KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content:

1/Basic Concepts of Car Wheel Arch Liner Injection Mold

2/Definition of Automotive Wheel Arch Liner Injection Mold Manufacturing Precision

3/Impact of Car Wheel Arch Liner Injection Mold Manufacturing Precision on Product Quality

4/Impact of Car Wheel Arch Liner Injection Mold Manufacturing Precision on Production Efficiency

5/Technical Means to Improve Car Wheel Arch Liner Injection Mold Manufacturing Precision

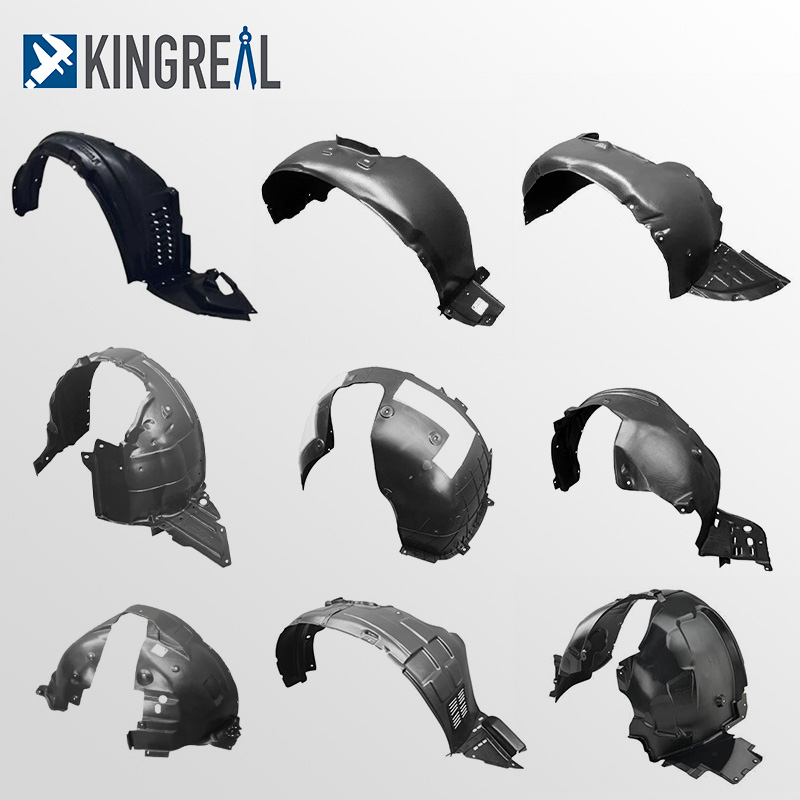

Automotive wheel arch liner injection molds are not only key equipment for producing high-quality wheel arch liners, but also crucial components for ensuring the overall performance of a vehicle. Extending the lifetime of the car's chassis, wheel arch liners primarily protect the chassis from mud, sand, rocks, and other trash. They also stop rainfall from entering the chassis in bad weather, therefore lowering the risk of rust. Furthermore, excellent wheel arch liners can considerably lower tire noise and enhance riding comfort. High-quality wheel arch liners can lower interior noise by 3-5 decibels. Therefore, manufacturing precision is particularly important in car wheel arch liner injection molds. This article will explore in depth why the manufacturing precision of automotive wheel arch liner injection molds is so critical.

1/Basic Concepts of Car Wheel Arch Liner Injection Mold

The injection molding process for automotive parts begins with material preparation. Technicians typically use plastic granules or pellets, which are dried before use to remove moisture. Next, technicians mix the customer's required dyes and other additives into the dried granules to ensure the final product's color and performance meet requirements.

After preparation, the raw materials are placed into the injection molding machine. At this point, the plastic granules are heated to a molten state inside the injection molding machine. The molten plastic is then injected under high pressure into the closed automotive wheel arch liner injection mold to ensure that each cavity is fully filled. After the melt is injected, the car wheel arch liner injection mold enters the cooling stage, where coolant circulates in the automotive wheel arch liner injection mold's cooling channels to rapidly freeze the plastic. Once the material has cooled, the final molded part is ejected from the mold via ejector pins or ejector plates, and then enters the quality inspection stage.

Car wheel arch liner injection molds are essential in the automotive sector for creating strong, accurate, high-performance automotive wheel arch liner parts. High-precision automotive wheel arch liner injection mold makes it possible to create intricate forms and geometries quickly, therefore guaranteeing product consistency and dependability.

2/Definition of Automotive Wheel Arch Liner Injection Mold Manufacturing Precision

Understanding why the manufacturing accuracy of car wheel arch liner injection molds is crucial requires first defining several main variables influencing the processing precision of automotive wheel arch liner injection mold manufacturing.

1. Material selection for car wheel arch liner injection molds

The performance and lifetime of the automotive wheel arch liner injection mold are directly determined by the selection of mold material. Most injection molding manufacturing may be met by common mold steels, which have great hardness, toughness, and wear resistance. Higher strength and heat resistance requirements of molds in the automobile industry call for careful material choice.

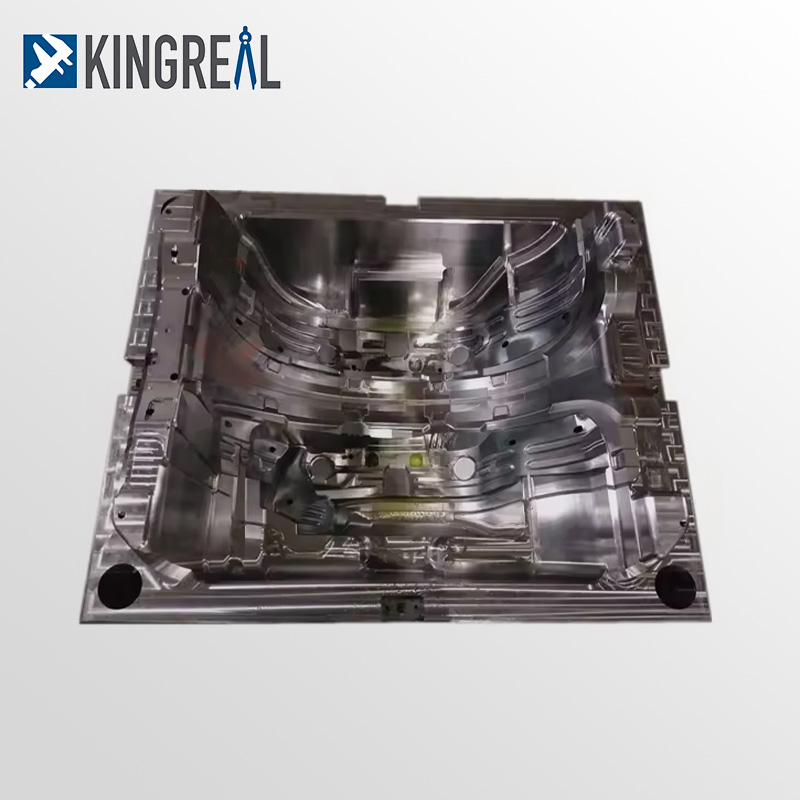

2. Car wheel arch liner injection mold structural design

A reasonable automotive wheel arch liner injection mold structural design is fundamental to ensuring a smooth injection molding process. The design includes gate location, runner system, and cooling system, all of which are important factors affecting car wheel arch liner injection mold precision. For example, an optimized gate design allows the molten plastic to fill the mold cavity evenly, reducing deformation and defects in the finished product.

3. Automotive wheel arch liner injection mold precision control

High-precision car wheel arch liner injection mold design ensures the dimensional and shape accuracy of injection-molded products. This is particularly important for automotive parts manufacturing, as these components often need to operate within very tight tolerances. Advanced processing equipment and testing methods are key to ensuring automotive wheel arch liner injection mold precision.

3/Impact of Car Wheel Arch Liner Injection Mold Manufacturing Precision on Product Quality

Automotive wheel arch liner injection mold precision directly impacts the quality of injection-molded products. High-precision car wheel arch liner injection molds ensure smooth surfaces, accurate dimensions, and meet stringent quality requirements. Improved mold precision also stabilizes the injection molding process, reduces fluctuations in scrap rates and molding shrinkage, thereby increasing production efficiency.

High-quality mold materials, reasonable design, and advanced manufacturing technology are all guarantees for achieving high precision. Furthermore, strict control of injection molding process conditions is also crucial, effectively ensuring the stability of the injection molding process. Therefore, automotive wheel arch liner injection mold precision not only directly affects the quality of the final product but also impacts overall production efficiency. It is imperative to give automotive wheel arch liner injection mold accuracy top priority by means of modern techniques and strict management to guarantee the success and competitiveness of injection molding.

4/Impact of Car Wheel Arch Liner Injection Mold Manufacturing Precision on Production Efficiency

The impact of manufacturing precision on production efficiency is mainly reflected in the following aspects:

1. Reduced car wheel arch liner injection mold debugging time

High-precision automotive wheel arch liner injection mold design can reduce debugging time. Car wheel arch liner injection molds require multiple adjustments during production to ensure they can stably produce parts that meet requirements. Higher automotive wheel arch liner injection mold manufacturing precision naturally reduces the debugging time, thereby improving production efficiency.

2. Reduced scrap rate for car wheel arch liner injection mold

Automotive wheel arch liner injection mold precision directly affects the finished product pass rate. High-precision car wheel arch liner injection molds can effectively reduce the scrap rate during production. Compared to low-precision automotive wheel arch liner injection molds, high-precision car wheel arch liner injection molds ensure fewer defects during production, thereby reducing losses due to defective products.

3. Increased production speed for car wheel arch liner injection mold

The high-precision automotive wheel arch liner injection molds' stability makes the manufacturing process more streamlined, therefore lowering downtime and therefore boosting the overall production line speed. With increased production speed, companies can complete more production tasks in less time, thereby improving economic efficiency.

5/ Technical Means to Improve Car Wheel Arch Liner Injection Mold Manufacturing Precision

To improve the manufacturing precision of automotive wheel arch liner injection molds, the following technical means can be adopted:

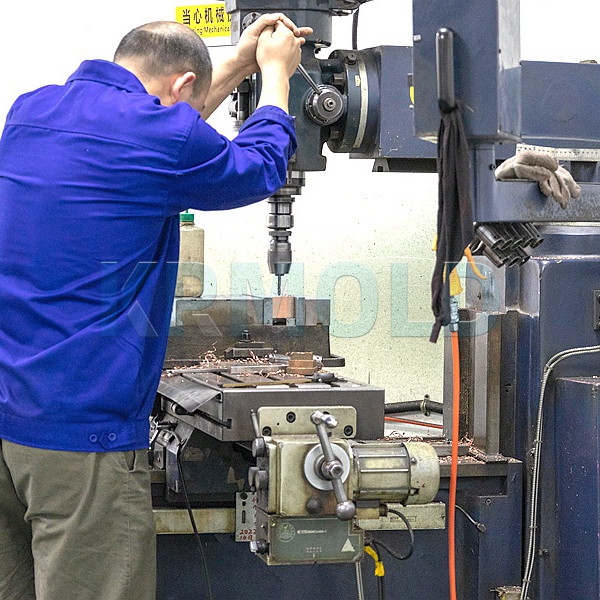

1. Advanced machining technology

Using advanced CNC machining technology can ensure high precision in the car wheel arch liner injection mold manufacturing process. CNC machine tools can process every detail of the automotive wheel arch liner injection mold with extremely high precision, ensuring its accurate dimensions and shape.

2. Precision measurement and inspection technology

During the automotive wheel arch liner injection mold manufacturing process, using precision measurement and inspection equipment allows for real-time monitoring of the car wheel arch liner injection mold's manufacturing precision, timely detection and correction of potential problems, thereby ensuring the final quality of the automotive wheel arch liner injection mold.

3. Material selection and treatment

Selecting suitable car wheel arch liner injection mold materials and performing appropriate heat treatment can improve the automotive wheel arch liner injection mold's hardness and wear resistance, thereby increasing the automotive wheel arch liner injection mold's service life and precision.