KINGREAL UNIVERSAL IND., LTD

Phone

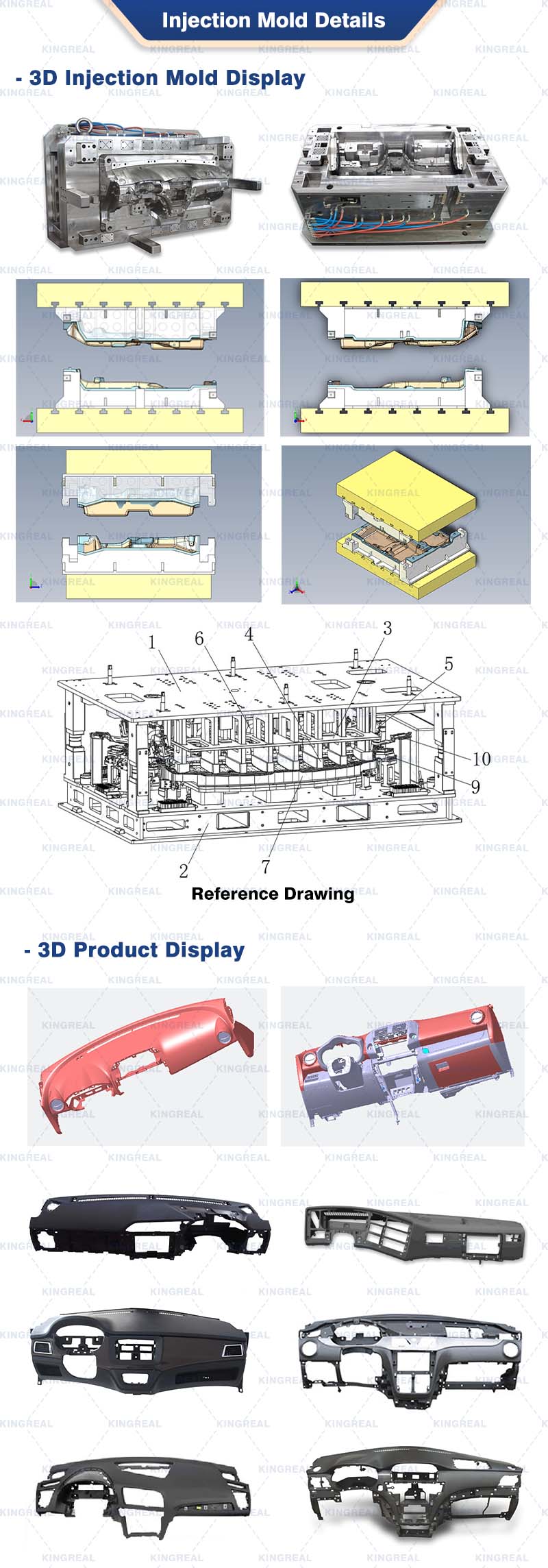

+86-13702855825| 1 | Features of KRMOLD Automotive Control Panel Injection Mould |

| 2 | Components of Automotive Control Panel Injection Mould |

| 3 | Features of Automotive Control Panel Injection Mould |

| 4 | Automotive Control Panel Production Process |

| 5 | Key Considerations for Car Dashboard Injection Mold |

| 6 | Design Considerations for Car Dashboard Injection Mold Structure |

Automotive control panel injection mould are an indispensable component of modern automobile manufacturing. KRMOLD, a renowned manufacturer of car dashboard injection molds, is committed to providing customers with high-quality, customized automotive control panel injection mould solutions to meet the needs of well-known domestic and international automotive brands.

1.Features of KRMOLD Automotive Control Panel Injection Mould

KRMOLD car dashboard injection molds adopt Mold-tech textures and DME standards. These international standards ensure consistency and high quality in automotive control panel injection mould design and manufacturing. KRMOLD car dashboard injection molds not only meet stringent industry standards but can also be tailored to specific customer needs, ensuring optimal performance and functionality for each automotive control panel injection mould. Car dashboard injection mold dimensions can be customized according to customer requirements, with a maximum length typically of 1200mm, fully meeting the needs of different vehicle models and designs. During the automotive control panel injection mould design process, KRMOLD engineers fully consider cost-saving factors, especially in runner design. A reasonable runner size not only reduces material usage but also accelerates gate solidification and reduces pressure loss. Furthermore, the size of the manifold should be combined with the cavity volume and the wall thickness of the molded part to ensure efficient car dashboard injection mold operation during injection molding. KRMOLD is a professional automotive control panel injection mould manufacturing company with extensive experience, specializing in the production of high-quality car dashboard injection molds. KRMOLD provide our customers with reasonable quotes, superior product quality, and excellent after-sales service, thus winning the trust and support of clients both domestically and internationally. |  |

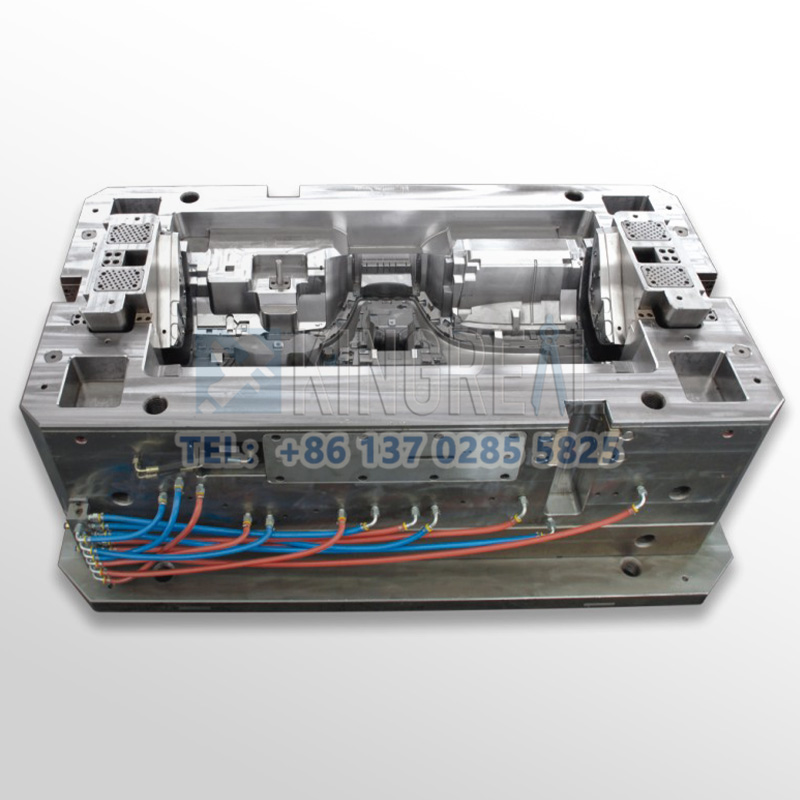

2.Components of Automotive Control Panel Injection Mould

Car dashboard injection molds mainly consist of the following parts:

-Injection Mold: Includes the cavity and core. The cavity is formed between the core and the insert, used for injection molding the automotive dashboard.

-Mold Cover: Covers the mold and protects the cavity, ensuring it is not contaminated during the injection molding process.

-Injection Gate: Located on the mold cover, it injects molten plastic, ensuring smooth flow of the plastic into the cavity.

-Clamping Rails and Clamping Slides: Used to clamp the mold cover, ensuring the mold's seal during injection molding and preventing molten plastic leakage.

-Screw and Vertical Shaft: Drives the clamping slides, enabling the car dashboard injection mold to open and close, ensuring smooth operation during injection molding and demolding.

3.Features of Automotive Control Panel Injection Mould

3.1 Impact resistance for car dashboard injection mold Meeting the demanding requirements of modern automakers, the automotive control panel injection mould is painstakingly created employing sophisticated CAD/CAM technology. High-precision, very uniform automotive panels results from it guarantee great installation.

3.2 High temperature resistance for car dashboard injection mold Car dashboards produced by the automotive control panel injection mould effectively withstand the high temperatures inside the vehicle, maintaining stable physical properties even under high-temperature conditions.

3.3 Wear resistance for car dashboard injection mold Constructed of superior steel, the automotive control panel injection mould can survive severe conditions and keep its integrity over long lifetimes, therefore providing long-term reliability and cutting maintenance expenses. Particularly crucial for regularly used vehicle control panels. |  |

4.Automotive Control Panel Production Process

-Mold Closure: Close the car dashboard injection mold to ensure it is in place, ready for injection molding.

-Feeding: Add dried plastic granules to the hopper of the injection molding machine, ensuring the quality of the plastic material.

-Melting: Heat the injection molding machine to melt the plastic granules, forming injectable molten plastic.

-Injection: Inject the molten plastic into the automotive control panel injection mould using the injection unit, ensuring the mold cavity is completely filled.

-Holding pressure: Maintaining a certain pressure within the car dashboard injection mold ensures the plastic completely fills the mold, preventing air bubbles or defects.

-Cooling: Cooling and solidifying within the car dashboard injection mold to form the plastic product, ensuring its shape and dimensional stability.

-Demolding: Opening the car dashboard injection mold, removing the plastic product, and completing the production process.

5.Key Considerations for Car Dashboard Injection Mold

5.1 Material selection for car dashboard injection mold Selecting the right substance guarantees product performance, safety, and lifespan. Commonly employed materials with great processing performance and outstanding physical characteristics—hence fit for automotive control panel manufacturing—include PP, PC/ABS, and ABS.

5.2 Design considerations for car dashboard injection mold When designing the automotive control panel injection mould, the rigidity, energy absorption, and aesthetics of the automotive control panel must be considered, while avoiding stress concentration. For example, using rounded corners can effectively reduce stress concentration, thereby extending the lifespan of the automotive control panel injection mould and the product.

5.3 Process control for car dashboard injection mold Product quality and manufacturing efficiency are much influenced by the selection and control of the injection molding procedure. Different production requirements can be satisfied with technologies like insert molding and gas- assisted injection molding. These procedures guarantee product quality while boosting production efficiency. |  |

6.Design Considerations for Car Dashboard Injection Mold Structure

When designing automotive control panel injection mould, several key design considerations should be taken into account:

6.1 Parting surface design for car dashboard injection mold

The parting surface is crucial in automotive control panel injection mould design as it determines the mold opening direction and demolding method. The parting surface design should be as simple as possible to reduce automotive control panel injection mould complexity and manufacturing costs, thereby improving production efficiency.

6.2 Cooling system design for car dashboard injection mold

Uniform cooling of the automotive control panel injection mould during injection molding results from a well-designed cooling system, therefore enhancing product quality and manufacturing efficiency. The form and size of the car dashboard injection mold must be taken into account during the design to guarantee consistent coolant flow.

6.3 Side core-pulling mechanism design for car dashboard injection mold

Automotive control panels typically have multiple side concave and convex structures, requiring complex side core-pulling mechanisms. The design of these mechanisms should consider material flowability and automotive control panel injection mould manufacturing processes to ensure product molding quality.

6.4 Gating system design for car dashboard injection mold

Automotive control panel injection mould typically employ hot runner gating systems to ensure uniform melt distribution within the car dashboard injection mold cavity and reduce weld lines. A well-designed gating system not only improves production efficiency but also enhances the product's appearance quality.

As a professional automotive control panel injection mould manufacturer, KRMOLD leverages its extensive experience and advanced technology to provide customers with high-quality, customized car dashboard injection mold solutions. Through rational design, superior material selection, and rigorous process control, KRMOLD automotive control panel injection mould meet customers' high requirements for product quality and performance.

For more information about automotive control panel injection mould, please contact KRMOLD.