KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Why are Plastic Washing Machine Injection Molds Important? |

| 2 | Parameters of Plastic Washing Machine Injection Mold |

| 3 | Plastic Washing Machine Injection Mold Design Considerations |

| 4 | Full Washing Machine Plastic Injection Mold Manufacturing Process |

| 5 | How to Maintain Washing Machine Plastic Injection Molds? |

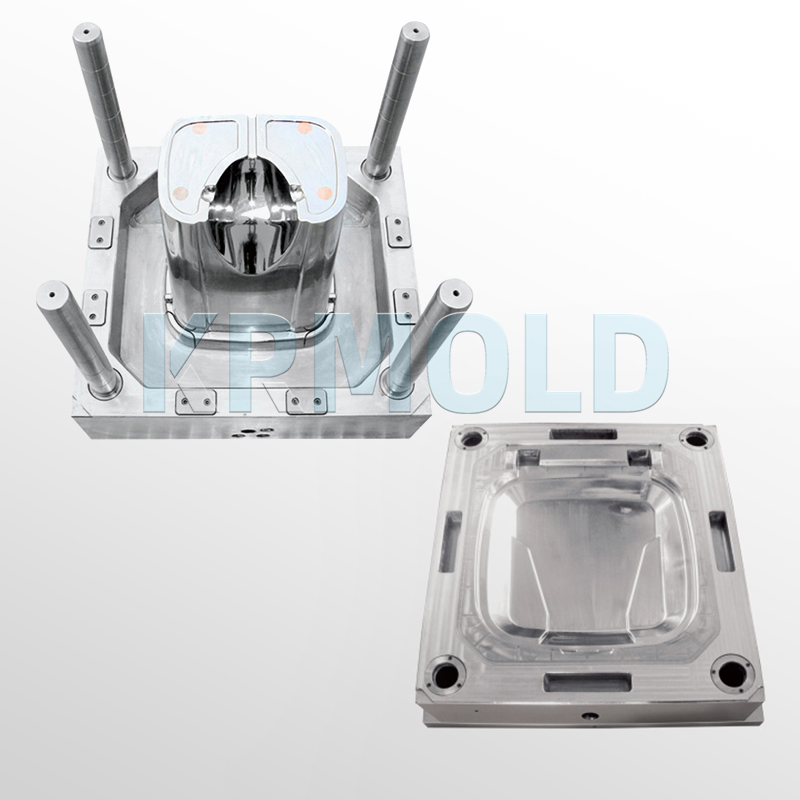

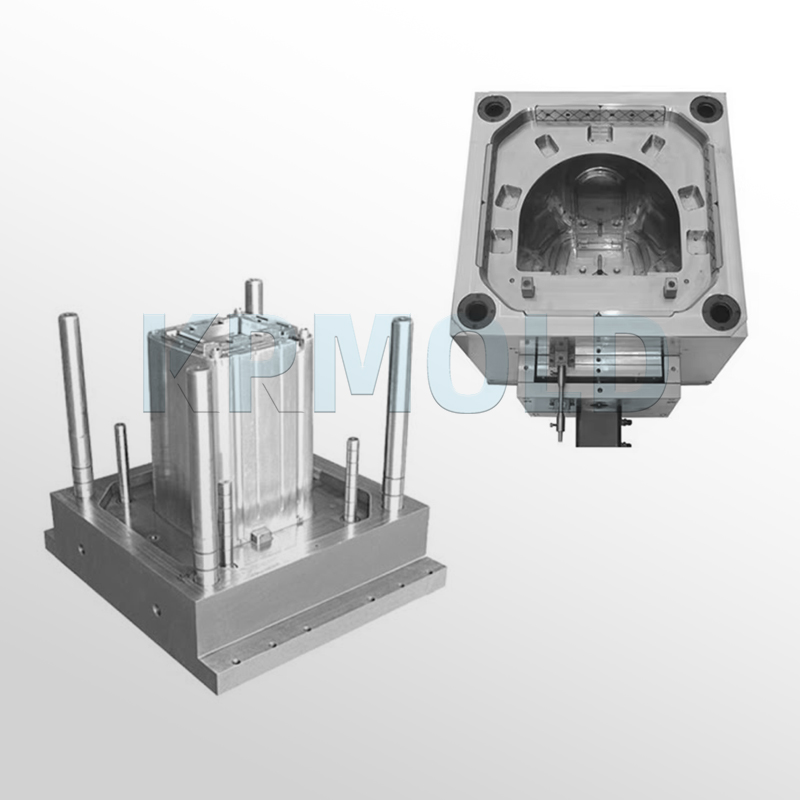

In modern home appliance manufacturing, washing machine plastic injection molds play a crucial role. As the foundation for the production of all washing machine components, plastic washing machine injection molds not only impact product functionality but also directly influence product aesthetics and market competitiveness. KRMOLD washing machine plastic injection molds are created in response of consumer demands and can make exact parts including outside casings, knobs, washing machine drums, Control panels and lids perfect for washing machines of different kinds and sizes. This essay will discuss the need of washing machine plastic injection molds, including design factors, material choices, production methods, and upkeep techniques.

1.Why are Plastic Washing Machine Injection Molds Important?

Making process depends on washing machine plastic injection molds as they are essential component. Necessary for the entire washing machine are the parts made by the plastic washing machine injection molds. Only good washing machine plastic injection molds can guarantee the manufacture of high-precision finished goods, therefore guaranteeing dimensional accuracy and fit for all internal parts.

The quality of the plastic washing machine injection molds utilized determines mostly the production efficiency of washing machines. High-quality washing machine plastic injection molds can greatly raise manufacturing efficiency and lower scrap rates. Manufacturers are hence more and more encouraged to invest in premium washing machine plastic injection molds to guarantee their products are both totally practical and visually appealing, thereby attracting consumer interest.

2.Parameters of Plastic Washing Machine Injection Mold

| Core and Cavity Steel | P20, 718H, 2738H, H13, NAK80, 2316, etc. |

| Mold Base and Standard Parts | DME, HASCO, Custom-Made, etc. |

| Steel Hardness | HRC 48-52 |

| Plastic Materials | PP, PC, PE, ABS, PVC, etc. |

| Number of Cavities | Single or as per your requirements |

| Injection System | Side Gate, Needle Gate |

| Ejector System | Ejector |

| Runner | Hot Runner, Cold Runner |

| Cycle Time | 30-120s |

| Mold Life | 500,000 Cycles |

| Quality Assurance | ISO9001 |

3.Plastic Washing Machine Injection Mold Design Considerations

(1)CAD design for plastic washing machine injection mold

Usually advanced computer-aided design (CAD) programs are needed to create a washing machine plastic injection mold. Designers need to take into account several elements throughout the design process including shrinking, cooling rate, and material flow to guarantee the final product satisfies demanding quality specifications. A well-designed plastic washing machine injection mold lowers defects and greatly raises manufacturing efficiency in addition to shortening production cycle time.

(2)Aesthetic design for washing machine plastic injection mold

Furthermore, product aesthetics should be taken into account when designing plastic washing machine injection molding. Direct influence on a washing machine plastic injection mold's market acceptability is its external design. Often drawn to its look when picking a washing machine, customers should be balanced in design by KRMOLD engineers between utility and beauty.

(3)Washing machine plastic injection mold material selection

The selection of mold material is crucial in the manufacture of washing machine plastic injection molds. Often employed materials with both advantages and drawbacks are steel and aluminum:

-Steel molds: They are ideal for high-volume manufacturing, can survive longer production cycles, and are robust. Their production cost, though, is rather expensive.

-Aluminum molds: They are lighter and easier to process, making them suitable for small-batch production or prototyping. Aluminum molds are less expensive, but their durability is lower than that of steel molds.

KRMOLD usually works with acrylonitrile butadiene styrene (ABS), polypropylene (PP), polycarbonate (PC), and polyethylene (PE) to create plastic components for washing machines. ABS is a commonly used material for washing machine external panels and control panels since it is impact-resistant and long-lasting. Lightweight and strong, polypropylene is appropriate for other inner parts as well as washing machine tubs. Though it is more difficult to process, polycarbonate's great strength and transparency render it fit for specific components. Given its flexibility and water resistance, polyethylene is sometimes employed in hoses and drain components.

Choosing the perfect material assures the strength, utility, and longevity of washing machine plastic parts, therefore enhancing the general performance of the appliance.

4.Full Washing Machine Plastic Injection Mold Manufacturing Process

Usually the manufacturing of plastic washing machine injection molds consists of several steps: design of the plastic washing machine injection mold, manufacture, assembly, testing. Precise machining methods employed during the manufacturing process produce the required voids and cores, hence ensuring suitable plastic molding.

Plastic washing machine injection mold design: Design is based on customer requirements and product characteristics, taking into account factors such as material flow, cooling, and shrinkage.

Plastic washing machine injection mold manufacturing: Advanced technologies such as CNC machining are used to create the mold cavity and core that meet the design requirements.

Assembly: The individual components are assembled into a complete plastic washing machine injection mold to ensure proper function.

Testing: The assembled washing machine plastic injection mold undergoes rigorous testing to ensure that its performance and the resulting parts meet quality standards.

KRMOLD may create superior plastic washing machine injection molds via this series of operations to satisfy the many demands of KRMOLD customers.

5.How to Maintain Washing Machine Plastic Injection Molds?

Long-term operation and performance of plastic washing machine injection molds depend on good maintenance. Key maintenance measures follow:

Regular Cleaning: To get rid of plastic trash, filth, or other material that could compromise standard display, the plastic washing machine injection mold should be cleaned on a regular basis. Regular cleaning guarantees efficient mold operation and helps to avoid errors in molding additions.

Lubrication: Applying a suitable lubricant to every moving element of the plastic washing machine injection mold lowers friction, boosts performance, and helps to stop corrosion. Important stage in mold maintenance, lubrication lengthens its life span.

Regular Inspection: Look for rips or damage on the plastic washing machine injection mold frequently. Quickly identifying and fixing any problems helps to prevent expensive repairs.

Proper Storage: To prevent damage and corrosion, washing machine plastic injection molds should be stored in a dry, smooth atmosphere. For the long-term usage of the plastic washing machine injection mold, appropriate storage conditions are vital.

Record maintenance history: Record every maintenance and inspection to help you track the plastic washing machine injection mold's usage level and to enable prompt modifications and upgrades.