KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825The automotive industry's manufacturing speed is also speeding up as the market economy keeps growing; the frequency of product updates is dramatically growing. This change has a direct impact on the design and manufacture of vehicle lighting systems, therefore increasing the requirements for automotive lighting injection molds regularly. These automotive lamp injection molds are particularly made to create several automotive lights catering to the needs of several vehicle types; therefore, the quality of automotive lights is a major consideration influencing total car performance. Among these elements, the visual design of automobile lights has to be aligned with the general car appearance, be both aesthetically pleasing and simple to use, and satisfy aerodynamic design standards. Because these elements are vital, the design technology of automotive lighting injection molds is always changing in an effort to reach greater expectations and more sophisticated features. Among these factors, the appearance design of automotive lights must be coordinated with the overall vehicle appearance, being both aesthetically pleasing and easy to use, while also meeting aerodynamic design requirements. These factors are indispensable; therefore, the design technology of automotive lamp injection molds is constantly evolving, striving to achieve higher standards and more complex functions. |  |

Materials and Processing Characteristics of Automotive Lighting Injection Molds

Usually comprised two pieces—the lamp holder and the lamp cover—automotive lights Normally a thermosetting plastic like BMC (Bulk Molding Compound) serves as the lamp holder's raw material. Particularly well suited for automotive lamp holders, this material shows great structural integrity and heat resistance. Typically made of PMMA (polymethyl methacrylate), PP (polypropylene), and ABS (acrylonitrile-butadiene-styrene copolymer), lamp covers use a range of raw materials. For the color and optical performance of automotive lighting fixtures, these materials provide several choices.

Special care must be given to the two-color injection molding method in the processing of two-color or multi-color automotive lamp injection molds. The center distance between the two screws should be approximately consistent with the center distance of the two-color mold to ensure accurate fit and connection during injection molding. Moreover, two-color injection molding's success depends on two fundamental compatibility criteria: adhesive compatibility, which guarantees strong interaction between several materials; and process compatibility, which guarantees that several materials collaborate during injection molding to prevent manufacturing mistakes.

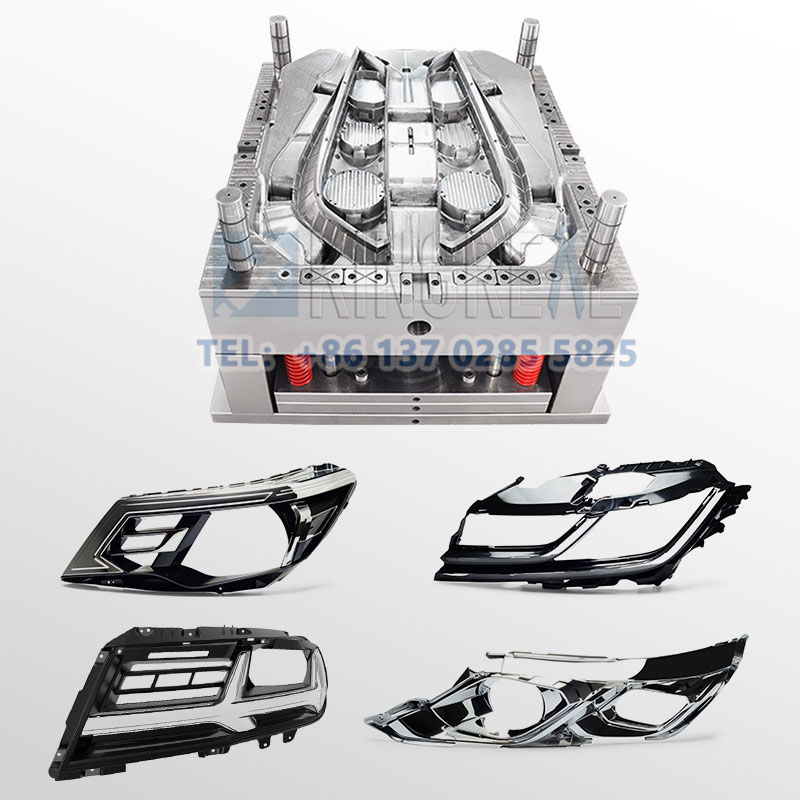

Automotive Lamp Injection Mold Design

Designing automotive lamp injection molds is a complex engineering project, the core of which lies in balancing the structural complexity of the mold with molding precision. Typically, the mold adopts an integrated structure design of "fixed mold plate A + moving mold plate B". The construction of the parting surface utilizes a combination of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, resulting in a smoother automotive lighting injection molds surface design and avoiding the accumulation of errors during CNC machining.

The design of the automotive lamp injection mold's cooling system is particularly crucial. Effective cooling can improve production efficiency and product quality. A combination of vertical water pipes and baffled water wells is typically used, maintaining a uniform distance of 15 to 25 mm between the cooling channels and the cavity surface. This design strategy effectively ensures that the injection cycle is controlled within 40 seconds, effectively avoiding warping and deformation problems caused by uneven cooling inside the automotive lighting injection molds. For high-precision automotive lamp injection molds, the side core-pulling mechanism is also essential. A mechanical drive structure of "moving mold slider + inclined guide pillars" enables precise demolding of complex undercuts. This structure, through the coordinated work of six independent sliders, meets the different precision requirements of lighting fixtures for new energy vehicles and traditional vehicles.

Automotive Lamp Injection Mold Quality Inspection

Achieving zero-defect manufacturing in the automotive lighting injection molds production process requires quality inspection at every level. Usually employed during the automotive lamp injection mold testing phase is a coordinate measuring machine to verify the cavity's dimensional correctness, so assuring that the tolerance is kept within ±0.02 mm. Such high requirements greatly lower scrap rates brought on by automobile lighting injection mold issues in following manufacturing, hence increasing general output efficiency. Besides shape and size, the appearance of injection molded parts also requires rigorous inspection, including optical performance testing and environmental simulation experiments. For example, lamps are continuously operated for 500 hours in an environment of 85°C and 85% humidity to verify their weather resistance and sealing performance. These tests not only affect product quality but also the safety and performance of the entire vehicle.

Technological Advancements in Automotive Lamp Injection Molds

In recent years, with continuous technological advancements, the design and manufacturing processes of automotive lighting injection molds have also evolved. For example, the adoption of digital and intelligent technologies has not only improved the accuracy of automotive lamp injection mold design but also increased production efficiency. The introduction of 3D printing technology has made mold sample production and adjustment faster, reducing development cycles and enabling quicker responses to market changes. Furthermore, the use of reinforced materials makes automotive lighting injection molds more durable and stable, extending their service life. The application of new composite materials and surface treatment technologies further improves the wear resistance and thermal stability of automotive lamp injection molds, thereby reducing the failure rate during production.

In conclusion, the importance of automotive lighting injection molds cannot be ignored. They not only affect the appearance and performance of the lights but also directly impact the safety, economy, and environmental adaptability of vehicles. If you require a customized automotive lamp injection mold manufacturing solution, please feel free to contact KRMOLD. KRMOLD automotive lighting injection molds are not only aesthetically pleasing but also structurally designed to meet complex requirements.