KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content

01/Process of Making Auto Sensor Parts Mold

02/Understanding Plastic Auto Parts Sensor Mold Components

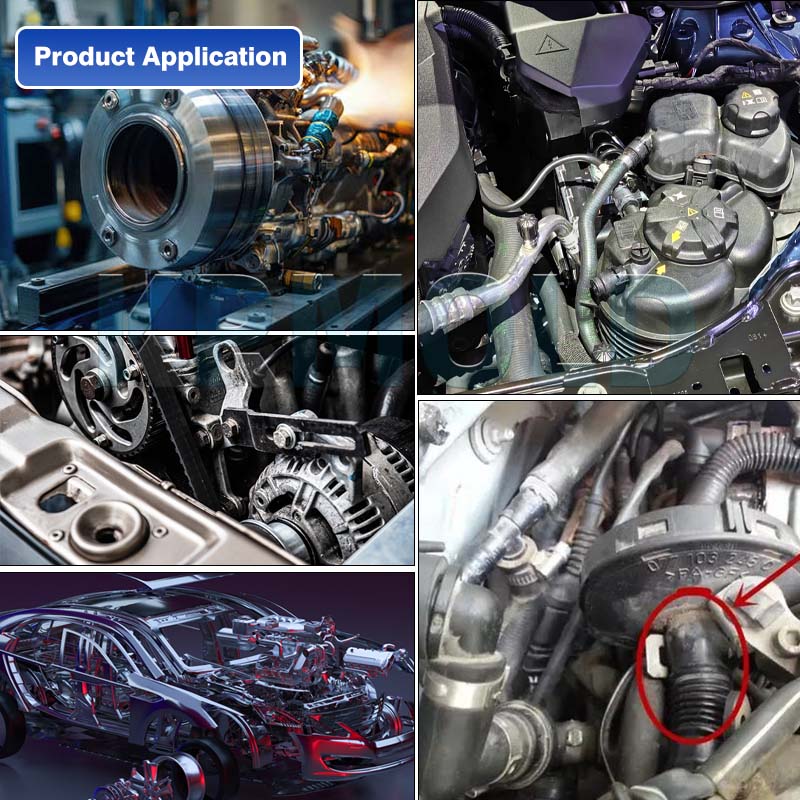

Plastic auto parts sensor molds are crucial tools for manufacturing high-precision plastic sensor components, which are widely used in various systems of modern automobiles. With the continuous advancement of automotive electronics technology, the production of reliable auto sensor parts molds has become particularly important. This article details how to ensure the reliability and quality of plastic auto parts sensor molds, from mold design, manufacturing, testing and verification to mass production.

01/Process of Making Auto Sensor Parts Mold

Step 1: Design phase of auto sensor parts mold

●CAD design for auto sensor parts mold

First, in the design phase of plastic auto parts sensor molds, CAD software is widely used. Designers need to create 3D/2D models of the parts and auto sensor parts molds, and define geometric dimensions and tolerances. Furthermore, a reasonable draft angle design helps with smooth demolding and reduces wear on the plastic auto parts sensor mold. The design quality at this stage directly affects the smooth progress of subsequent processes, therefore it must be accurate and conform to industry standards.

●DFM analysis for auto sensor parts mold

DFM analysis is also an indispensable step. This includes a detailed analysis of factors such as wall thickness, reinforcing ribs, and corner radii, all of which affect warpage and shrinkage marks in the finished product. At this stage, designers need to consider material properties, molding process limitations, and production efficiency to design a plastic auto parts sensor mold that is both productive and suitable for manufacturing.

●Mold flow analysis for auto sensor parts mold

Furthermore, mold flow analysis is a crucial tool for ensuring the rationality of plastic auto parts sensor mold design. By simulating the flow of molten plastic in the auto sensor parts mold, designers can evaluate factors such as fill balance, weld lines, cavitation, cooling, and deflection. Mold flow analysis helps identify potential problems and make corresponding adjustments to ensure the performance of plastic auto parts sensor molds in actual production.

Step 2: Auto sensor parts mold manufacturing

●Material selection for auto sensor parts mold

The choice of materials for plastic auto parts sensor mold manufacturing is crucial to the mold's lifespan and stability. Commonly used mold materials include P20, H13, S136 stainless steel, and aluminum alloys, depending on the operating environment and molding requirements. Each material has its unique properties, and designers must make appropriate selections based on specific needs.

●CNC machining for auto sensor parts mold

The finishing and roughing of plastic auto parts sensor molds are mainly achieved through CNC machine tools to ensure the geometric accuracy of the auto sensor parts mold. This process requires extremely high precision to ensure the yield and consistency of injection molded parts. Furthermore, EDM is a commonly used method when dealing with complex mold structures, capable of handling intricate details such as deep cavities and sharp corners.

●Polishing and texturing for auto sensor parts mold

Plastic auto parts sensor mold surface treatment includes polishing and texturing. Optical polishing achieves a highly smooth surface, while texturing (such as VDI/MT standards) creates appropriate textures on the auto sensor parts mold surface, which is crucial for improving the appearance and adhesion of parts. Surface treatment is not just an aesthetic issue; it directly affects the demolding performance and lifespan of plastic parts.

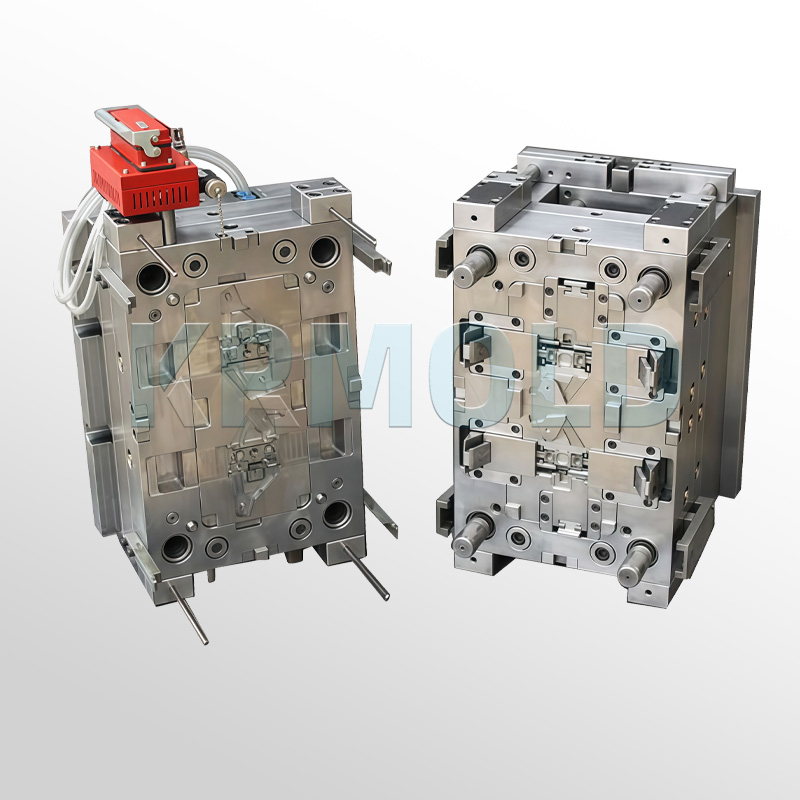

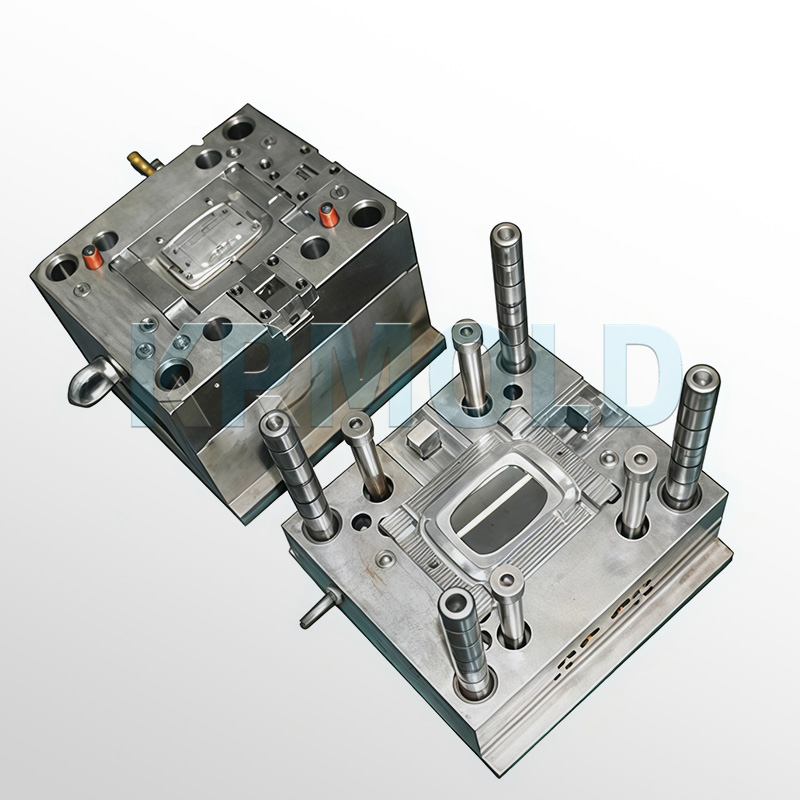

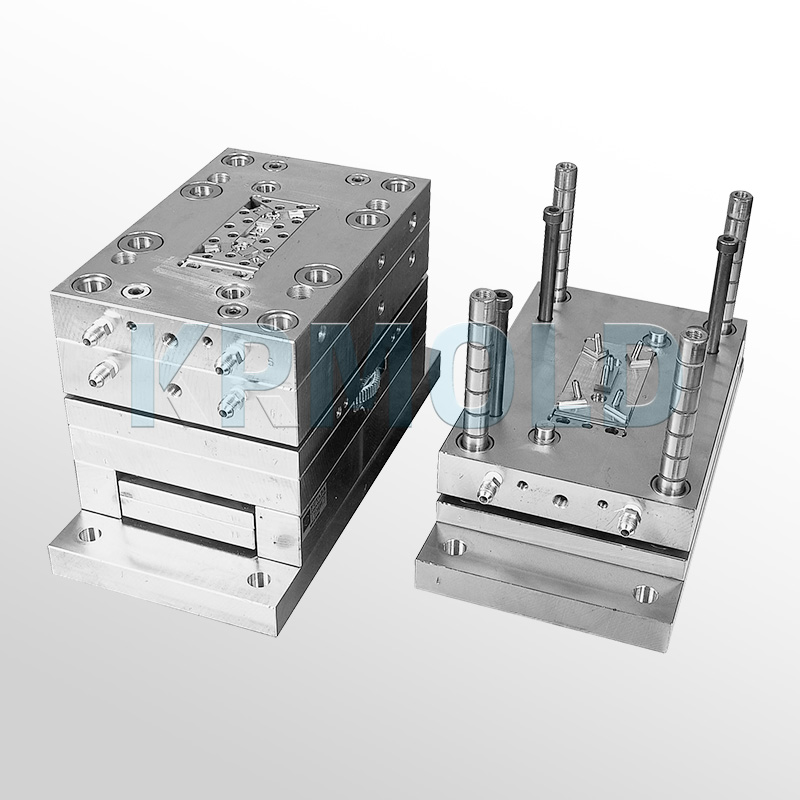

●Assembly for plastic auto parts sensor mold

The final step in auto sensor parts mold making is assembly, including the configuration of guides, ejectors, water channels, and hot runners (if applicable). This step ensures that all plastic auto parts sensor mold components work in coordination to improve the efficiency and stability of the injection molding operation.

Step 3: Testing and validation for auto sensor parts mold

●T0/T1 testing for auto sensor parts mold

After plastic auto parts sensor mold completion, conducting T0/T1 testing is essential. This stage primarily involves determining the process window and evaluating the dimensions and appearance of the parts. These tests help identify potential problems in the auto sensor parts mold design and manufacturing process, allowing for adjustments before mass production.

●Auto sensor parts mold inspection

During the testing phase, CMMs and optical measurements are used to precisely inspect each component of the plastic auto parts sensor mold. Each part needs to be confirmed to meet design requirements, providing a "gold standard" for subsequent production.

●Auto sensor parts mold optimization

Based on the initial testing, further plastic auto parts sensor mold optimization may be necessary, such as adjusting the gate location, optimizing venting, improving cooling balance, and adjusting steel for safety. These improvements contribute to increasing auto sensor parts mold production efficiency and stability.

Step 4: Auto sensor parts mold mass production

●Stable operation

After the plastic auto parts sensor mold enters mass production, its repeatability under key parameters such as temperature, pressure, and time must be ensured. A stable production process is fundamental to ensuring the quality of every part meets standards.

●Auto sensor parts mold quality control

Quality control is crucial for ensuring consistent quality in the mass production of plastic auto parts sensor molds. First article inspection and statistical process control are commonly used methods to promptly identify and correct deviations in production, ensuring the quality of the final product. Final inspection is also essential. A rigorous inspection process ensures that every delivered product meets standards.

●Auto sensor parts mold maintenance

Plastic auto parts sensor molds experience wear and tear during production, making regular maintenance crucial. Regular cleaning, lubrication changes, water pipe cleaning, and proper spare parts management are necessary to ensure long-term stable auto sensor parts mold operation.

02/Understanding Plastic Auto Parts Sensor Mold Components

Auto sensor parts molds consist of various components that utilize injection, blow molding, compression, transfer, and rotational molding to transform thermoplastic or thermosetting materials into the final product. The core structure of the plastic auto parts sensor mold includes the cavity and the core. Liquid plastic completes a full injection molding cycle through injection, cooling, solidification, and ejection.

In this process, the quality and design details of the auto sensor parts mold (such as the layout of the gating system and the configuration of cooling channels) directly affect the quality of the parts. Mastering these technical details can further improve the production efficiency and product quality of plastic auto parts sensor molds.