KINGREAL UNIVERSAL IND., LTD

Phone

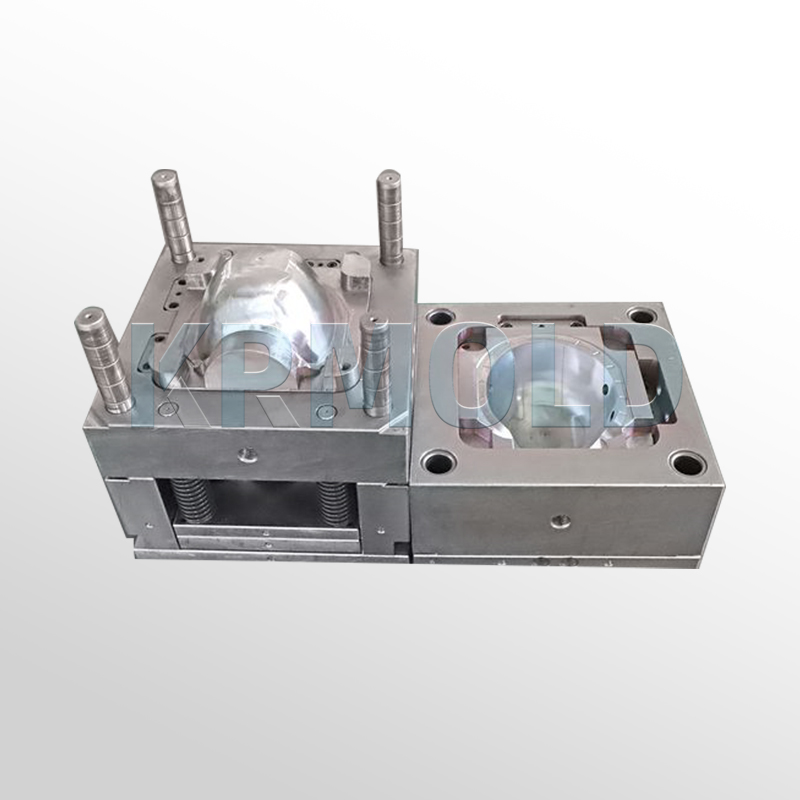

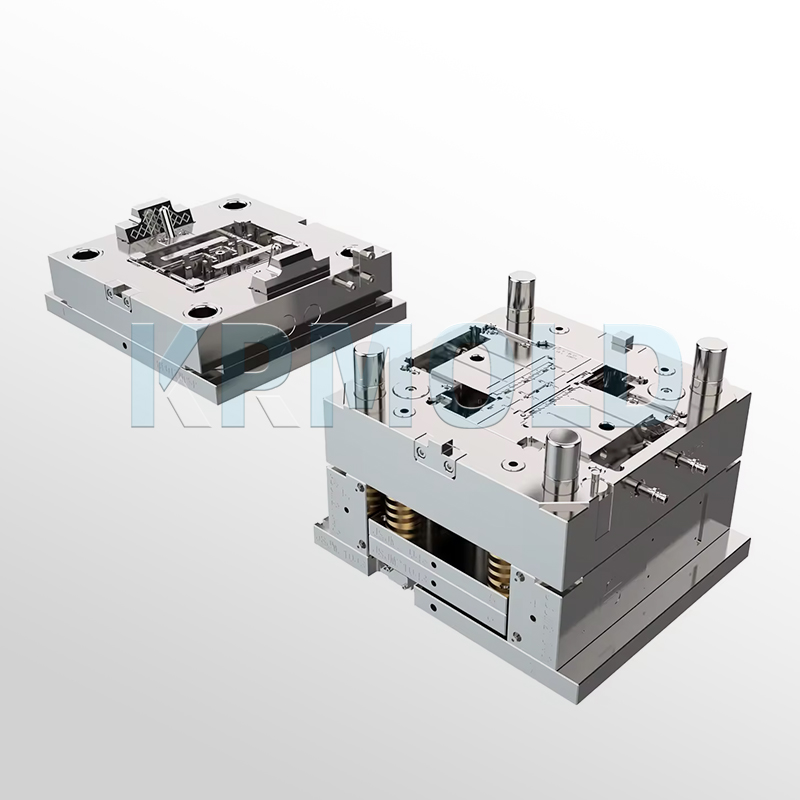

+86-13702855825PPE injection molds are key equipment for producing plastic products, especially in the process of PPE injection molding, where they play an indispensable role. Factories produce thousands of plastic products every day, and these products are mainly molded by mold processing and PPE injection molding. Since PPE injection molds are a set of complex and delicate equipment, they need to withstand the dual test of pressure and temperature. Therefore, proper and correct maintenance can extend the service life of the PPE injection molds, reduce the production cost of the enterprise, and improve the utilization rate. This article will discuss in detail how to maintain PPE injection molds to extend their service life and improve production efficiency. |  |

| 1 | Maintenance of Molds in PPE Injection Molding Machine Production |

| 2 | Maintenance of PPE Injection Molding Machine Molds After Production |

| 3 | Establishing a Maintenance System for PPE Injection Molding Machine Molds |

| 4 | Precautions |

| 5 | Maintenance Cycle of PPE Injection Molds |

| 6 | Importance of PPE Injection Molds Maintenance |

| 7 | Classification of PPE Injection Molds Maintenance |

1. Maintenance of Molds in PPE Injection Molding Machine Production

In the process of PPE injection molding, the molten material is injected into the mold to be molded and finally the finished product is made. Therefore, the mold needs to withstand a fairly high injection pressure every day. In order to reduce the loss of the PPE injection molds, it is effective to reasonably adjust the injection pressure, injection speed, clamping force, and the effective distance of the tie rod.

1.1 Temperature control

When using PPE injection molds, the working temperature of the mold must be reasonably controlled. Too high or too low temperature will damage the mold and affect the quality of PPE injection molding. Therefore, it is crucial to keep the mold within the normal working temperature range.

1.2 Regular inspection

At the same time, always observe the dynamics of mold use. If any abnormality is found, the machine should be stopped immediately for a comprehensive investigation. Especially before the mold is locked, it is necessary to carefully check whether there are any foreign objects in the cavity that have not been removed, especially the residual products. If any foreign objects are found, they should be cleaned in time to avoid affecting the locking or even damaging the PPE injection molds.

2. Maintenance of PPE Injection Molding Machine Molds After Production

After the mold is used, it should be closed to prevent humid air from contacting the cavity and core, causing rust. Anti-rust oil or mold release agent can be applied to the core and cavity to prevent the PPE injection molds from rusting and corrosion due to long-term non-use.

2.1 Cleaning and rust prevention

When using it again, wipe off the anti-rust oil and other substances applied to avoid affecting the subsequent PPE injection molding. In addition, the cavity and core need to be cleaned regularly to avoid corrosion caused by residual products.

2.2 Maintenance of cooling water channels

If the mold is not used for a long time, the residual water in the cooling water channel should be removed in time. At the same time, compressed air can be used to blow anti-rust oil into various parts of the pipeline to extend the service life of the cooling water pipe and ensure that the next PPE injection molding can proceed smoothly.

3.Establishing a Maintenance System for PPE Injection Molding Machine Molds

Since different plastic products require different plastic injection molds, in order to better manage many molds, manufacturers should establish a mold management library and hire special workers to regularly inspect and maintain the molds. This not only helps to standardize management, but also improves production efficiency.

4. Precautions

When maintaining PPE injection molds, be sure to wear labor protection supplies to ensure safety. For heavy objects, a crane must be used for operation. It is strictly forbidden to lift the mold directly with your hands to prevent injury to the limbs.

4.1 Anti-rust measures

Rust-proof measures for molds are necessary. After maintenance, special attention should be paid to the anti-rust action of the mold, and the remaining water inside the waterway should be blown dry with an air gun to avoid rust.

4.2 Use of lubricating oil

Adding too much lubricating oil does not bring better lubrication effect, so it should be used in moderation. Excessive lubricating oil may cause the mold surface to become sticky, affecting the quality of PPE injection molding.

4.3 Installation precautions

After the mold maintenance is completed, pay special attention to the number and direction of the inserts and other parts during installation to ensure that they are not installed upside down or incorrectly.

In addition, it is necessary to check whether each screw is fully tightened, and the screws should be tightened diagonally when installing to ensure the stability of the PPE injection molds.

5. Maintenance Cycle of PPE Injection Molds

The maintenance cycle of PPE injection molds depends on factors such as the frequency of use of the mold, the production environment, and the processed plastic materials. Generally speaking, it is recommended to perform maintenance according to the following cycles:

5.1 Daily maintenance

After the production is completed every day, simple cleaning and inspection should be carried out to ensure the normal operation of the mold.

5.2 Regular maintenance

Minor maintenance: For every 5,000-10,000 productions, a more comprehensive maintenance is carried out, including cleaning, lubrication, and inspection of parts.

Major maintenance: For every 20,000-50,000 productions, the mold is disassembled, thoroughly cleaned, inspected, and repaired, and severely worn parts are replaced.

6. Importance of PPE Injection Molds Maintenance

6.1 Maintaining the normal operation of the mold

Regular maintenance can maintain the normal operation of the mold, reduce unnecessary wear of the active parts, and thus extend the service life of the PPE injection molds.

6.2 Improving production efficiency

Through reasonable maintenance measures, the oil pollution in production can be significantly reduced, the production environment can be kept clean, and the efficiency and quality of PPE injection molding can be improved.

6.3 Reducing production costs

Mold maintenance can not only reduce the losses caused by wear, but also reduce the downtime caused by mold failure, thereby reducing the overall production cost of the enterprise.

7. Classification of PPE Injection Molds Maintenance

PPE injection molds maintenance can be mainly divided into the following three categories:

Daily maintenance: including cleaning, lubrication and checking the operating status to ensure that the mold operates under normal conditions.

Regular maintenance: formulate a detailed maintenance plan according to the production frequency for more comprehensive maintenance.

Appearance maintenance: regularly clean the mold surface to keep its appearance clean and reduce the erosion of the external environment on the PPE injection molds.

Maintenance of PPE injection molds is an important part of ensuring the smooth production of plastic products. Through reasonable maintenance measures, the service life of the PPE injection molds can be extended, production efficiency can be improved, and enterprise costs can be reduced.

If you have further interest in PPE injection molding or PPE injection molds maintenance or need more information, please consult KRMOLD. Only through scientific maintenance can the PPE injection molds be maximized and create greater value for the enterprise.