KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Introduction to Electronic Component Injection Molds |

| 2 | Advantages of Electronics Plastic Injection Molds |

| 3 | Applications of Electronic Component Injection Mold |

| 4 | Common Materials for Electronics Plastic Injection Molds |

Essential for the production of consumer electronics are electronic component injection molds. They assist clients in rapidly creating injection-molded electronic parts meeting the industry's demanding requirements for a broad range of uses. KRMOLD can create the necessary electronic component injection molds to satisfy the requirements of their projects despite any hurdles KRMOLD customers may face for the needed electronic components. Meeting the requirements of high-volume production of intricate components, these electronics plastic injection molds combine accuracy, cost-effectiveness, and durability. Electronics plastic injection molding can be enlarged to satisfy any electronics maker's need for excellent structural components, intricate functional parts, and almost any other plastic item.

1/Introduction to Electronic Component Injection Molds

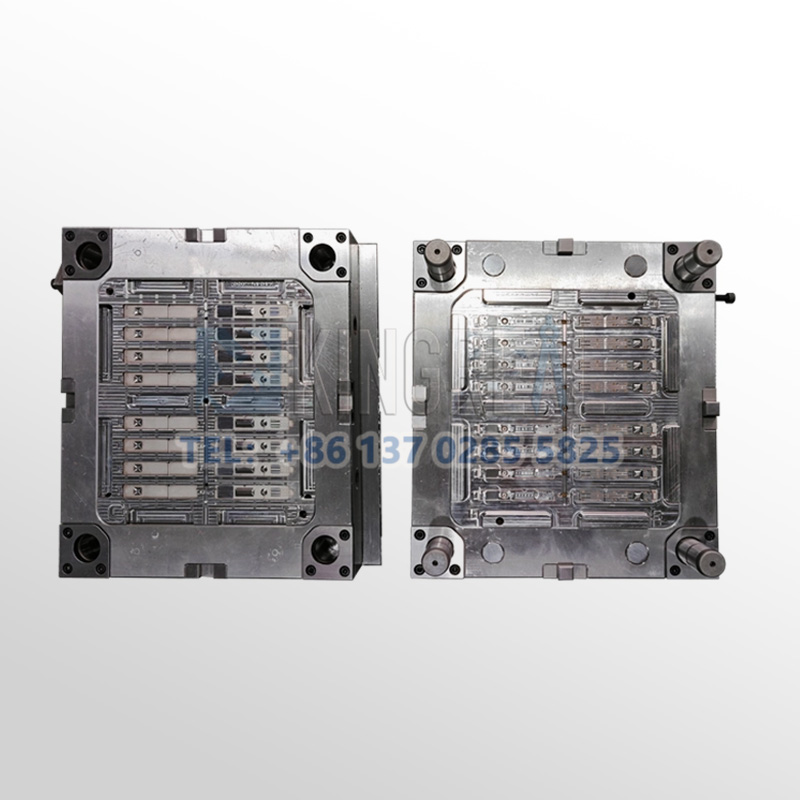

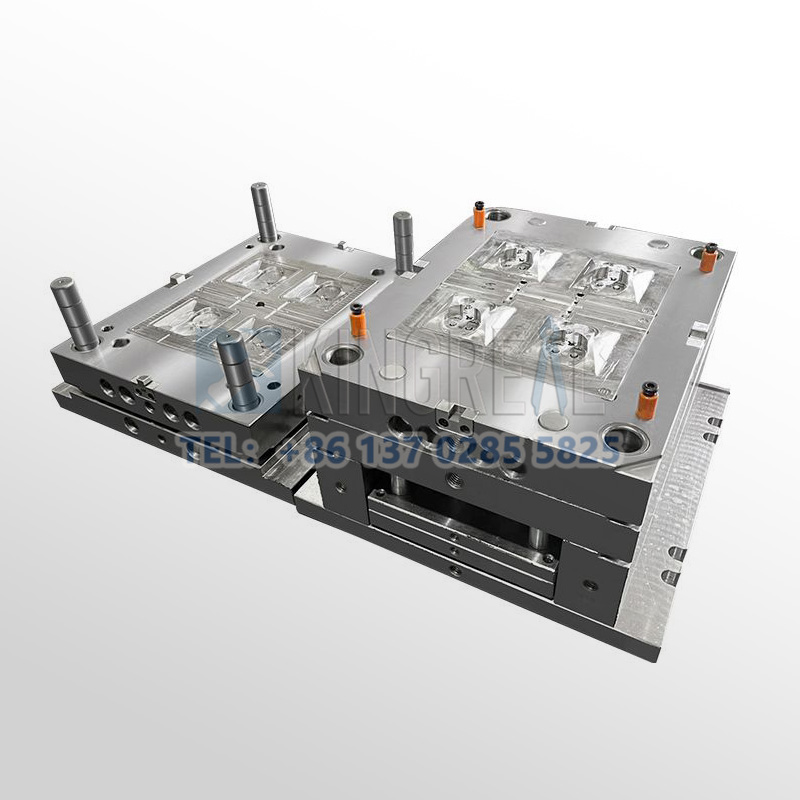

Manufacture of structural and functional components in electronic devices calls for electronics plastic injection molding. Injection molding provides a dependable and scalable solution from casings protecting sensitive components to internal parts providing connectivity and performance. Its accuracy makes it a perfect fit for electronic devices, where components have to be exactly aligned to guarantee performance and durability. Electronic component injection molds allow producers to satisfy demand while preserving quality by producing many consumer electronic parts.

The design and production of electronic component injection molds include a few important processes: mold design, material choice, production techniques, and post-production quality inspection. Electronics plastic injection molds can greatly minimize material waste and boost manufacturing efficiency throughout the production process by means of careful design and precise computation. In the electronics sector, where product quality and delivery time are under very great expectations, this is especially crucial.

2/Advantages of Electronics Plastic Injection Molds

1) High-volume production for electronic component injection mold

Electronics plastic injection molding technology enables efficient large-scale production. By injecting large quantities of plastic at once, manufacturers can produce thousands of parts in a short period of time. This manufacturing approach not only greatly speeds up delivery cycles but also considerably raises manufacturing effectiveness. Moreover, electronics plastic injection molds provide great consistency throughout the manufacturing process, so producers may guarantee the quality and performance of every component. stringent standards help to cut losses brought on by quality problems and lessen rework.

2) Design flexibility for electronic component injection mold

From simple housings to complex internal structures, electronics plastic injection molding can meet a variety of design requirements. By using different electronics plastic injection mold designs and molding technologies, manufacturers can achieve more complex geometries and meet the diverse and personalized needs of product designs.

3) Material diversity for electronic component injection mold

To satisfy several product needs, electronics plastic injection molds enable the use of a range of materials including polycarbonate, ABS, and nylon. Every material has distinct performance properties, and based on the particular application, manufacturers can select the best material. Material diversity not only allows goods to work in several settings but also satisfies particular needs of many consumers, hence increasing their market competitiveness.

4) Precision and accuracy for electronic component injection mold

High-tolerance components—which are essential for building the complicated interior components of electronic devices—electronics plastic injection molds can produce throughout the manufacturing process. This accuracy guarantees a great fit for every component, therefore lowering product failure rates. Electronic component injection molds provide consumers with dependable goods by means of cutting-edge molding techniques and strict quality control process that keeps a high degree of manufacturing precision.

5) Durability for electronic component injection mold

Electronics plastic injection molding guarantees the endurance of parts like connectors, housings, and circuit boards, therefore enabling long-term application. High-quality materials and sophisticated production techniques help manufacturers to properly lengthen molded component life. Some electronic devices, for instance, need to be used in severe surroundings including high temperature, high humidity, or corrosive situations. Durable electronic component injection molds guarantee great performance under these situations. This sturdiness increases consumer happiness and lowers maintenance expenses.

6) Consistency for electronics plastic injection mold

Large-scale manufacture benefits especially from injection molds since they guarantee every part satisfies exact requirements. The great repeatability of electronics plastic injection molding lets producers keep constant product quality from batch to batch, so boosting customer trust. Strict quality control systems and ongoing process improvement help producers to guarantee a high degree of consistency throughout the manufacturing cycle.

3/Applications of Electronic Component Injection Mold

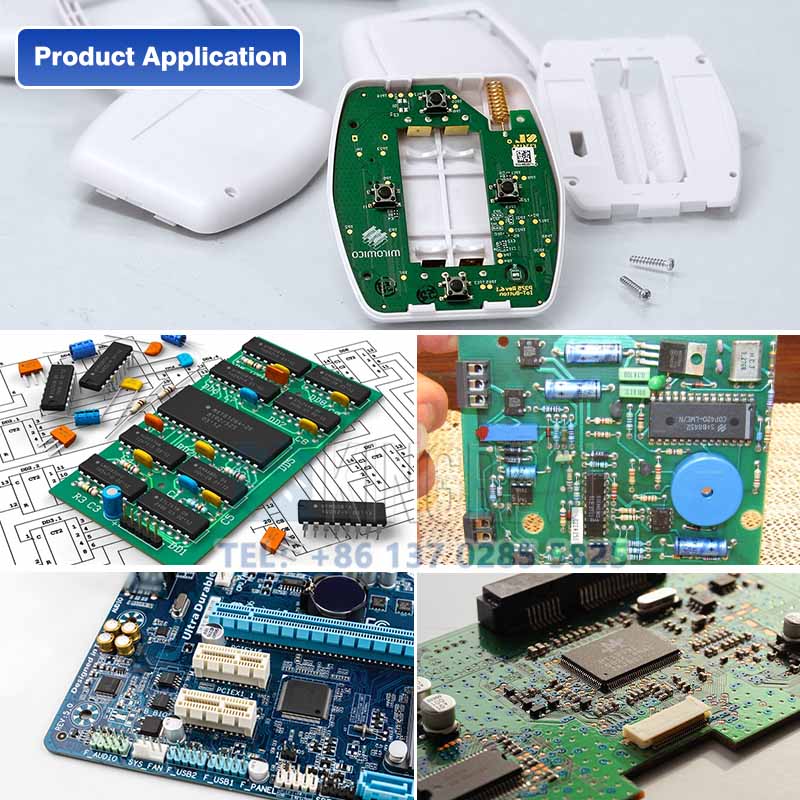

-Housings and Enclosures: Electronics plastic injection molding is used to produce housings and enclosures that protect sensitive electronic components such as relays, sensors, switches, and buttons. These enclosures must not only provide excellent protection but also meet aesthetic and functional requirements.

-Electronic Connectors: Electronic connectors are essential for establishing connections between electronic circuits. These components can be produced using injection molding, overmolding, and insert molding, ensuring their reliability in various environments.

-Instruments, Sensors, and Other Test Equipment: Instruments, sensors, and industrial test equipment are essential to the electronics industry. Various injection molding techniques, such as overmolding and insert molding, can help achieve the tight tolerances required for these components, ensuring their accuracy in real-world applications.

-Telecommunications Components: Injection molding can create complex shapes with precision and consistency, making it ideal for producing telecommunications components such as electrical insulation covers, housings, buttons, connectors, mounting brackets, routers, switches, and more. With the rapid growth of the telecommunications industry, the demand for high-performance components is increasing.

-Semiconductor Processing Equipment: Plastic injection molding enables the production of semiconductor components and devices to tight tolerances and high dimensional accuracy, which is critical to ensuring the performance of electronic products.

4/Common Materials for Electronics Plastic Injection Molds

Common materials used for electronic component injection molds include:

-Polycarbonate: As a strong and durable material, polycarbonate is often used in the production of housings and lenses, providing excellent protection.

-ABS: ABS is known for its excellent impact resistance and is commonly used to manufacture a variety of durable structural components suitable for a wide range of electronic products.

-Nylon: Nylon is a material suitable for connectors and components requiring flexibility, offering good wear and chemical resistance.

PEEK: PEEK is well-suited to high temperatures and harsh environments, maintaining excellent performance under extreme conditions and is widely used in high-end electronic devices.