KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Parameters of Automotive Door Panel Mold |

| 2 | Manufacturing Process of Car Door Panel Injection Mold |

| 3 | Key Design Considerations for Automotive Door Panel Mold |

| 4 | Core Car Door Panel Injection Mold Manufacturing Technologies |

| 5 | Applications for Automotive Door Panel Mold |

Car door panel injection molds are essential equipment for producing precision door panels of varying specifications. Door panels not only offer useful protection and sealing but also greatly affect the outer design of a car as important parts of its interior and outside. The manufacturing quality and design of these automotive door panel molds are directly related to the accuracy of the product, the efficiency of production, and the general quality of the car in modern automotive manufacturing. This article will delve into the design principles, manufacturing technologies, application scenarios, and future trends of car door panel injection molds, providing industry professionals with a comprehensive understanding.

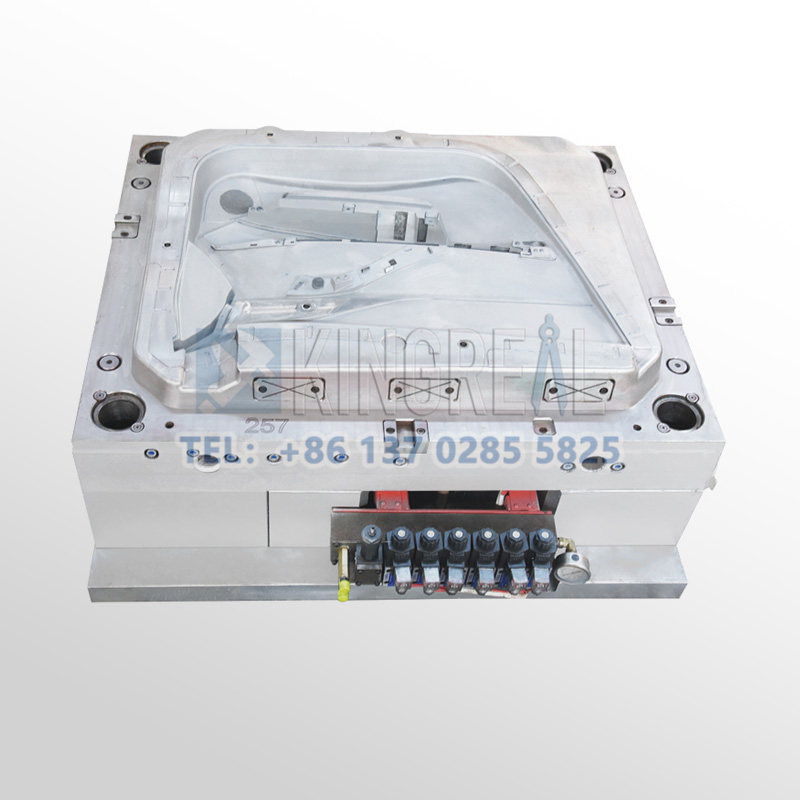

1.Parameters of Automotive Door Panel Mold

Surface Finish: Polishing

Mold Cavity: Single Cavity

Plastic Material: PE

Application: Car

Runner: Hot Runner

Installation: Fixed

Mold Steel for Core: HP20, H718, 2738

Mold Steel for Base: S50c

Mold Treatment: Nitridation, Quencher, Heat-Treated, Pre-Hardening

Mold Tooling Precision: 5-Axis Tooling Machine

Mold Cycle Time: 160s

Mold Life: More Than 500K Shoots

2.Manufacturing Process of Car Door Panel Injection Mold

The manufacturing process for the automotive door panel mold involves multiple processing stages, each with its own unique technical highlights to ensure high car door panel injection mold precision and quality.

2.1 Cavity machining for automotive door panel mold

With a contour accuracy requirement of ±0.02 mm, cavity machining is accomplished with a 5-axis high-speed machining center (20,000 rpm). The shape and measurements of the car door panel injection mold are guaranteed by this high-precision machining process to satisfy design requirements and to meet the demanding expectations of vehicle manufacturing.

2.2 Electrode manufacturing for automotive door panel mold

Electrodes are typically manufactured using graphite electro-spark engraving technology, achieving a surface finish of Ra 0.4μm. This meticulous surface treatment ensures smooth car door panel injection mold release during the injection molding process and reduces sticking.

2.3 Surface treatment for automotive door panel mold

The ultimate surface treatment is a mirror polish (15000 grit) with a gloss of ≥95GU. Besides improving the car door panel injection mold's aesthetics, this finish improves its corrosion resistance and durability.

3.Key Design Considerations for Automotive Door Panel Mold

When designing a car door panel injection mold, several key factors must be considered to ensure the automotive door panel mold's functionality and structural integrity.

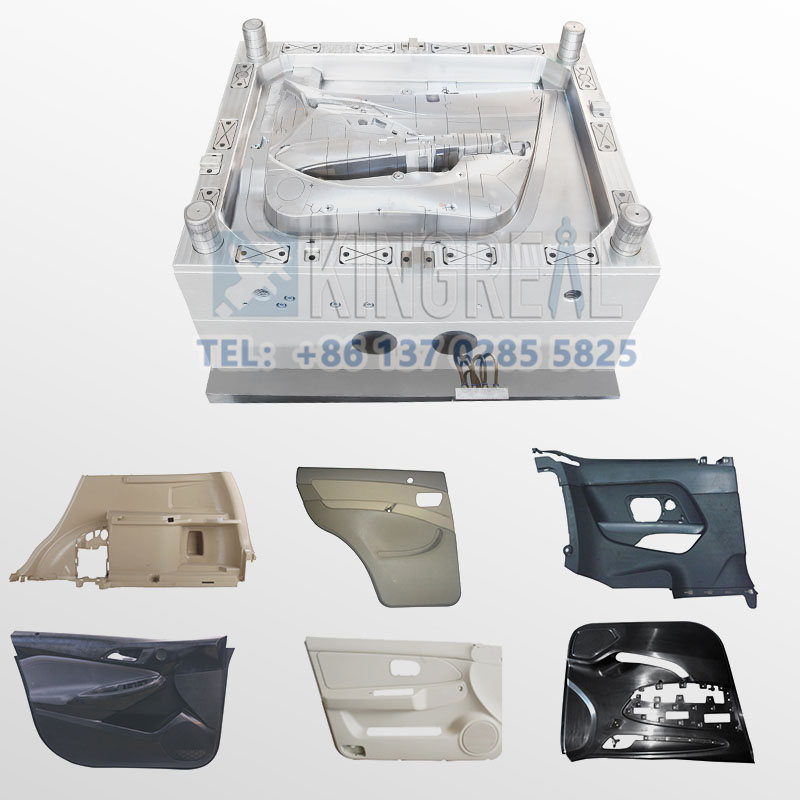

3.1 Structural design and functional integration

The design of modern car door panel injection molds requires a holistic approach, striking a balance between structural integrity (e.g., inner and outer panels, reinforcement ribs) and functional integration (e.g., speaker grilles, storage compartments, and electronic module slots). For example, high-end models often feature touch controls or ambient lighting, requiring designers to precisely plan the spatial layout during the automotive door panel mold design phase. CAD/CAE software allows designers to perform 3D modeling and simulation to optimize the alignment of the mold cavity with the product geometry.

3.2 Material selection and process optimization

Mold material selection is crucial to car door panel injection mold performance. Common mold materials are pre-hardened steels like P20 and 718H (hardness 30–40 HRC) for improved wear resistance. Aluminum alloys with nitrided surfaces are becoming increasingly popular in line with the lightweighting trend. Injection molding is still prevalent, but polymers need specific modifications in characteristics like automotive door panel mold temperature (controlled to ±1°C for high-gloss, unpainted materials). such as PP, ABS, or PC/ABS mixes to prevent surface flaws.

3.3 Ejector and cooling system design for car door panel injection mold

Complex ejector systems (such as lifters, slides, and hydraulic cylinders) are crucial for demolding complex geometries.

4.Core Car Door Panel Injection Mold Manufacturing Technologies

4.1 High-precision machining for automotive door panel mold

Mold cavity tolerances must be maintained within ±0.02 mm. Five-axis CNC machines can perform roughing and semi-finishing, while critical surfaces require wire EDM (accuracy ±0.005 mm) and mirror EDM (roughness Ra ≤ 0.1 μm).

4.2 Surface treatment and coating for car door panel injection mold

Advanced coating technologies are widely used to enhance automotive door panel mold durability. PVD coatings such as CrAlN achieve a surface hardness exceeding HV 3000 and offer five times greater corrosion resistance. Such coatings not only extend car door panel injection mold life but also reduce maintenance requirements during production.

5.Applications for Automotive Door Panel Mold

5.1 Automotive door panel mold in interior and exterior trim manufacturing

Automotive door panels are a vital part of a vehicle's interior and external trim, their design and manufacture directly affect the caliber of both the inside and outside of the car. High-quality car door panel injection molds guarantee accuracy and a smooth surface finish, therefore improving the premium feel of the car as a whole.

5.2 Automotive door panel mold in functional part integration

Modern vehicle door panels are more than just decorative features; they also integrate numerous functional components, such as speakers, storage compartments, and slots for electronic modules. The design of car door panel injection molds must take these functionalities into account, ensuring that each component fits perfectly for optimal performance.

5.3 Automotive door panel mold in lightweight design

With the automotive industry's pursuit of lightweighting, the design and material selection of car door panel injection molds are constantly evolving. Door panels made of lightweight materials not only reduce vehicle weight but also lower fuel consumption, improving fuel economy.

5.4 Automotive door panel mold in green and environmentally friendly production

With growing environmental awareness, automakers are also focusing on the environmental friendliness of their production processes. The manufacture and use of car door panel injection molds are increasingly incorporating recyclable materials and energy-saving technologies to achieve green production.