KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content:

1. Superior Plastic Pallet Injection Mold Design and Manufacturing

2. Plastic Pallet Injection Mold Manufacturing Steps

3. Application of Plastic Pallet Injection Mold

4. Innovation and Development of Plastic Pallet Injection Mold

A logistic packaging injection mold, also known as a plastic pallet injection mold, is a high-strength injection mold specifically developed for producing plastic pallets used in warehousing, turnover, handling, and export logistics. This type of logistic packaging injection mold plays a crucial load-bearing role in the industrial logistics system, placing extremely high demands on its structural stability, load-bearing capacity, and molding efficiency. This article will delve into the various plastic pallet injection mold manufacturing solutions offered by KRMOLD, interpreting the logistic packaging injection mold manufacturing process and its wide applications.

1. Superior Plastic Pallet Injection Mold Design and Manufacturing

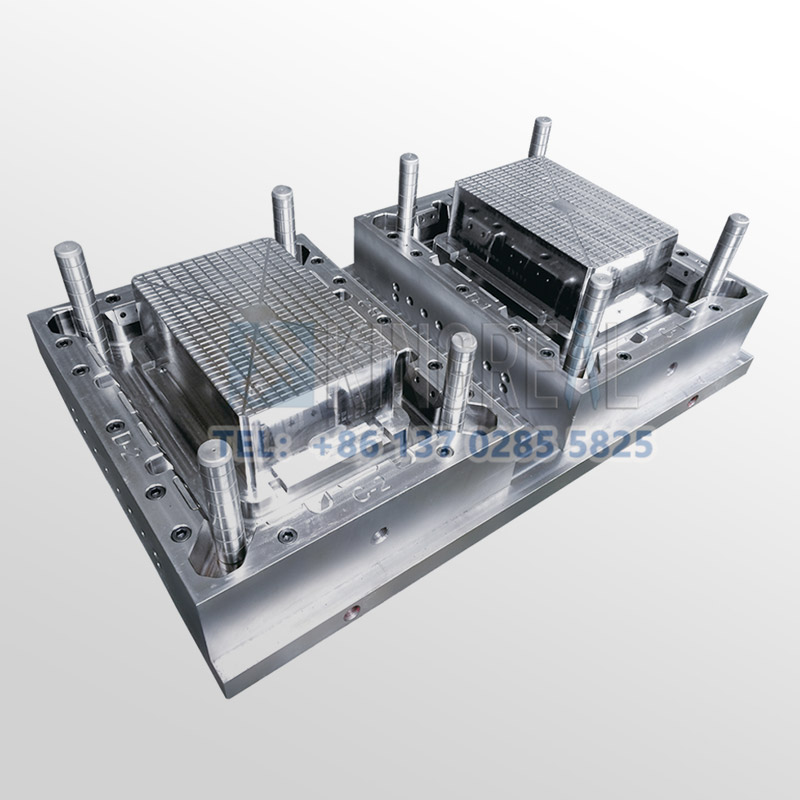

KRMOLD has established mature design and manufacturing capabilities in the field of logistic packaging injection molds. KRMOLD not only use high-strength mold steel as a base, but also employ advanced mold flow analysis technology and CNC precision machining equipment. These measures ensure that pallet products do not deform under heavy loads and possess excellent compressive and impact resistance.

1.1 Plastic Pallet Injection Mold Material Selection

The selection of mold materials is crucial to its strength and durability. The high-strength mold steel selected by KRMOLD can not only withstand high loads but also has excellent wear resistance. These characteristics result in a longer logistic packaging injection mold life and reduce potential downtime during production.

1.2 Diverse Pallet Structure Designs

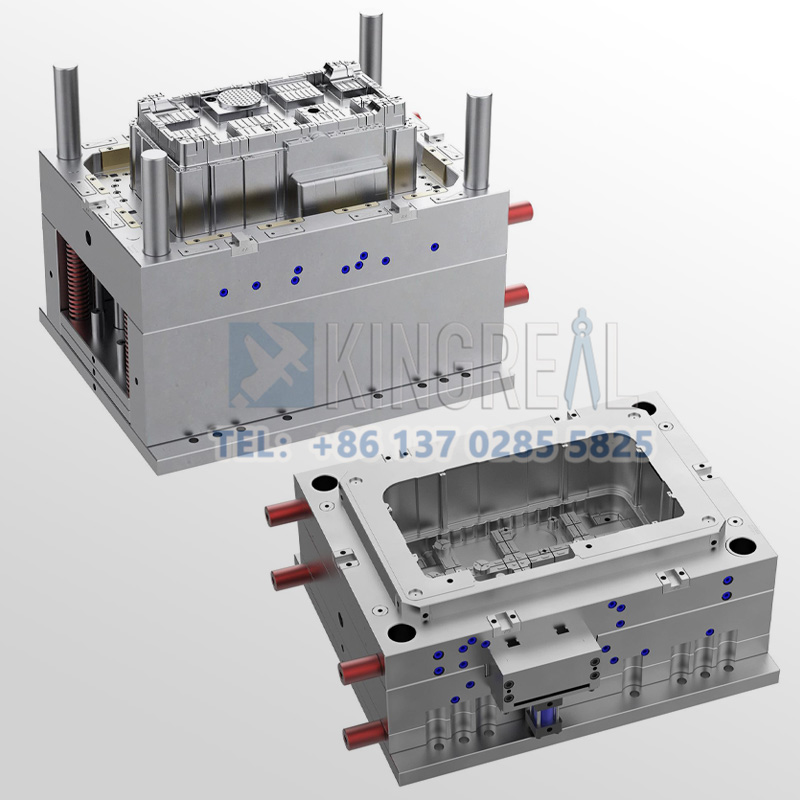

During the mold design process, KRMOLD fully considers the pallet's operating environment and supports the customized development of various pallet structures, including double-sided pallets, nine-legged pallets, grid pallets, and flat pallets. Through a rational runner and cooling system layout, injection efficiency is improved, and shrinkage and warping of the finished product are effectively controlled, ensuring dimensional stability and safe stacking of the pallets.

1.3 Modular Plastic Pallet Injection Mold Structure Design

KRMOLD logistic packaging injection molds feature a high degree of modularity, facilitating maintenance and component replacement. This design reduces customer operating costs and enhances production flexibility. The company's plastic pallet injection molds are widely used in automated warehousing, logistics transportation, cold chain distribution, and marine exports, helping customers build efficient, environmentally friendly, and recyclable logistics systems.

2. Plastic Pallet Injection Mold Manufacturing Steps

The logistic packaging injection mold manufacturing process is a complex and rigorous process, ensuring that each step efficiently and accurately improves plastic pallet injection mold quality. The following are the manufacturing steps for KRMOLD logistic packaging injection molds:

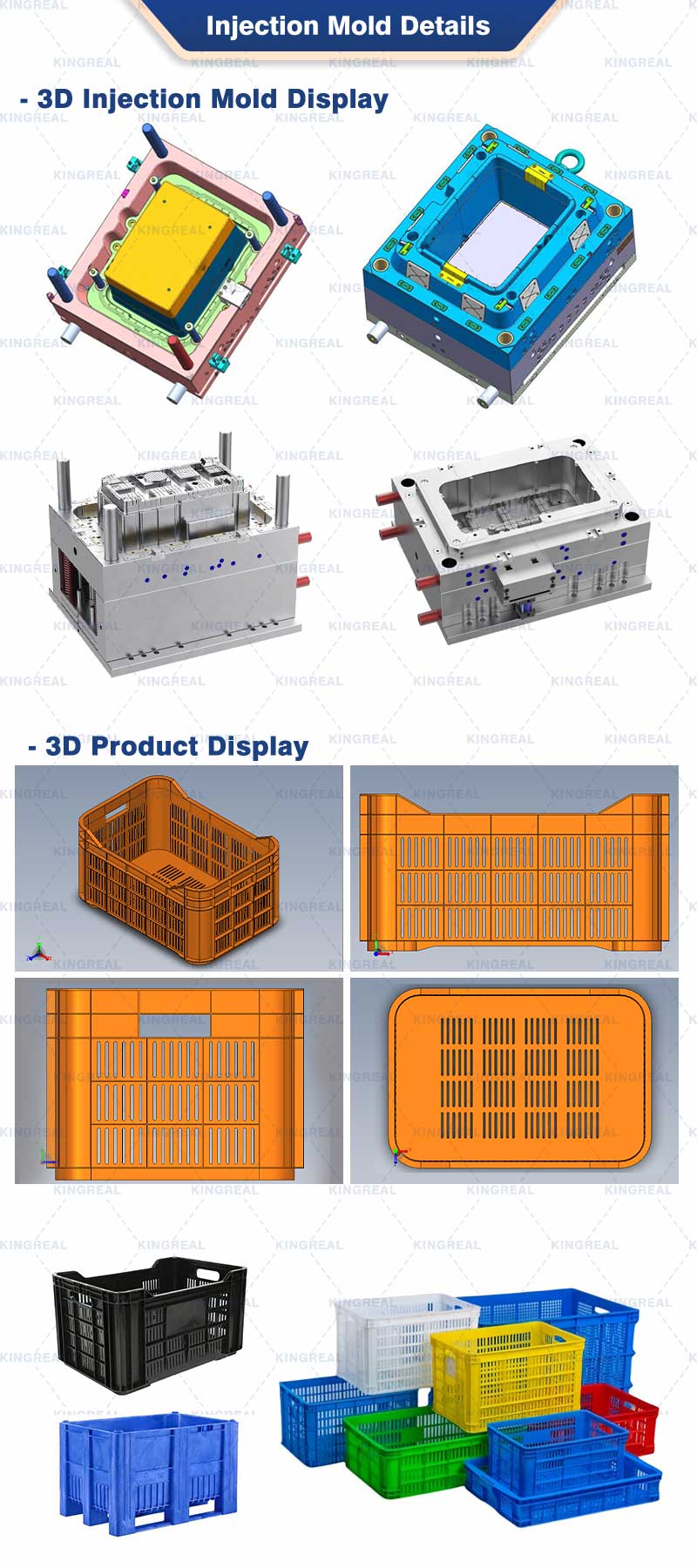

2.1 3D Design Analysis of Plastic Pallets

After receiving the customer's product design, KRMOLD convenes all relevant technical personnel to analyze the advantages and disadvantages of the design, as well as potential problems during processing. This includes in-depth analysis of draft angle, strength, plastic filling, deformation, wall thickness, and texture. Plastic pallet injection mold flow analysis is then conducted to ensure that KRMOLD staff can promptly contact the customer and provide solutions or suggestions should any problems be discovered.

2.2 Plastic Pallet Injection Mold Design Technical Meeting

All relevant personnel will participate in the new logistic packaging injection mold design technical meeting. At the meeting, KRMOLD staff will discuss the key technical aspects of the plastic pallet injection mold in detail, including the selection of mold component materials, basic structure, plastic material and its melt flow index, customer's special requirements, injection molding machine parameters, and component processing steps.

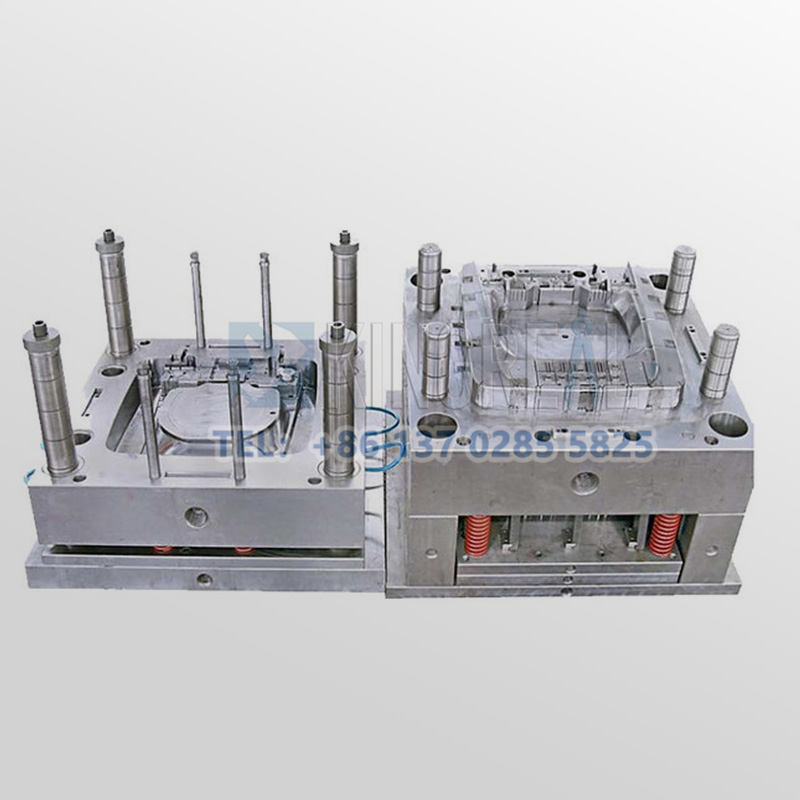

2.3 Plastic Pallet Injection Mold Design Inspection

After the logistic packaging injection mold design is completed, the plastic pallet injection mold design review department will review it. This review process includes logistic packaging injection mold structure inspection, mold movement and guiding system inspection, injection system inspection, cooling system inspection, ejection system inspection, and inspection of vulnerable parts.

2.4 Quality Control During Plastic Pallet Injection Mold Processing

During the mold processing process, KRMOLD staff implement strict quality control on the steel materials. The processing is divided into three steps: the first step is rough machining; the second step is semi-finishing of some precision logistic packaging injection molds; and the third step is high-speed milling for finishing. Throughout the process, KRMOLD consistently focuses on preventing deformation of the steel materials.

3. Application of Plastic Pallet Injection Mold

KRMOLD engineers design corresponding logistic packaging injection molds based on the customer's actual application scenarios. KRMOLD plastic pallet injection mold can produce many different types of pallets. Below are some examples of standardized pallets:

3.1 Plastic Pallet Injection Mold for Nine-Legged Grid Pallets

This logistic packaging injection mold's bottom structure uses multiple "nine-leg" support points combined with a grid-like load-bearing surface. This structure not only saves materials but is also lightweight, easy to use with manual forklifts, and facilitates ventilation at the bottom of the cargo box, making it a common choice for handling light goods. Nine-legged grid pallets are widely used in the food, daily necessities, and light industrial sectors.

3.2 Plastic Pallet Injection Mold for Ribbed Flat Pallets

This logistic packaging injection mold features continuous longitudinal ribs on the bottom (forming an "H" or "川" shape), resulting in a completely flat load-bearing surface. This ensures even load distribution and high overall strength, making it ideal for heavy-duty automated handling equipment (such as high-lift forklifts). This type of pallet is particularly suitable for the storage and handling of heavy goods.

3.3 Plastic Pallet Injection Mold for Double-Sided Flat Pallets

The design of double-sided flat pallets allows for flat load-bearing surfaces on both the top and bottom, enabling stacking from either side. Its internal rib layout requires special reinforcement to ensure rigidity on both sides, resulting in a relatively higher weight, but it is ideal for goods requiring highly stable stacking. Double-sided flat pallets are widely used in industries such as automotive parts, electrical equipment, and heavy machinery.

4. Innovation and Development of Plastic Pallet Injection Mold

With the continuous development of the logistics industry, the demand for logistics packaging injection molds is also increasing. KRMOLD always stays at the forefront of technology, constantly introducing new technologies, materials, and processes to improve plastic pallet injection mold performance and service life.

4.1 Adoption of New Environmentally Friendly Materials

In an environment of increasingly stringent environmental policies, KRMOLD actively develops and utilizes new environmentally friendly plastic materials to make the logistic packaging injection mold production process greener. These new materials not only possess excellent mechanical properties but also reduce carbon emissions during production, meeting the requirements of modern sustainable development.

4.2 Intelligent Production

KRMOLD is gradually transforming towards intelligent production, utilizing IoT technology for real-time monitoring of the production process and improving production efficiency and logistic packaging injection mold quality through data analysis. Intelligent production lines enable greater efficiency and precision at every stage, significantly shortening the production cycle.