KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825"KRMOLD helps American automotive manufacturing customers complete a series of process services such as the design, manufacture and modification of car audio speaker cover injection molds, helping American customers solve the injection molding manufacturing needs of speaker protection covers in car audio systems in the manufacturing of automotive parts, and has won high praise from American customers.

Car Audio Speaker Cover Injection Mold achieves high-quality production of car audio covers through precise design and efficient processes. It has the advantages of integrated molding technology and cost optimization, while meeting the automotive industry's stringent requirements for functionality, aesthetics and reliability."

Car Audio Speaker Cover Injection Mold Specification

| Export Country | American |

| Mold Size | 850*550*540 mm |

| Mold Weight | 1260 kg |

| Number Of Slide | 8 PCS |

| Number Of Lifter | No |

| Part Material | PP 4800LMNBC |

| Part Weight | 93 g |

| Lead Time | 35 days |

| Trial Times | 2 |

Mold Type | Production mold |

| Cavity Steel | Cut in 738H solid |

| Mold Base | DME-2# |

| Number Of Cavity | 1+1 |

| Number Of Hydraulic | No |

| Interchangeable Inserts | 2PCS |

| Ejection | Ejector Pin |

| Mold Standard | DME Equivalent |

| Surface Finish | B2 (400# Paper) |

How To Design An Injection Mold For Car Audio Speaker Cover?

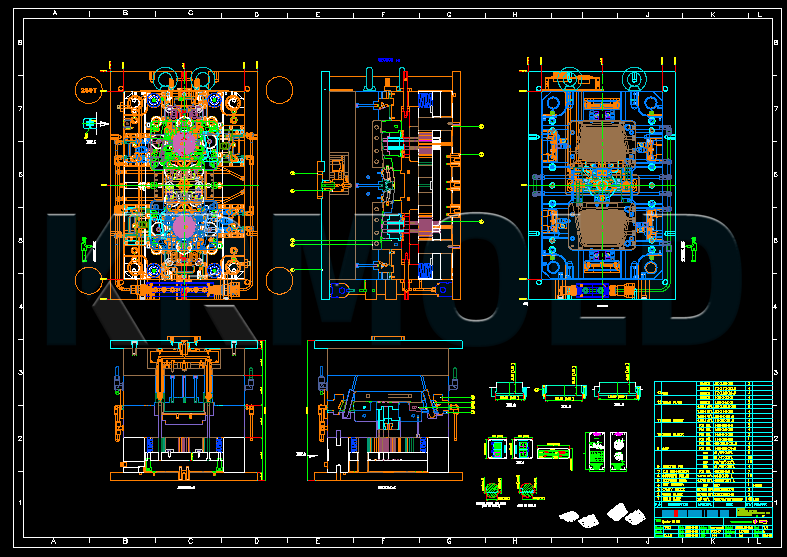

1. 2D Drawing For Car Audio Speaker Cover Mold

KRMOLD designed the Car Audio Speaker Cover Mold 2D drawing. The main view and section view clearly define the parting line position along the edge of the speaker cover or the mesh area, and mark the cavity shape of the front mold core and the rear mold core to ensure that the product is not damaged during demolding. Display the hot runner system of the dual hot runner layout and the location of the latent gate or point gate to avoid the weld line affecting the appearance

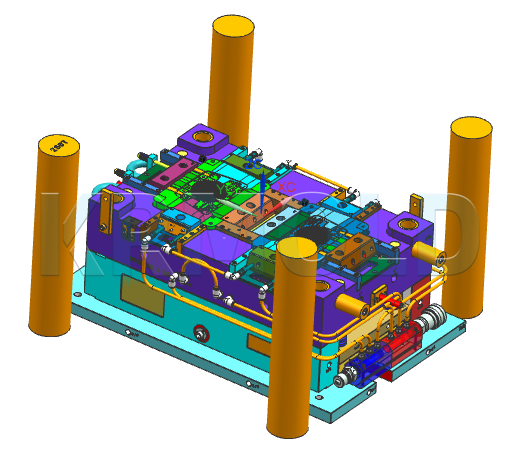

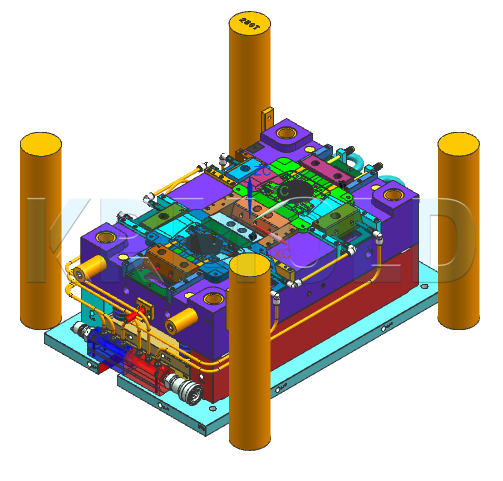

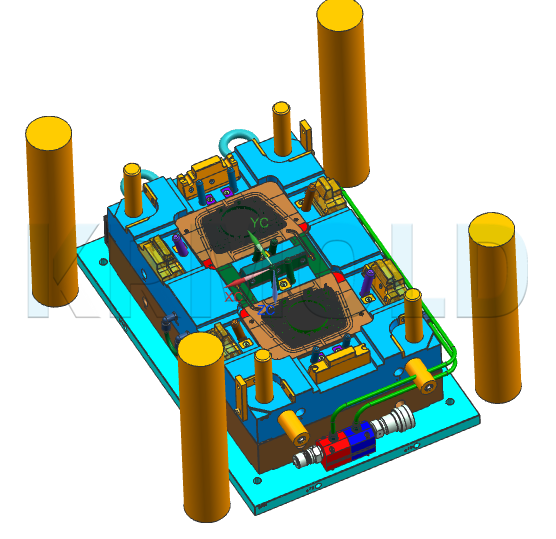

2. 3D Drawing For Car Audio Speaker Cover Mold

KRMOLD engineers use UG, Solid-Works and other 3D modeling software to build digital design files of Car Audio Speaker Cover Mold, which are used to fully display the mold structure, functional modules and manufacturing process. Compared with 2D drawings, 3D drawings are presented in three-dimensional, dynamic and parameterized form, which can more intuitively guide mold processing and verification.

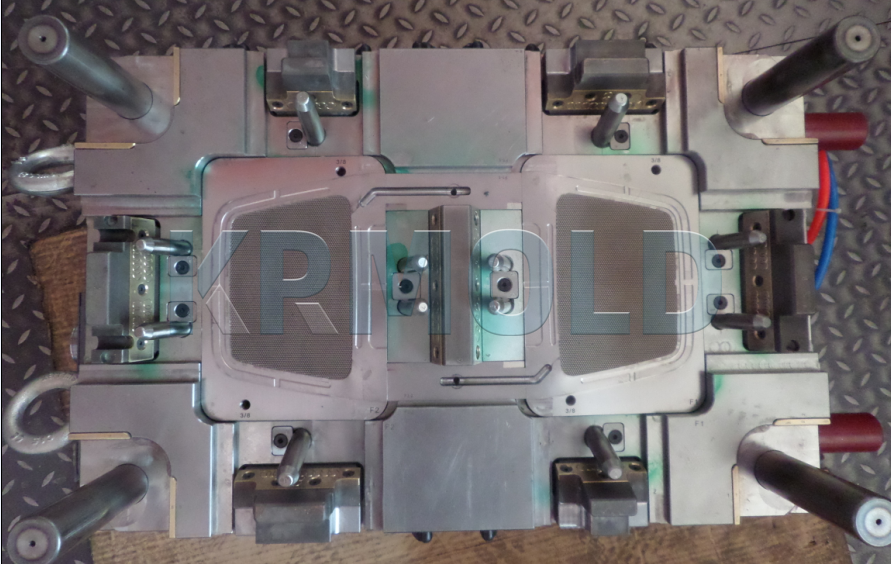

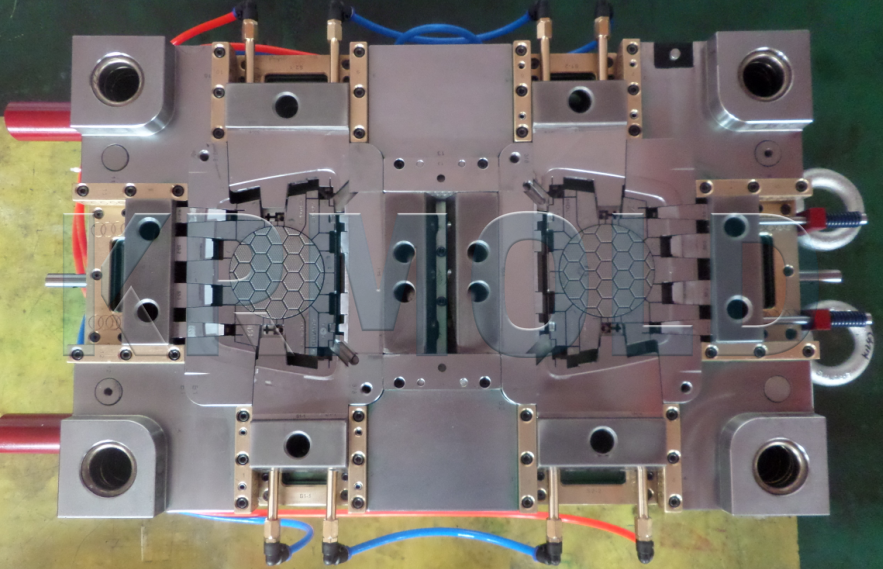

Car Audio Speaker Cover Injection Mould Display