distinct rheological properties, crystallizing behaviors, and reinforcing filler levels—all of which have great influence on the multi cavity injection molding quality. The rheological properties of the plastic directly influence filling efficiency in the multi-cavity injection molding process. Plastics with great flowability can quickly fill the mold cavity under high-pressure injection, therefore reducing defects and bubbles. Furthermore affecting the physical characteristics of the final product, particularly in applications needing strong strength and heat resistance, is the crystallinity and orientation of the material.

5. Environmental Factors for Multi Cavity Injection Molding

Environmental factors including temperature and humidity can also affect multi cavity injection molding. In moist environments, plastic materials might absorb moisture, therefore affecting their multi-cavity injection molding quality and flowability. Therefore, environmental conditions must be controlled throughout the multi-cavity injection molding procedure to ensure top plastic performance.

6. Strategies for Improving Precision Multi-Cavity Injection Molding Quality

The design phase is especially important in multi cavity injection molds production since it guarantees that the mold design is logical and satisfies production needs. Designers should have broad multi cavity injection molding knowledge and thoroughly evaluate the above elements to maximize multi cavity injection molds structure and gateway design.

-Precisely control the multi-cavity injection molding process: During the multi cavity injection molding process, precise control is applied to process parameters such injection pressure, temperature and injection rate to guarantee appropriate plastic flow and fill inside the multi cavity injection molds. To guarantee a steady production process, advanced injection molding equipment and monitoring systems are utilized to dynamically change process variables.

-Chosen plastic material based on the product's desired use and known properties: Different uses could call for various kinds of plastic to guarantee the performance and quality of the finished product.

Multi cavity injection molds and molding equipment are frequently examined and serviced to guarantee they are in top operational state. Quickly spotting and addressing possible problems can greatly minimize manufacturing defects and boost product quality.