KINGREAL UNIVERSAL IND., LTD

Phone

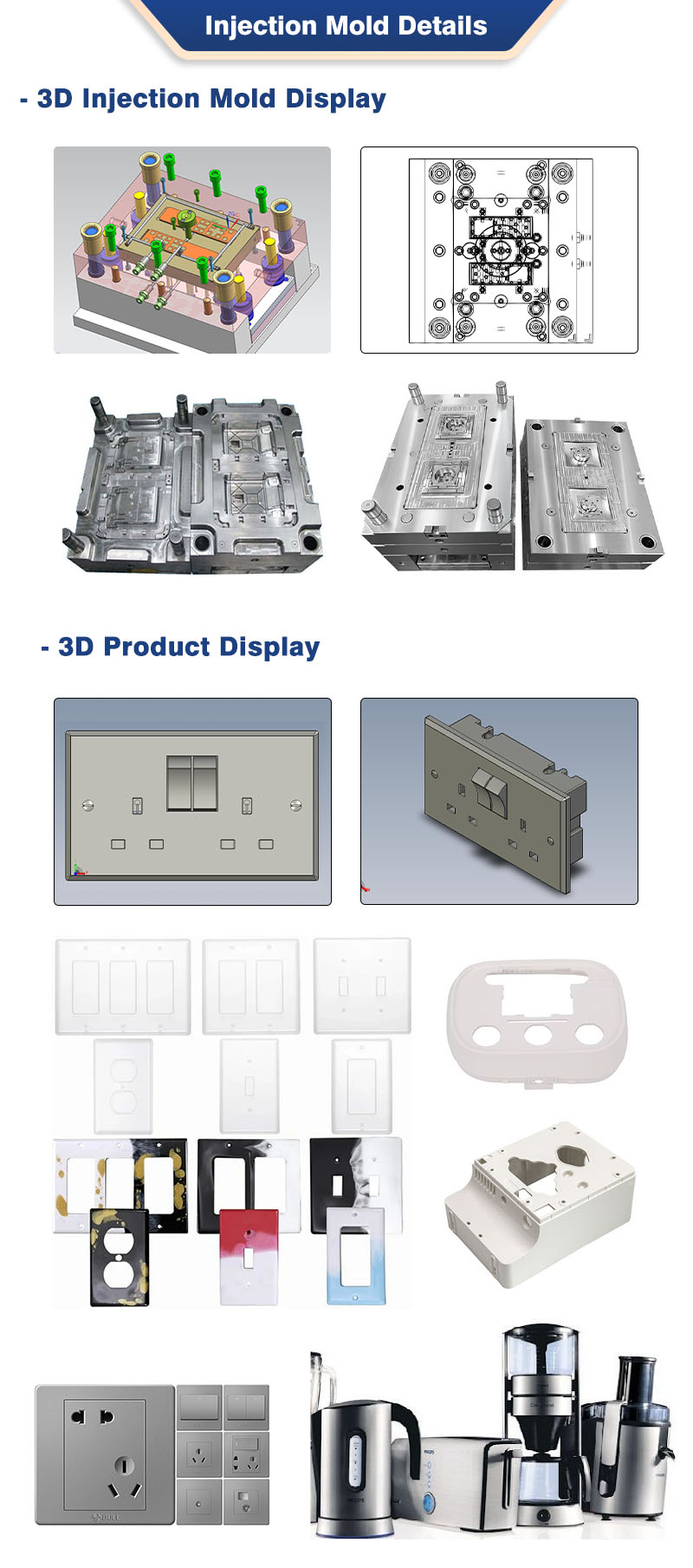

+86-13702855825| 1 | Classification of Small Appliance Housing Injection Molds |

| 2 | Application of Plastic Materials in Household Electrical Appliances Injection Molds |

| 3 | Design Principles for Household Electrical Appliances Injection Molds |

| 4 | Manufacturing Process for Household Electrical Appliances Injection Molds |

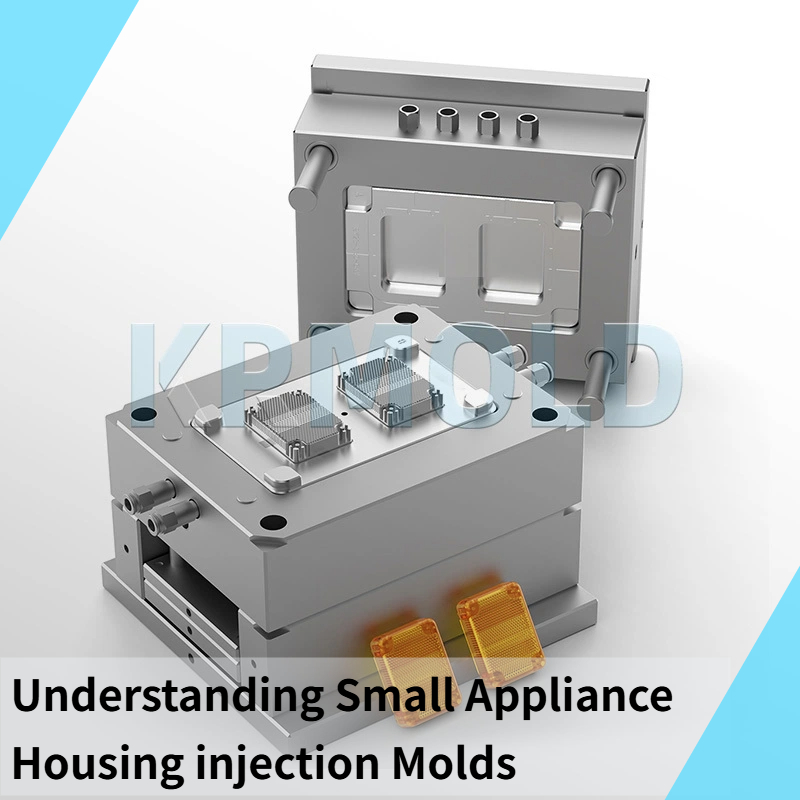

To ensure the quality and appearance of modern small and medium-sized household appliances, the design and manufacture of small appliance housing injection molds are crucial. This article will detail the classification, material applications, common plastic material selection, and their importance in the small appliance industry.

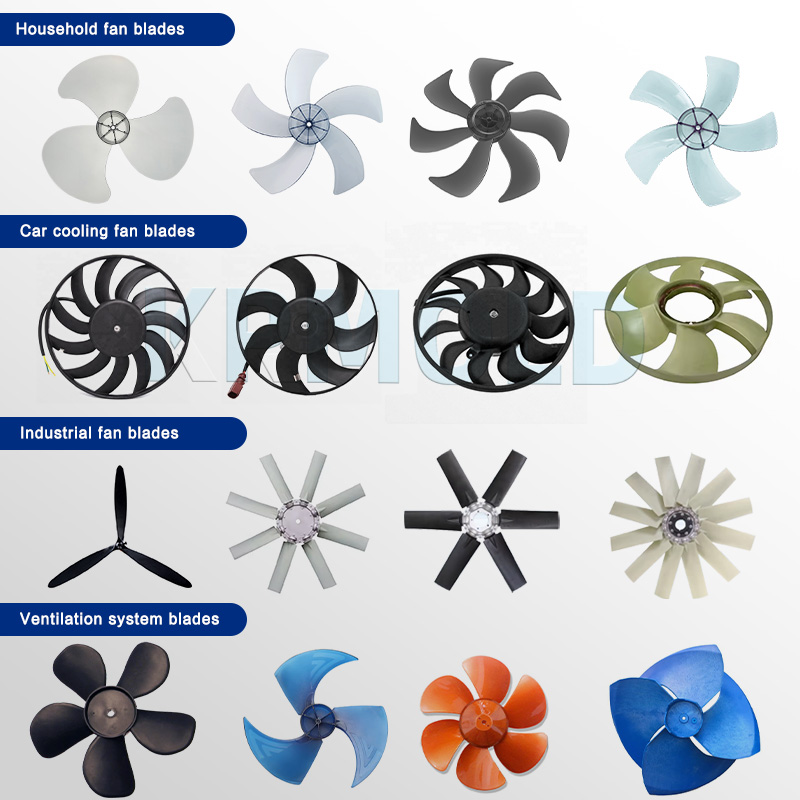

1.Classification of Small Appliance Housing Injection Molds

Many forms of small appliance housing injection molds exist. Common household electrical appliances injection molds can make housings for the following appliances: microwaves, rice cookers, electric irons, electric heaters, vacuum cleaners, electric fans. hair dryers, water dispensers, induction cookers, electric hot pots, electric kettles, air humidifiers, electric shavers, soymilk makers, juicers, and coffee machines. Every household electrical appliances injection mold has specific material choices and design demands that all affect the product's usefulness, look, and lifetime.

2.Application of Plastic Materials in Household Electrical Appliances Injection Molds

Choosing the correct plastic for the creation of small appliance housing injection molds has a direct influence on the product's appearance and also on its performance and service life. The following are the main plastic materials used in injection molded parts for various kinds of small appliance housings:

2.1 Main Materials for Exterior Parts

ABS (Acrylonitrile-Butadiene-Styrene): Offers high gloss and ease of painting, but has poor high-temperature resistance, making it suitable for lower-temperature equipment.

PP (Polypropylene): Low cost, good flowability, but poor dimensional stability, making it suitable for general small appliances.

PC (Polycarbonate): High strength, excellent heat resistance, and excellent transparency, but prone to cracking, making it suitable for products requiring transparent housings.

PC/ABS alloy: Offers excellent overall performance and strong impact resistance, but is relatively expensive, making it suitable for high-end small appliance housings.

2.2 Main Materials for Decorative Parts

Transparent materials, such as transparent ABS, PMMA (Polymethyl Methacrylate), and PC, are suitable for decorative parts that require light transmission.

Electroplating Materials: Electroplating-grade ABS is commonly used for parts requiring electroplating treatments on the exterior.

Film Materials: PET and PC films are commonly used for panels and protective layers.

2.3 Core Requirements for 3C Key Components

Flame-retardant materials, such as flame-retardant PBT, flame-retardant PP, and flame-retardant PPO, ensure the safety of appliances under high-temperature conditions and prevent fire hazards.

2.4 Core Requirements for Other Key Structural Components

High-performance materials, such as POM (polyoxymethylene), glass-fiber-reinforced nylon, PPS (polyphenylene sulfide), PPA (polyamide), and PEI (polyetherimide), are used for high-strength and heat-resistant components.

3. Design Principles for Household Electrical Appliances Injection Molds

3.1 Manufacturability

Manufacturability is the primary principle in the design of small appliance housing injection mold. Designers must ensure that all mold components can be smoothly manufactured and assembled. This includes comprehensive consideration of the household electrical appliances injection mold's shape, dimensions, and processing technology. Good manufacturability not only reduces production costs but also minimizes potential production issues.

Shape Design: The small appliance housing injection mold shape should be kept as simple as possible, avoiding complex geometries. This decreases the probability of error and processing complexity.

Dimensional Tolerance: Dimensional tolerances should be established during the design phase to guarantee that dimensional variations during manufacturing do not result in molding flaws.

Processing Technology: To guarantee household electrical appliances injection mold production quality and efficiency, choose a suitable processing technology such as CNC machining or EDM.

3.2 Molding Process

Good flow and filling performance during the injection molding process depend on the alignment of injection molding process parameters with the household electrical appliances injection mold design. Designers should take into account these elements:

Injection Temperature: Optimally adjust the injection temperature to guarantee easy plastic material flow during insertion into the small appliance housing injection mold, therefore preventing inadequate filling resulting from low temperatures.

Injection Pressure: Based on the household electrical appliances injection mold design and material properties, set the appropriate injection pressure to ensure rapid and accurate small appliance housing injection mold filling.

Cooling System: A properly designed cooling system ensures uniform cooling of the household electrical appliances injection mold after injection, preventing deformation or cracking caused by uneven cooling.

3.3 Strength and Rigidity

To avoid deformation that could cause molding, the household electrical appliances injection molding process must guarantee strength and rigidity. Designers ought to take these factors into account:

Material Selection: Make sure your small appliance housing injection molds made of strong and high-rigidity materials, such steel or aluminum alloy, do not warp during high-pressure injection molding.

Structural Design: A decent structural design can efficiently spread the tension produced during the injection molding process, thereby avoiding damage brought on by focused stress.

Reinforcement Design: Implement reinforcements at key locations, such as adding ribs or using special structures, to enhance the small appliance housing injection mold's overall strength and rigidity.

3.4 Repair and Maintenance

Design should account for small appliance housing injection mold maintenance and servicing to enable next cleaning, repair, and component replacement. Effective repair design can Reduce downtime and extend the life of the household electrical appliances injection mold; certain measures include:

Easy Disassembly: The household electrical appliances injection mold's structure should be designed for easy disassembly and assembly, ensuring quick maintenance.

Clear Labeling: Label each component on the small appliance housing injection mold with its name and number to facilitate quick identification and replacement by maintenance personnel.

Maintenance Manual: Provide a detailed maintenance manual that outlines regular inspection and maintenance items to ensure the mold remains in good working condition.

4. Manufacturing Process for Household Electrical Appliances Injection Molds

The manufacturing process for small appliance housing injection molds is relatively complex, but each step is crucial. The following are the main steps in the manufacturing process:

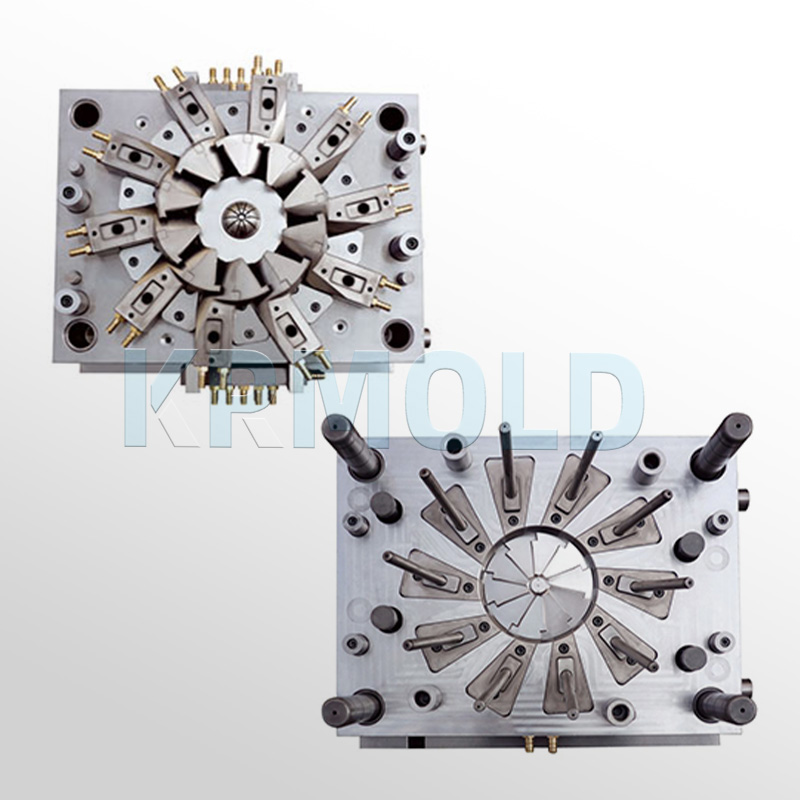

4.1 Design and modeling small appliance housing injection mold

The first step in household electrical appliances injection mold manufacturing is to design the small appliance housing injection mold using CAD software and create a 3D model. This stage requires consideration of the household electrical appliances injection mold's function and production requirements to ensure that the design meets actual production needs. After the design is completed, simulation analysis is typically performed to check the small appliance housing injection mold's performance during the injection molding process and ensure the design is reasonable.

4.2 Machining household electrical appliances injection mold

The household electrical appliances injection mold is machined according to the design drawings, including CNC machining and EDM machining. CNC machining ensures high-precision dimensions and shapes, while EDM machining is suitable for machining complex shapes. Ensuring small appliance housing injection mold accuracy and surface quality is key during this stage and directly impacts the subsequent injection molding results.

4.3 Assembly for small appliance housing injection mold

After machining is completed, the household electrical appliances injection mold components are assembled. Ensure that the components fit together properly to avoid household electrical appliances injection mold failure caused by improper assembly. Good assembly is essential for proper small appliance housing injection mold function.

4.4 Testing and debugging small appliance housing injection mold

To make sure the household electrical appliances injection mold fulfills design criteria and operates appropriately during the actual injection molding process, test and debug it. Testing guarantees the small appliance housing injection mold design and manufacture fulfill requirements by creating test pieces and examining the dimensions, look, and behavior of the molded pieces.

4.5 Production and maintenance for small appliance housing injection mold

Frequent maintenance and care are needed to guarantee its long-term usage once the small appliance housing injection mold is put into manufacturing. Maintenance work involves cleaning the inside of the household electrical appliances injection mold, checking the small appliance housing injection mold often for wear, and so on. changing delicate parts to guarantee the household electrical appliances injection molding stays in top shape.