KINGREAL UNIVERSAL IND., LTD

Phone

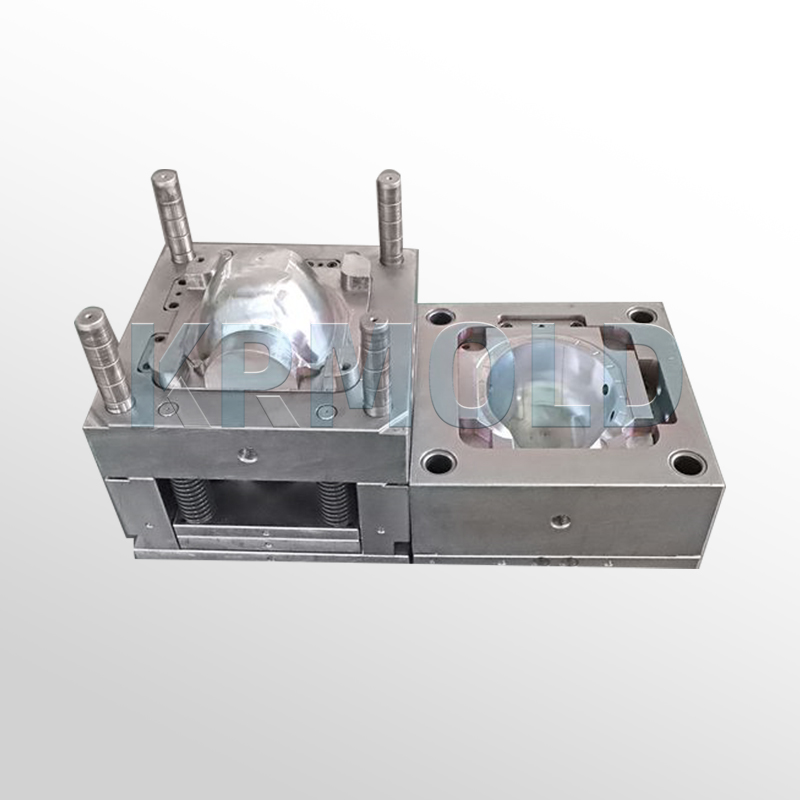

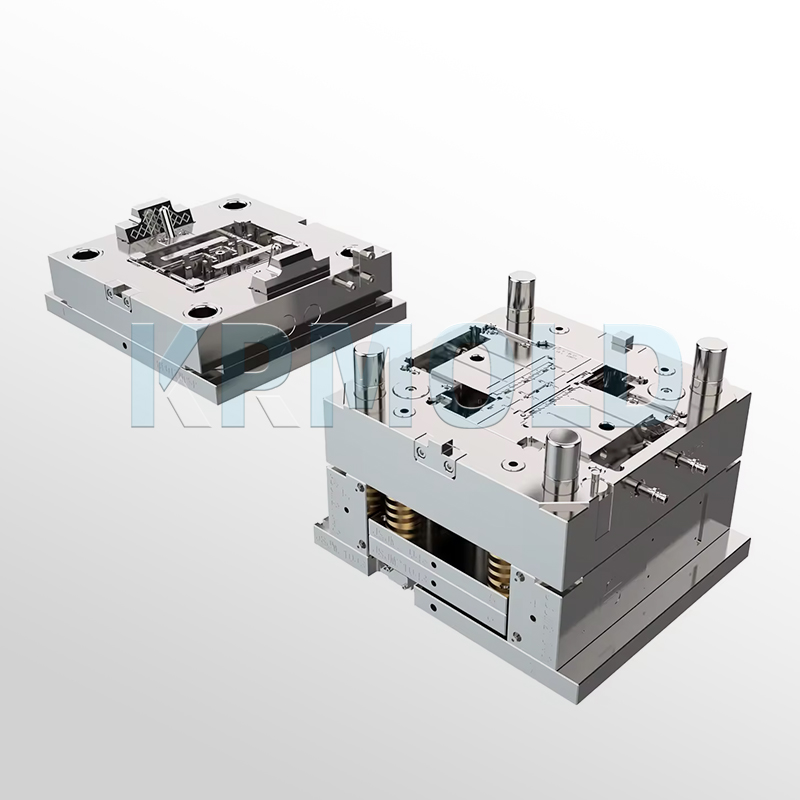

+86-13702855825PP Injection Molding has become one of the mainstream molding technologies in the field of plastic injection molding due to its unique material advantages and process flexibility, and occupies an important position in industrial manufacturing. Polypropylene has become one of the outstanding plastic injection molding technologies because it can adapt to multiple scenarios, has cost advantages and durability. It is polymerized from propylene monomers and naturally has the "genes" of high impact resistance, chemical corrosion resistance and low moisture absorption. The core means of converting it into an actual product is the classic injection molding process: injecting molten PP into a precision mold, and after cooling and solidification, a product of a predetermined shape can be obtained. From automotive parts to daily consumer goods, Polypropylene Injection Molding parts have penetrated almost every corner of modern life. Its ability to efficiently produce complex structural products makes it a "guest of honor" in industries such as automobiles, packaging, home appliances and medical equipment. This article will analyze the core characteristics of PP injection molding. If you are paying attention to this process or have the need for customized PP injection molds, please contact KRMOLD for professional solutions! |  |

| 1 | The Core Characteristics of PP Injection Molding |

| 2 | PP Injection Molding Process Conditions |

| 3 | Advantages of Polypropylene Injection Molding |

1. The Core Characteristics of PP Injection Molding

To fully utilize the processing potential of PP, we must first understand its material nature. These inherent characteristics are the key to its standing out among many plastics:

Outstanding mechanical performance: PP's tensile strength, impact resistance and flexibility are outstanding among general-purpose plastics. By adjusting the formula and adding toughening agents or fillers (such as talcum powder, glass fiber), its deformation resistance can be further improved to meet the strength requirements of structural parts.

Strong chemical corrosion resistance: PP shows excellent tolerance to acid, alkaline solutions and common organic solvents (such as alcohol and gasoline). Even if used for a long time in a humid or chemically corrosive environment, it is not easy to swell or degrade. It is particularly suitable for scenes such as chemical equipment accessories and outdoor protective parts.

Balanced thermal stability: PP has a melting point of about 160-170°C. Although it is not as high-temperature resistant as engineering plastics, it can maintain dimensional stability in conventional use (such as 80-100°C environment); at the same time, its thermal conductivity is low, and it is not easy to cause overall deformation due to heat conduction when locally heated. It is suitable for making household containers or industrial insulation parts that require temperature resistance.

Significant advantages in lightweighting: Compared with plastics such as ABS and PC, PP has a lower density (about 0.9g/cm³) and is lighter in weight at the same volume. This feature is particularly critical in the trend of lightweighting of automobiles - using Polypropylene Injection Molding parts can directly reduce the energy consumption of the entire vehicle and improve fuel efficiency.

Excellent moisture resistance: The moisture absorption rate of PP Injection Molding is only 0.01%-0.03% (much lower than nylon, polyester and other materials). After PP Injection Molding, it is not easy to shrink or warp due to water absorption. The product size accuracy is easier to control, which is suitable for scenes with high size requirements such as precision electronic accessories and optical device housings.

Biocompatibility meets standards: After modification, Polypropylene Injection Molding can meet medical grade requirements and is widely used in medical consumables such as disposable syringes, infusion bags, and surgical instrument kits. Its non-toxic and odorless characteristics also meet the standards for food contact materials and are commonly found in daily necessities such as fresh-keeping boxes and beverage cups.

From industrial equipment to people's livelihood products, the application boundaries of PP injection molding are still expanding. Whether it is the battery housing in the new energy field or the detachable panel of smart home appliances, Polypropylene Injection Molding has always been the preferred material in the manufacturing industry with its balanced advantages of "low cost + high performance". For manufacturers, if they want to gain an advantage in the competition, they must not only master the PP Injection Molding characteristics (such as shrinkage control and mold cooling design), but also pay attention to environmental protection trends - the development of low VOC (volatile organic compound) modified materials and recyclable PP composite materials are becoming an important direction for industry upgrading.

2. PP Injection Molding Process Conditions

① Drying treatment: Not required if stored properly.

② Dyeing and decoration: poor dyeing, uneven color powder diffusion (need to add diffusion oil/white sulfur oil), spraying or pad printing and other decorations, must be wiped with PP primer (commonly known as PP water) first.

③ Melting temperature: high crystallization, so the processing temperature is high. The front barrel is 200-240℃, the middle barrel is 170-220℃, and the rear barrel is 160-190℃. Be careful not to exceed 275℃. In order to reduce defects such as flash and shrinkage, the lower limit material temperature is often taken.

④ Mold temperature: 40-80℃, it is recommended to use about 50℃. The degree of crystallization is mainly determined by the mold temperature. If the mold temperature is too low (<40℃), the surface gloss of the plastic part is poor or even dull; if the mold temperature is too high (>90℃), warping, deformation, shrinkage and depression are prone to occur.

⑤ Injection pressure: The Polypropylene Injection Molding shrinkage is large, the size is unstable, and the plastic parts are easy to deform and shrink. The PP Injection Molding shrinkage can be reduced by increasing the injection pressure and injection speed and reducing the interlayer shear force. However, PP has good fluidity. When the injection pressure is high, it is easy to have flash and there are defects with strong directional characteristics. The injection pressure is generally 70-140MPa (if the pressure is too low, the shrinkage will be obvious). The holding pressure is about 80% of the injection pressure. It is advisable to take a longer holding time to compensate for shrinkage and a longer cooling time to ensure the size and deformation of the plastic parts.

Methods to reduce shrinkage: glass fiber (add 30%, it can be reduced to 0.7%)

⑥ Injection speed: The cooling speed is fast, and it is advisable to inject quickly. Appropriately deepen the exhaust groove to improve poor exhaust. For surface defects of plastic parts, use low-speed injection at a higher temperature. The volume of highly crystalline PP polymers will change greatly near the melting point. During cooling, shrinkage and crystallization will cause bubbles or even local hollowness inside the plastic parts (which will affect the mechanical strength of the parts). Therefore, adjusting the injection process parameters should be conducive to shrinkage compensation.

3.Advantages of Polypropylene Injection Molding

① Significant cost-effectiveness

PP Injection Molding is one of the most cost-effective thermoplastics in the current market. Its raw material cost itself is highly competitive, and the efficient operation characteristics of the superimposed PP Injection Molding process can achieve large-scale production of parts at a lower manufacturing cost, which is especially suitable for scenarios where the cost of end products needs to be controlled.

②Outstanding PP injection molding flexibility

Polypropylene Injection Molding exhibits excellent plasticity. It can not only shape small precision parts (such as electronic connectors) through PP Injection Molding, but also complete the Polypropylene Injection Molding of large and complex components (such as home appliance housings). This multi-form processing capability makes it widely applicable in both industrial manufacturing and daily consumer goods.

③Strong large-scale production capacity

As a mature manufacturing technology, the PP Injection Molding process has the characteristics of quickly producing large batches of products. This advantage is particularly critical for industries that require large-scale production, such as consumer electronics and daily necessities - the cycle from order receipt to finished product delivery can be greatly shortened, significantly improving the company's market response speed.

If you wanna know more information about Polypropylene Injection Molding, welcome to consult KRMOLD! We have a professional engineering team to answer the question about Polypropylene Injection Molding.