KINGREAL UNIVERSAL IND., LTD

Phone

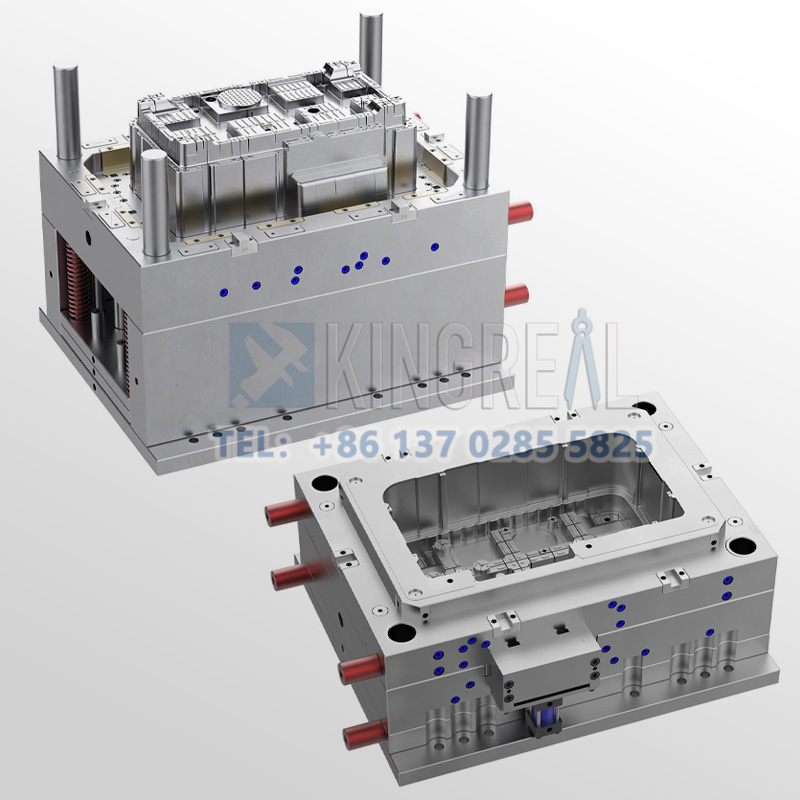

+86-13702855825Storage Boxes Injection Molds are crucial equipment in the plastic storage boxes injection molding process and are responsible for the molding of plastic products. Since functional accessories injection mold processing plants produce a large number of plastic products every day, these plastic storage boxes injection molds must withstand the dual test of high temperature and high pressure. Therefore, correct maintenance and care are particularly important.

Good mold maintenance can not only extend the service life of the storage boxes injection mold, but also reduce the production cost of the enterprise and improve production efficiency. In this article, KINGREAL MOLD will discuss in detail with you the maintenance methods of functional accessories injection molds.

| 1 | Importance of Storage Boxes Injection Mold Maintenance |

| 2 | Daily Maintenance of Storage Boxes Injection Molds |

| 3 | Production and Maintenance of Storage Boxes Injection Molds |

| 4 | Maintenance Cycle of Storage Boxes Injection Molds |

| 5 | Management System of Injection Molds |

| 6 | Plastic Storage Boxes Injection Mold Operation Suggestions |

1. Importance of Storage Boxes Injection Mold Maintenance

Plastic storage boxes injection molding machine molds are key equipment for the production of plastic products. Their complexity and sophistication require proper maintenance during use. The functional accessories injection mold is under great injection pressure during the production process. If it is not maintained in a timely and effective manner, it may cause mold wear, deformation or even damage, thereby affecting the quality and production efficiency of the product. Through reasonable maintenance, you can:

- Extend the service life of the mold: Regular maintenance can effectively reduce wear and corrosion and extend the service life of the storage boxes injection mold.

- Improve production efficiency: A good plastic storage boxes injection mold condition can ensure the smooth progress of the production process and reduce downtime.

- Reduce production costs: Extending the service life of the storage boxes injection mold and improving production efficiency can significantly reduce the production costs of the enterprise.

2. Daily Maintenance of Storage Boxes Injection Molds

(1) Regular cleaning

After each use, the residual plastic, oil and dust on the plastic storage boxes injection mold surface should be removed in time. Use a special mold cleaner and soft cloth to wipe, and avoid using hard tools to scratch the mold surface to prevent damage. For some small gaps and corners, compressed air can be used to blow away dust and debris.

(2) Lubrication and maintenance

Regularly add an appropriate amount of lubricating oil or grease to the moving parts of the storage boxes injection mold to reduce friction and wear. The choice of lubricating oil should be determined according to the material and working environment of the plastic storage boxes injection mold. For example, the ejector, slider and other parts need to be regularly added with suitable lubricants to ensure smooth movement.

(3) Check the cooling system

The cooling system of the functional accessories injection mold is crucial to the molding quality and production efficiency of the product. Regularly check whether the cooling pipe is unobstructed, whether there is water leakage, and clean the scale and impurities in the pipe in time.

(4) Check mold parts

Regularly check various parts of the storage boxes injection mold, such as core, cavity, insert, etc., to check for wear, deformation, cracks, etc. If a problem part is found, it should be replaced or repaired in time to ensure the normal operation of the functional accessories injection mold.

(5) Anti-rust treatment

If the storage boxes injection mold is not used for a long time, it should be treated with anti-rust. Anti-rust oil can be applied to the surface of the plastic storage boxes injection mold, and the mold can be stored in a dry and ventilated environment, which can effectively prevent the functional accessories injection mold from rusting and extend its service life.

3. Production and Maintenance of Storage Boxes Injection Molds

(1) Maintenance during production

During the functional accessories injection molding process, the molten material is injected into the mold for molding, and the mold needs to withstand a considerable amount of injection pressure. Therefore, reasonable adjustment of injection pressure, injection speed, clamping force and effective distance of the pull rod are all effective ways to reduce mold loss.

- Temperature control: Keep the plastic storage boxes injection mold working at normal temperature to avoid damage to the storage boxes injection mold caused by too high or too low temperature.

- Check for foreign matter: Before the functional accessories injection mold is locked, check whether there is foreign matter or residual products in the cavity, and clean them in time to avoid affecting the locking and use of the plastic storage boxes injection mold.

(2) Maintenance after production

After the storage boxes injection mold is used, it should be closed immediately to prevent moist air from contacting the cavity and core, causing rust. Anti-rust oil or mold release agent can be applied to the core and cavity to prevent the mold from rusting and corrosion due to long-term non-use. When using it again, the applied anti-rust oil needs to be wiped clean to avoid affecting production.

4. Maintenance Cycle of Storage Boxes Injection Molds

The maintenance cycle of functional accessories injection molds depends on factors such as the frequency of use of the plastic storage boxes injection mold, the production environment, and the plastic materials processed. It is generally recommended to perform maintenance according to the following cycles:

(1) Daily maintenance

After the production is completed every day, perform simple cleaning and inspection to ensure that the functional accessories injection mold is in good condition.

(2) Regular maintenance

- Minor maintenance: Perform a more comprehensive maintenance every 5,000 to 10,000 productions, including cleaning, lubrication, and inspection of parts.

- Major maintenance: Disassemble the storage boxes injection mold every 20,000 to 50,000 productions, thoroughly clean, inspect and repair, and replace severely worn parts.

5. Management System of Injection Molds

Establishing a mold management system is an important part of mold maintenance for enterprises. Since the functional accessories injection molds required for different plastic products are different, manufacturers should establish a mold management library and hire special workers to regularly inspect and maintain them.

(1) Mold file management

Establish detailed files for each storage boxes injection mold, including mold usage records, maintenance records, fault records, etc. This can help companies better manage plastic storage boxes injection molds and discover potential problems in a timely manner.

(2) Mold library management

Establish a special mold library and establish a computer management system for storage boxes injection molds. The mold library should be located in a place with low humidity and good ventilation, and the temperature should be kept below 70%. If the humidity exceeds 70%, the mold is prone to rust. The mold should be stored on a shelf and pay attention to corrosion and dust prevention.

(3) Shift handover system

When the operator takes over the shift, in addition to handing over the production records, he should also explain the use of the mold in detail to ensure the timely transmission of information.

6. Plastic Storage Boxes Injection Mold Operation Suggestions

(1) Choose the right molding equipment

It is crucial to choose the right injection machine. If the storage boxes injection molding machine is too small, it cannot meet production needs; if it is too large, it will waste energy. In addition, improper clamping force adjustment may damage the plastic storage boxes injection mold.

(2) Empty mold operation

After the mold is installed on the plastic storage boxes injection molding machine, first perform empty mold operation to observe whether the operation of each part is flexible and whether there are any abnormalities, and ensure that the ejection stroke and opening stroke are in place.

(3) Temperature management

Keeping the storage boxes injection mold operating at normal working temperature can effectively extend the service life of the functional accessories injection mold.

(4) Timely cleaning

Before each clamping, check whether the cavity is cleaned and no residual products or foreign matter are left to avoid affecting subsequent production.