KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Characteristics of Plastic Plug Socket Injection Industry Demands |

| 2 | Core Design Challenges of Plastic Plug Socket Injection Mold |

| 3 | Plastic Plug Socket Injection Mold Materials and Surface Treatment Technology |

| 4 | Supply Chain Collaboration and Sustainable Development |

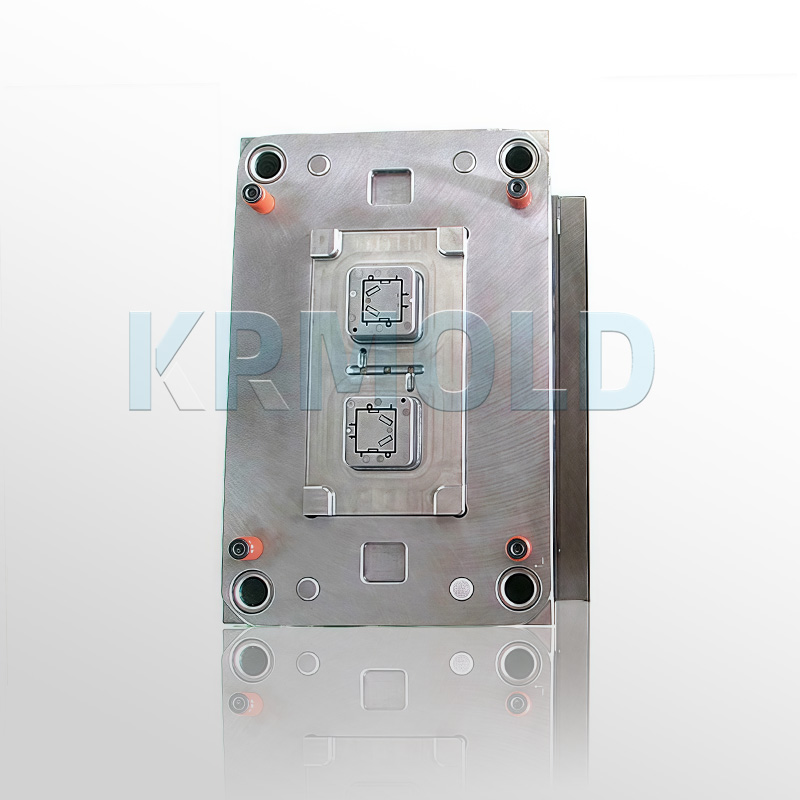

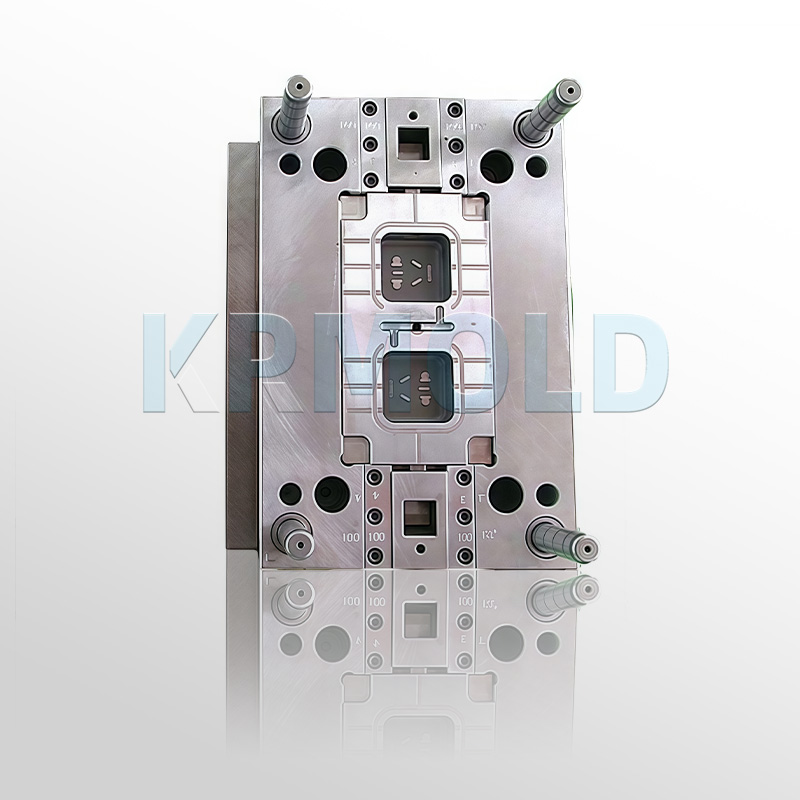

As the terminal interface for power transmission, the quality of socket panels directly affects electrical safety and user experience. All of this depends on the plastic plug socket injection molds used in the production process. This article will delve into the design and manufacturing technology system of switch socket plastic injection molds, revealing the precision engineering logic behind them.

1/ Characteristics of Plastic Plug Socket Injection Industry Demands

According to statistics from the International Electrotechnical Commission (IEC), more than 300 million socket panels are consumed globally each year, 80% of which are produced using injection molding. This large-scale production places unique demands on switch socket plastic injection molds:

●High Precision Requirements: The hole spacing tolerance of the socket panel must be controlled within ±0.02mm to ensure a perfect connection with the plug. This precision requirement is related to the safety of electrical equipment; any minute error may lead to poor contact, thus causing safety hazards.

●Fast Production Cycles: Mainstream plastic plug socket injection mold designs need to have an injection life of 800,000 to 1,000,000 cycles, with molding cycles typically compressed to less than 20 seconds. Fast production cycles not only improve production efficiency but also reduce production costs, enabling companies to maintain an advantage in fierce market competition.

●Safety Redundancy Design: Switch socket plastic injection molds must comply with the GB2099.1 national standard for shockproof structures to ensure the socket panel effectively protects user safety in the event of electrical equipment failure. This design requirement is reflected not only in the plastic plug socket injection mold structure but also in the selection of materials and optimization of processing techniques.

●Surface Treatment Standard: Surface treatment of the socket panel is also crucial. The Ra value of a matte textured surface needs to be controlled within the range of 0.8-1.6μm to achieve a good tactile feel and aesthetic effect. Surface treatment not only affects appearance but also improves scratch resistance and wear resistance, extending the service life of the socket panel. |  |

2/ Core Design Challenges of Plastic Plug Socket Injection Mold

The design of switch socket plastic injection molds faces multiple challenges, including balancing functionality, safety, and production efficiency. Here are some key challenges:

●Complex Geometry Control

Modern socket panels typically have multi-port configurations, such as 5-hole sockets, and may also contain undercut structures (slots) and thin-walled designs (1-2 mm). For example, a 5-hole plastic plug socket injection mold requires an accuracy of ±86 mm within a 0.2 × 86 mm area. To address these complex geometries, designers typically employ the following solutions:

(1)Angled ejector pin mechanism: Designed with an angle of 15°-25°, this allows for non-destructive demolding, avoiding product defects caused by mold structure.

(2)Optimized parting line: Designing the parting line on the bottom surface of the panel minimizes visible seams, enhancing the product's aesthetics and market competitiveness.

●Material-Process Synergy

Polycarbonate (PC) is the preferred material for switch socket plastic injection molds due to its high strength (Vicat softening point ≥145°C) and flame retardancy (UL94 V-0). However, its high melt viscosity (307-317°C) and low shrinkage (0.5%-0.7%) require extremely precise thermal control during injection molding. One case study showed that using dual-loop temperature control (accuracy ±0.5°C) reduced warpage from 0.744 mm to <0.25 mm. Furthermore, the application of a hybrid hot/cold runner system can limit melt temperature variations to ±3°C, significantly increasing production output.

3/ Plastic Plug Socket Injection Mold Materials and Surface Treatment Technology

Choosing the right materials and surface treatment technology is crucial for switch socket plastic injection mold life and product quality. Here are some common materials and their treatment methods:

| Components | Preferred Material | Heat Treatment | Surface Treatment |

| Cavity/Core | S136 Mirror Steel | Vacuum Quenching HRC48-52 | Nano PVD Coating |

| Slide Rail | 8407 Hot Work Steel | Nitriding (0.1mm layer) | TD Treatment |

| Ejector Pin | SKD61 | Cryogenic Treatment | DLC Coating |

Through composite surface treatment, the wear resistance of the plastic plug socket injection mold is improved by more than 3 times. One brand's plastic plug socket injection mold, after 0.008 million cycles, showed a wear of less than 3 mm on key components, demonstrating excellent durability.

4/ Supply Chain Collaboration and Sustainable Development

●Material Innovation

With increasing environmental awareness, material innovation has become an important trend in the switch socket plastic injection mold industry. Bio-based polycarbonate (PC) is one example, capable of reducing carbon emissions by 42%. Furthermore, the application of carbon nanotube (CNT) reinforced composites increases the flexural modulus of PC/ABS blends containing 2% CNTs by 35% in electric vehicle charging pads, improving product performance.

●Green Manufacturing

Green manufacturing is also the future direction of the plastic plug socket injection mold industry. Adopting a closed-loop water system allows for 95% water reuse, saving 120 tons of water per mold per year. Online recycling technology reprocesses materials using a twin-screw extruder, achieving a material utilization rate of 99.3%. These measures not only reduce production costs but also contribute to sustainable development.

KRMOLD hope this article provides valuable reference and inspiration for professionals in related industries. For more information on switch socket plastic injection mold, please contact KRMOLD!