KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content:

01 Design of Agriculture Plastic Injection Mold

02 Applications of Agriculture Plastic Injection Mold

03 Role of Agricultural Machinery injection Molds

Improving the performance and productivity of mechanical equipment depends on agricultural machinery injection molds. Widely used in agricultural machinery like tractors, harvesters, and irrigation systems, these agriculture plastic injection molds create strong, lightweight, and accurate components. Technological developments have allowed the creation of agricultural machinery injection molds, hence more feasible, affordable, and easy manufacture of agricultural equipment.

01 Design of Agriculture Plastic Injection Mold

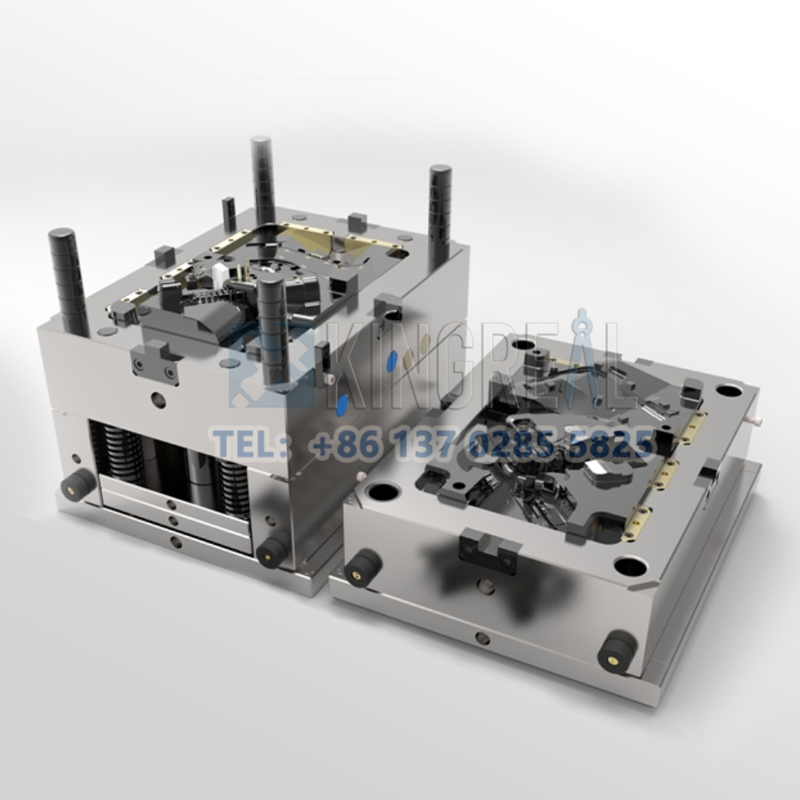

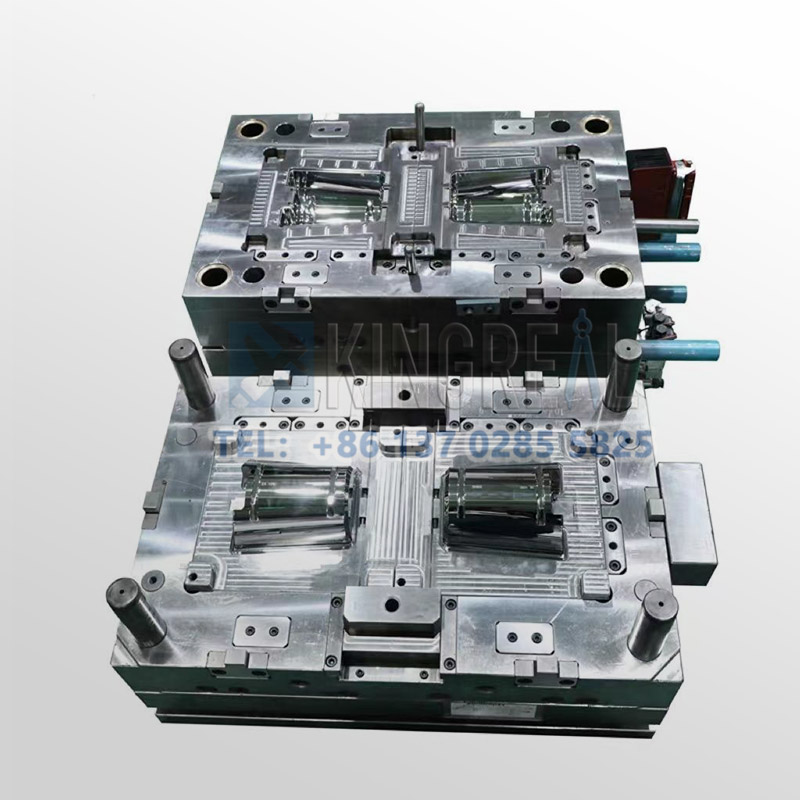

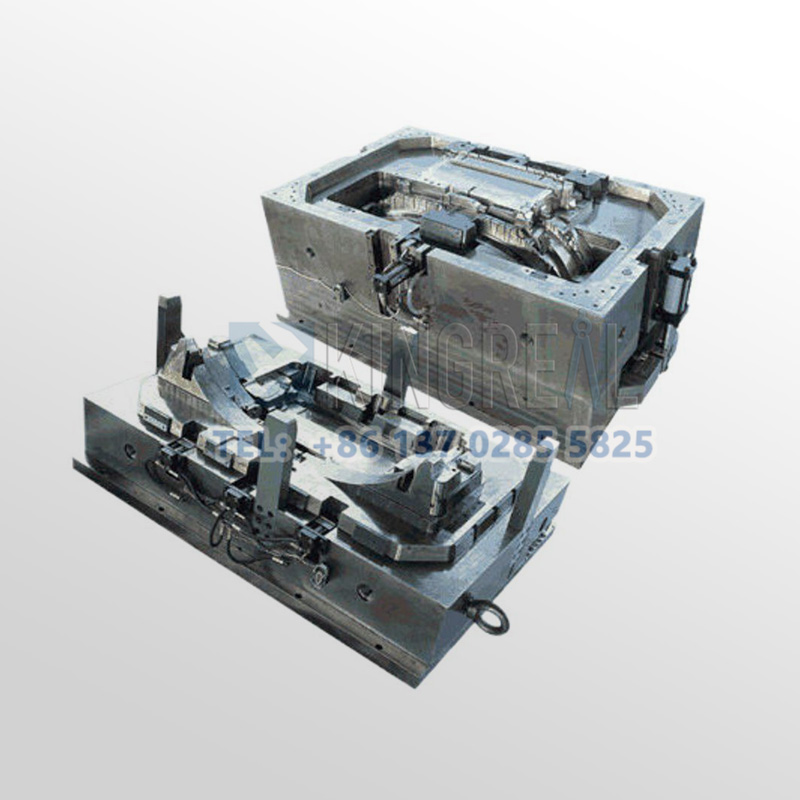

Designing agricultural machinery injection molds is a strict undertaking. Designers first need to have a thorough grasp of the component's requirements and specifications, which include its material properties, form, size, and the operational circumstances of the device. Professionals must ensure that the final agricultural machinery injection mold design meets certain agricultural applications by working closely with manufacturing teams and agricultural engineers throughout the design process. Engineers must choose excellent materials for agricultural machinery injection mold production once the design is finished. Good durability, wear resistance, and corrosion resistance are required for these materials, which must endure the high temperatures and pressures of injection molding. Alloy steel, aluminum alloys, and particular polymers are among the commonly used materials for agriculture plastic injection molds; they help to guarantee production stability and agricultural machinery injection mold lifetime.

The molded parts' quality depends on close regulation of temperature, pressure, and injection speed throughout the molding process. Lightweight but sturdy hollow parts made with many current molding techniques, including gas-assisted injection molding, greatly boost the performance of agricultural equipment components. Designs for agricultural machinery injection molds normally include cooling channels, ejector pins, and sliders to simplify mold disassembly and cleaning, hence guaranteeing a faultless production process. Moreover, exacting quality control throughout manufacture guarantees that the finished good satisfies market norms, hence maintaining agricultural equipment component competitiveness.

02 Applications of Agriculture Plastic Injection Mold

Parts produced by agricultural machinery injection molds are not only of high quality but also low cost, effectively meeting the needs of modern agriculture. Their applications are wide-ranging, particularly excelling in the following areas:

1)Agriculture plastic injection mold for plastic gears

Various components in tractors, harvesters, and plows, plastic gears are essential elements in agricultural equipment. Plastic gears, housings, and handles provide great corrosion resistance, resisting moisture and chemicals, hence guaranteeing regular operation under a range of severe conditions, and they are also lightweight.

2)Agricultural machinery injection mold for injection nozzles

Good water management is absolutely necessary in agriculture, especially in minimizing resource waste and managing crop moisture. Agriculture plastic injection mold assures premium nozzles and drip irrigation parts, therefore maximizing field irrigation results. While using sturdy plastic materials to boost resistance to water corrosion and fertilizer sedimentation, these parts are intended with exact forms to efficiently increase water consumption.

3)Agriculture plastic injection mold for storage and transportation solutions

Agricultural operations include the mass storage and transit of commodities. This industry mostly employs agricultural machinery injection mold to create crates, boxes, pallets, and other goods. Designed for effective stacking, these containers have great abrasion resistance and longevity, therefore perfect for application in many different contexts. Plastic materials have several benefits over metal or wooden elements, including lightweight, simple cleaning, and lower risk of contamination of stored food.

4)Agriculture plastic injection mold for livestock management

Additionally very important in livestock management is injection-molded equipment. Equipment used during breeding, including waterers and feeding troughs, has to be trustworthy and safe. Made using an agriculture plastic injection mold, these components resist the severe conditions of everyday use while preventing the intrusion of chemicals and microorganisms.

03 Role of Agricultural Machinery injection Molds

1)Mass production for agriculture plastic injection mold

Agricultural machinery injection molds enable the mass production of large quantities of highly consistent parts. Within acceptable tolerances, agriculture plastic injection molds can produce an astonishing number of identical parts; this stability is crucial in agricultural equipment manufacturing. Even minor variations can lead to equipment malfunctions. Therefore, agriculture plastic injection mold manufacturing significantly reduces production costs, making agricultural machinery production more efficient and economical.

2)Design flexibility for agricultural machinery injection mold

Agriculture plastic injection molds not only produce standardized parts, but their design flexibility allows for adjustments to meet specific project needs. Multiple functions can be integrated into a single part, reducing the number of parts and assembly complexity. This characteristic is particularly important in the agricultural sector, where many devices need to adapt to different operating conditions, requiring adjustability and flexibility to better suit actual production needs.