KINGREAL UNIVERSAL IND., LTD

Phone

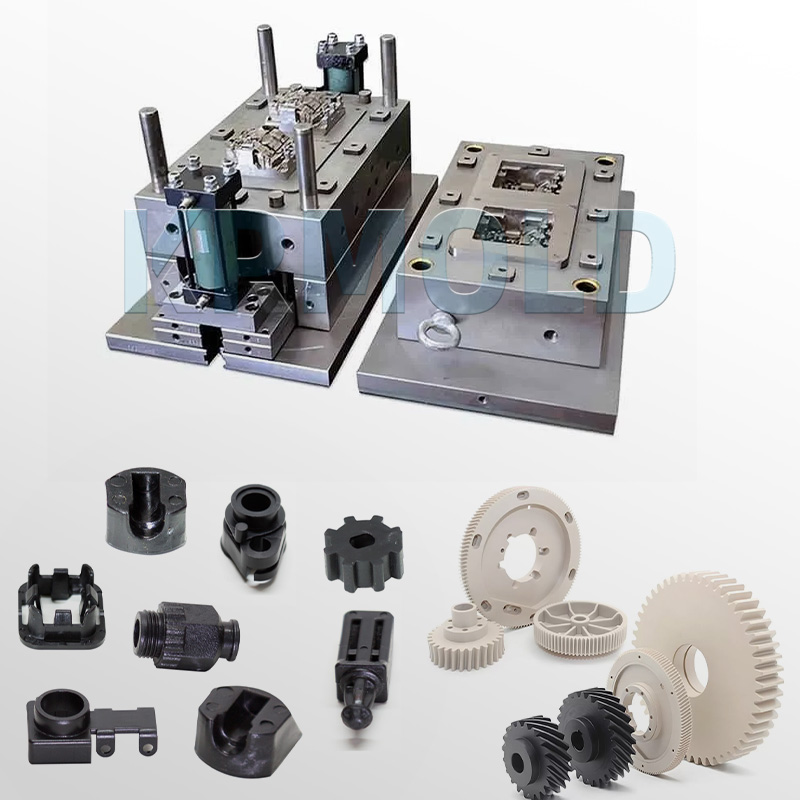

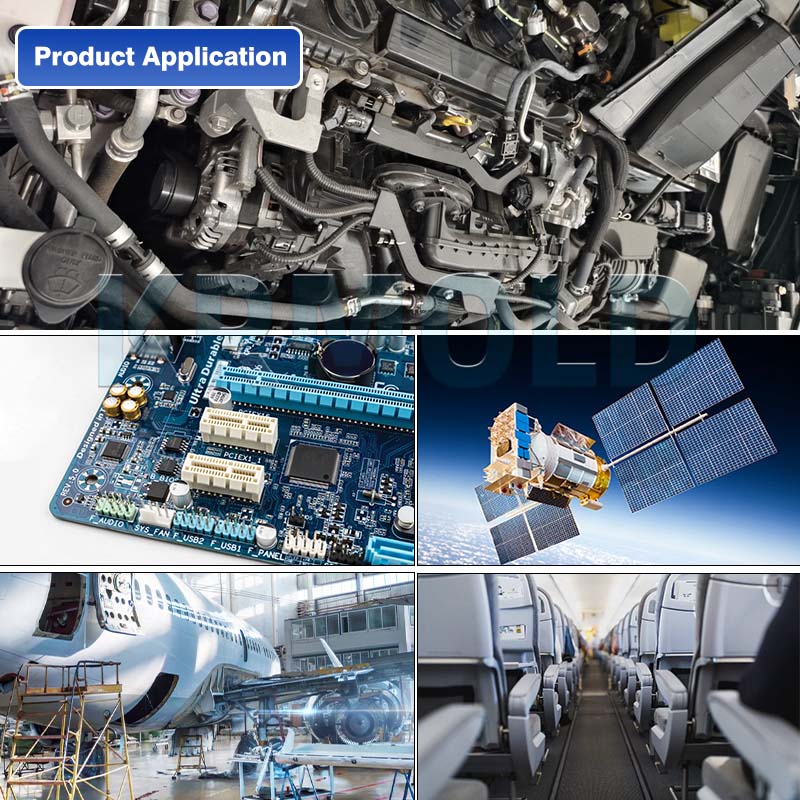

+86-13702855825PEEK injection molding is a common plastic injection molding process. In the field of high-end manufacturing, PEEK (polyetheretherketone) has become the preferred material for aerospace, medical equipment, automotive electronics and other industries due to its excellent high temperature resistance, chemical corrosion resistance and mechanical properties. However, the PEEK Plastic Injection Molding process has extremely high requirements for equipment, technology and process management, and the slightest carelessness may lead to product defects or substandard performance. In this article, KRMOLD will systematically analyze the core precautions of the PEEK injection molding process to help you avoid risks and achieve high-quality molding.

| 1 | Material properties and drying treatment: the cornerstone to avoid hydrolysis |

| 2 | Mold design and temperature control system: guarantee of precision PEEK plastic injection molding |

| 3 | PEEK injection molding process parameters: the key to balancing flow and degradation |

| 4 | Equipment and environment: rigid requirements for clean manufacturing |

| 5 | Post-processing and testing: the last link of performance verification |

1. Material properties and drying treatment: the cornerstone to avoid hydrolysis

PEEK is extremely sensitive to moisture. After absorbing moisture, it is easy to hydrolyze during the PEEK Injection Molding process, resulting in molecular chain breakage and decreased mechanical properties.

Strict drying: It needs to be dried in a hot air circulation oven at 150-160℃ for 4-6 hours to ensure that the moisture content is less than 0.02%.

Ready to use: PEEK after drying needs to be used within 2 hours to avoid re-absorption of moisture.

Material batch management: Different batches of PEEK may cause fluidity changes due to differences in molecular weight distribution, so it is necessary to test and adjust process parameters in advance.

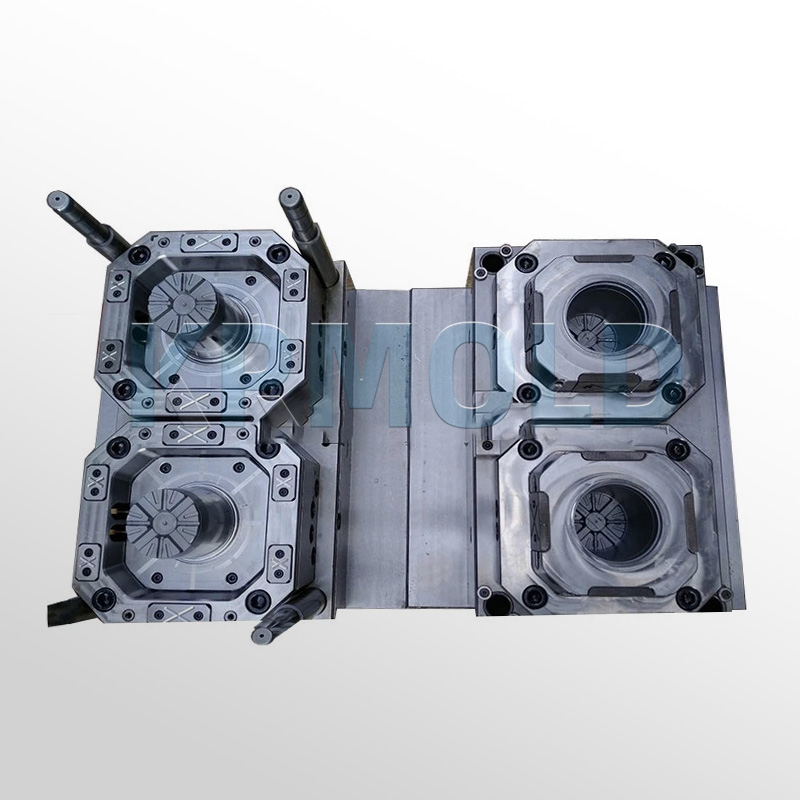

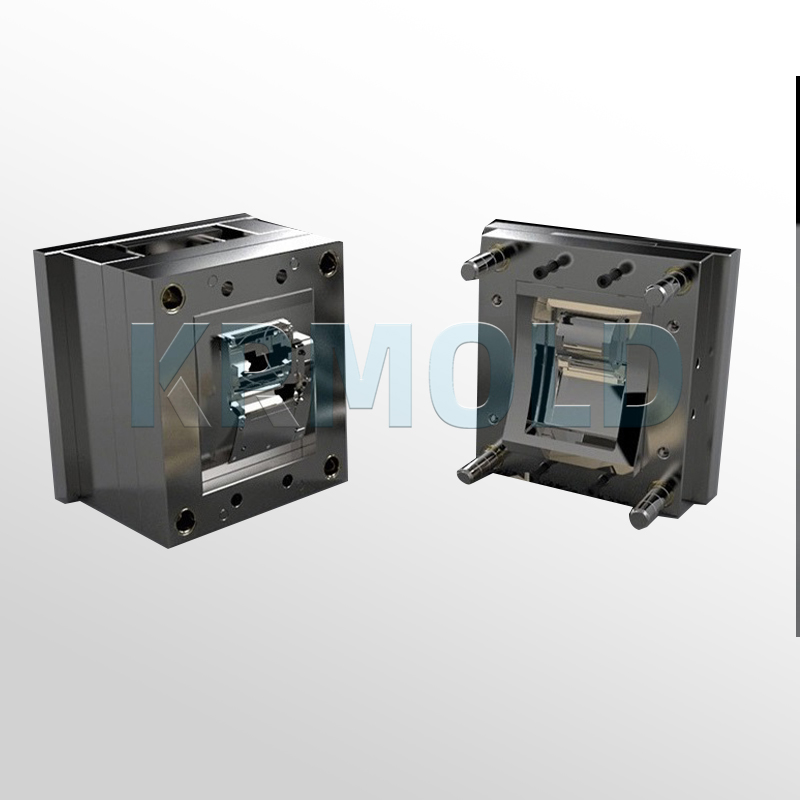

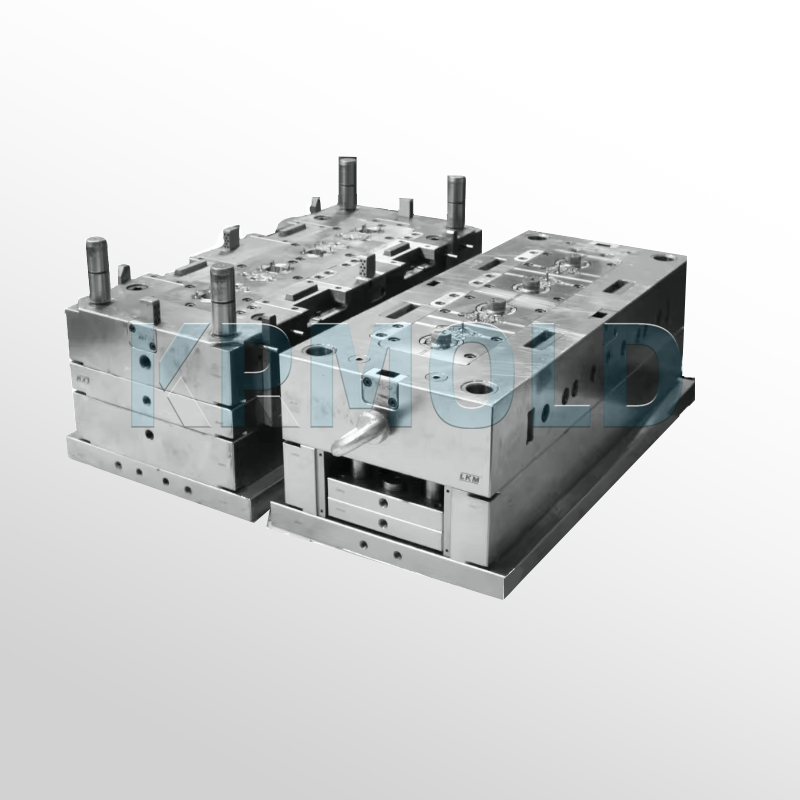

2. Mold design and temperature control system: guarantee of precision PEEK plastic injection molding

PEEK's high melting point (343℃) and low thermal conductivity require the mold to have efficient thermal management capabilities.

Hot runner design: A needle valve hot runner system is used to reduce material head residue and avoid carbides produced by PEEK decomposition from contaminating the mold cavity.

Mold temperature control: The mold temperature needs to be stable at 170-200℃. It is recommended to use a mold temperature controller to control the temperature in different zones to ensure the uniformity of the cavity temperature of ±3℃.

Exhaust optimization: PEEK melt has high viscosity and is easy to trap air. It is necessary to design an exhaust groove with a depth of 0.02-0.05mm at the parting surface and the gap between the inserts, and add a vacuum exhaust device if necessary.

3. PEEK injection molding process parameters: the key to balancing flow and degradation

PEEK Plastic Injection Molding requires rapid molding under high temperature and high pressure, but the thermal mechanical history needs to be strictly controlled.

Three-stage temperature control:

Barrel temperature: 380-420℃ (decreasing from front to back);

Nozzle temperature: 400-410℃ (prevent drooling);

Mold temperature: 180-200℃ (avoid internal stress caused by too fast cooling).

Injection speed and pressure: Use high-speed high-pressure injection (speed ≥100mm/s, pressure ≥150MPa) to shorten the residence time of the melt in the barrel and reduce the risk of degradation.

Pressure holding and cooling: The pressure holding pressure needs to be maintained at more than 80% of the injection pressure, and the cooling time is controlled at 30-60 seconds to avoid warping caused by premature mold opening.

4. Equipment and environment: rigid requirements for clean manufacturing

PEEK injection molding has strict requirements on equipment cleanliness and environmental stability.

Screw combination optimization: Use bimetallic screw (surface sprayed with wear-resistant alloy), the compression ratio is recommended to be 2.5:1-3:1 to reduce shear heat.

Clean production environment: The PEEK Plastic Injection Molding workshop must reach Class 10,000 cleanliness (ISO Class 7) to prevent dust particles from being embedded in the surface of the product.

Equipment maintenance: Regularly check the wear of the inner wall of the barrel to prevent PEEK carbide from adhering to the product and causing black spot defects.

5. Post-processing and testing: the last link of performance verification

The performance of PEEK products is highly dependent on the post-processing process.

Annealing treatment: Precision products need to be annealed at 200°C for 4 hours to eliminate internal stress and improve dimensional stability.

Performance testing:

Tensile strength ≥ 95MPa (ASTM D638);

Flexural modulus ≥ 3.5GPa (ASTM D790);

Weld line strength needs to be double-verified by CT scanning and mechanical testing.

Batch traceability: Establish a full-process quality file from raw materials to finished products to meet the traceability requirements of medical, aviation and other fields.

The difficulty of PEEK Injection Molding lies in the coordinated optimization of material properties, process parameters and equipment capabilities. Enterprises need to predict defects through digital simulation (such as Moldflow) and optimize the process window in combination with DOE experimental design. In the future, with the application of AI temperature control system and supercritical CO₂ assisted PEEK Injection Molding technology, the yield and efficiency of PEEK Plastic Injection Molding are expected to be further improved.

KRMOLD has been deeply involved in the field of PEEK injection molding for more than 20 years, successfully delivered medical and aviation-grade PEEK mold projects, and has a clean workshop and a full-process testing laboratory. If you need to customize PEEK injection molds or solve PEEK Plastic Injection Molding problems, please consult KRMOLD for professional solutions!