KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Basic Concepts of Small Appliance Housing Injection Molds |

| 2 | Material Selection and Applications for Small Appliance Injection Molds |

| 3 | Current Application of Plastic Materials in Small Appliances |

| 4 | Processing Considerations for Small Appliance Injection Molds |

| 5 | Future Development of Small Appliance Injection Molds |

Technological developments have helped small household appliances become used daily more and more.

Practically all devices include electric heaters, microwave ovens, rice cookers, electric irons, vacuum cleaners, and electric fans.

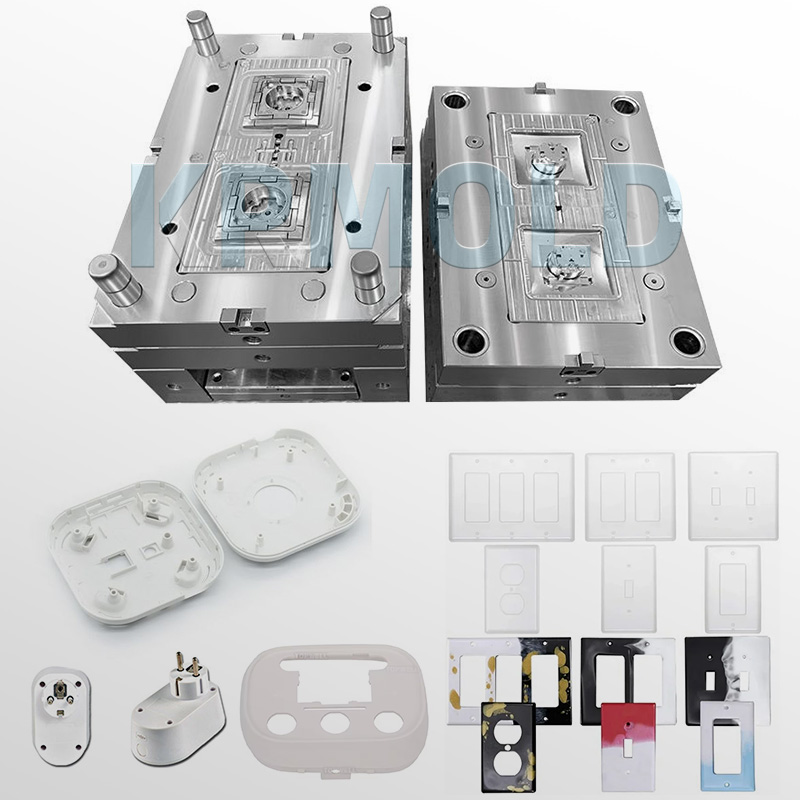

Mostly made with small appliance housing injection molds, the housings and structural elements of these small appliances rely mostly on them. This procedure depends critically on small appliance injection molds.

1. Basic Concepts of Small Appliance Housing Injection Molds

Manufacturing plastic components requires small appliance housing injection molds. The plastic is heated to a molten state, inserted into the small appliance injection mold, then cooled to generate the small appliance injection mold.The design and production of small appliance housing injection mold directly affect the product's appearance, performance, and manufacturing effectiveness.

For manufacturers, then, knowing how small appliance injection molds are used in tiny appliance housings is vital.

2. Material Selection and Applications for Small Appliance Injection Molds

The design requirements for small appliance housings typically include heat resistance, rigidity, and aesthetically pleasing appearance, and these requirements are particularly pronounced across different appliance products.

The following are some commonsmall appliance housing injection moldmaterials and their applications for small appliances:

(1) Microwave Ovens

Microwave ovens' plastic components mostly consist of handles, base, housing, and knobs.These parts need great heat resistance; hence popular plastic materials comprise PC/ABS, heat-resistant ABS, and PBT/PET+GF.These materials provide great moldability and processability in addition to satisfying heat resistance criteria.

(2) Rice Cooker

Heat-resistant ABS and high-gloss PP usually make up the exterior elements of rice cookers, including the housing, base, and lid.These materials guarantee the safety and stability of the product throughout use by providing great heat resistance and aesthetics.

(3) Electric Iron

High heat resistance and impact strength are required for plastic parts in electric irons. While PC and PA+GF—which offer higher heat resistance—are often utilized for the housing, handles, and sink base; ABS and high-gloss PP are often used for these.These decisions guarantee secure utilization in high-temperature situations.

(4) Vacuum Cleaner

To avoid dust absorption, vacuum cleaner casings and components need anti-static qualities. ABS, HIPS, and high-gloss PP are among often used materials, while PC and AS produce clear parts.These supplies provide great stiffness and impact resistance in addition to satisfying anti-static needs.

(5) Electric Fans

ABS, HIPS, and high-gloss PP are often used to produce plastic elements in electric fans including blades, blade covers, and housings. Among the benefits of these materials are great appearance and durability, simple molding, and good flowability.

(6) Water Dispensers and Other Small Appliances

Usually composed of ABS and HIPS, plastic parts in water dispensers need great stiffness, high gloss, and impact resistance. The housings of appliances like electric kettles and air humidifiers also often utilize heat-resistant ABS and high-gloss PP. These choices ensure the safety and durability of small appliances during use.

3. Current Application of Plastic Materials in Small Appliances

The selection of plastic materials is crucial in the design and manufacture of small appliances. The following are the characteristics and applications of some common materials:

ABS: High gloss, easy to paint, suitable for exterior parts, but relatively low temperature resistance.

PP: Low cost, good flowability, but poor dimensional stability, suitable for some structural parts.

PC: High strength, good temperature resistance, and excellent transparency, but prone to cracking, suitable for parts requiring transparency.

PC/ABS alloy: Offers excellent overall performance, but is more expensive, making it suitable for products with higher requirements.

For decorative parts, transparent materials such as transparent ABS, PMMA, and PC are commonly used. Electroplated and film-coated materials are also widely used in the design of small home appliances.

4. Processing Considerations for Small Appliance Injection Molds

When manufacturing small appliance housing injection molds, there are several key factors to consider:

(1) Product design requirements about small appliance injection mold

When designing small home appliance housings, it is important to clearly define requirements such as size, shape, and structure. These design requirements will directly impact small appliance housing injection mold manufacturing and use.

(2) Material selection about small appliance injection mold

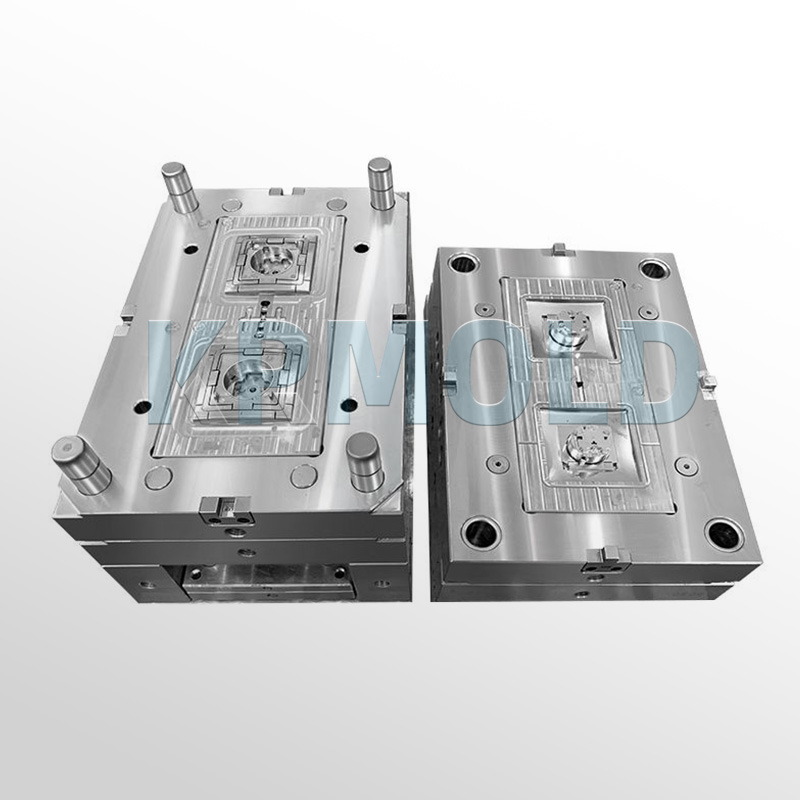

Select the appropriate mold material based on the material requirements for the small home appliance housing. Common small appliance housing injection mold materials include steel and aluminum alloy. Different materials have different properties and wear resistance, so the selection should be tailored to the specific situation.

(3) Manufacturing process

When selecting a manufacturing process, injection molding is the most common method. Thorough communication with the small appliance injection mold manufacturer is crucial to ensure that the small appliance housing injection mold can meet the product's manufacturing requirements.

(4) Quality of small appliance injection mold

Choosing high-quality small appliance housing injection molds is crucial, as mold quality directly impacts product molding quality and production efficiency. Understand the small appliance injection mold manufacturer's reputation and technical expertise, and refer to their past cases and customer reviews to ensure you choose a reliable supplier.

(5) Considering long-term partnership of small appliance injection mold

If you plan to use the small appliance housing injection mold for long-term production, it's recommended to choose a small appliance housing injection mold manufacturer with stable supply and after-sales service. This ensures timely support when maintenance, repairs, or mold replacements are needed.

(6) Cost control of small appliance injection mold

It's essential to balance product quality and cost. Try to choose small appliance injection molds with the best price-performance ratio, taking into account factors such as mold price, lifespan, and maintenance costs.

5. Future Development of Small Appliance Injection Molds

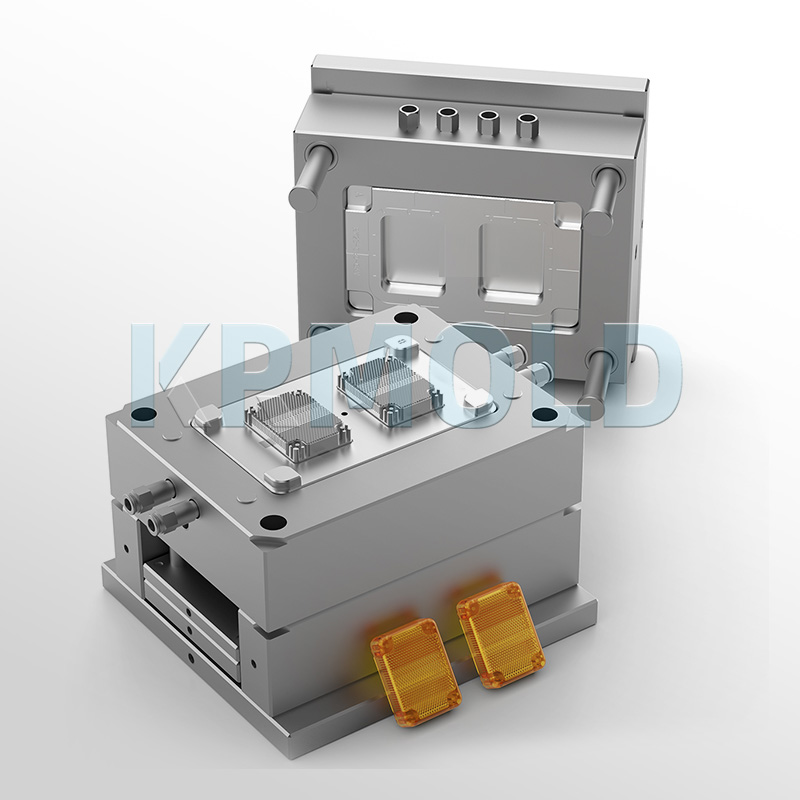

With the continuous advancement of technology, the technology behind small appliance housing injection molds is also evolving. In the future, small appliance injection molds will place greater emphasis on personalized design.

As consumer demand for personalized products increases, the design of small appliance housings will become more diverse. Small appliance housing injection molds will need to offer greater flexibility to meet market demand for personalized and customized products.