KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Factors to Consider When Manufacturing Plastic Car Side Mirror Injection Mould |

| 2 | Stages of Plastic Car Side Mirror Injection Mould Manufacturing |

| 3 | Benefits of Using Automobile Side Mirror Injection Mould |

In the modern automotive industry, plastic car side mirrors play an indispensable role as a crucial component. To ensure the quality and performance of side mirrors, manufacturing high-precision plastic car side mirror injection mould is essential. KRMOLD, as a professional manufacturer of automobile side mirror injection mould, is committed to developing customized plastic car side mirror injection mould solutions based on customers' actual needs. This article will detail the manufacturing process of automobile side mirror injection mould, including design, material selection, and testing.

1. Factors to Consider When Manufacturing Plastic Car Side Mirror Injection Mould

Several key factors need to be considered during the manufacturing of automobile side mirror injection mould.

1.1 Material selection for plastic car side mirror injection mould

Choosing the appropriate material is the first step in manufacturing automobile side mirror injection mould. KRMOLD engineers typically choose high-temperature resistant, high-strength alloy materials because the plastic car side mirror injection mould needs to withstand the high temperatures and pressures of the plastic during injection molding. Common mold materials include aluminum alloys and steel, with steel being widely used in molds for mass production due to its higher wear resistance and strength.

1.2 Automobile side mirror injection mould design

Plastic car side mirror injection mould design is one of the most crucial steps in the injection molding process. KRMOLD engineers carefully consider the parting line, runner, and gate design. A well-designed automobile side mirror injection mould ensures uniform plastic flow within the plastic car side mirror injection mould, preventing porosity and defective products. Improper design can lead to plastic car side mirror injection mould scrapping and increased production costs. Furthermore, the automobile side mirror injection mould' separation mechanism must be properly designed to allow for easy removal of the finished product after cooling.

1.3 Plastic car side mirror injection mould strength

Automobile side mirror injection mould strength is a key factor affecting its lifespan and production efficiency. KRMOLD engineers ensure the plastic car side mirror injection mould structure can withstand the pressure applied during plastic injection while also considering its wear resistance over long-term use. Proper design and material selection effectively extend automobile side mirror injection mould life and reduce production costs.

2. Stages of Plastic Car Side Mirror Injection Mould Manufacturing

The process of manufacturing automobile side mirror injection mould can be divided into several stages, each crucial.

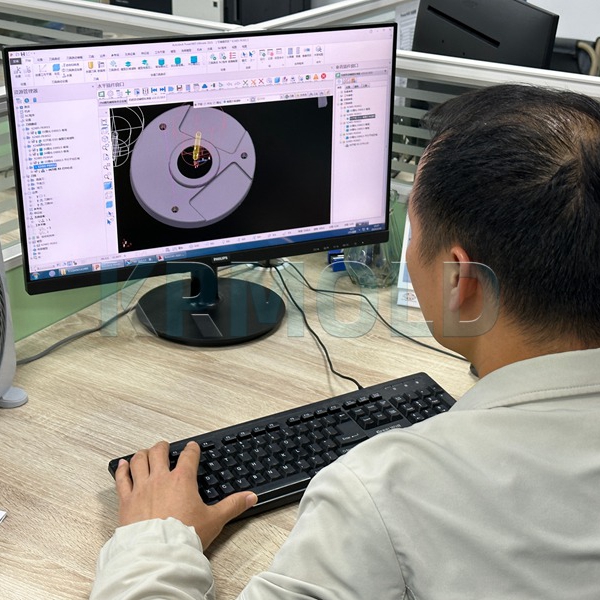

2.1 Importance of plastic car side mirror injection mould design

Automobile side mirror injection mould design is the first and most expensive step in injection mold manufacturing. KRMOLD engineers typically use advanced CAD software for 3D modeling to ensure design accuracy. The design process considers various factors, including the product's appearance, function, and manufacturing process. A well-designed plastic car side mirror injection mould not only improves production efficiency but also reduces defect rates, ensuring the quality of the final product.

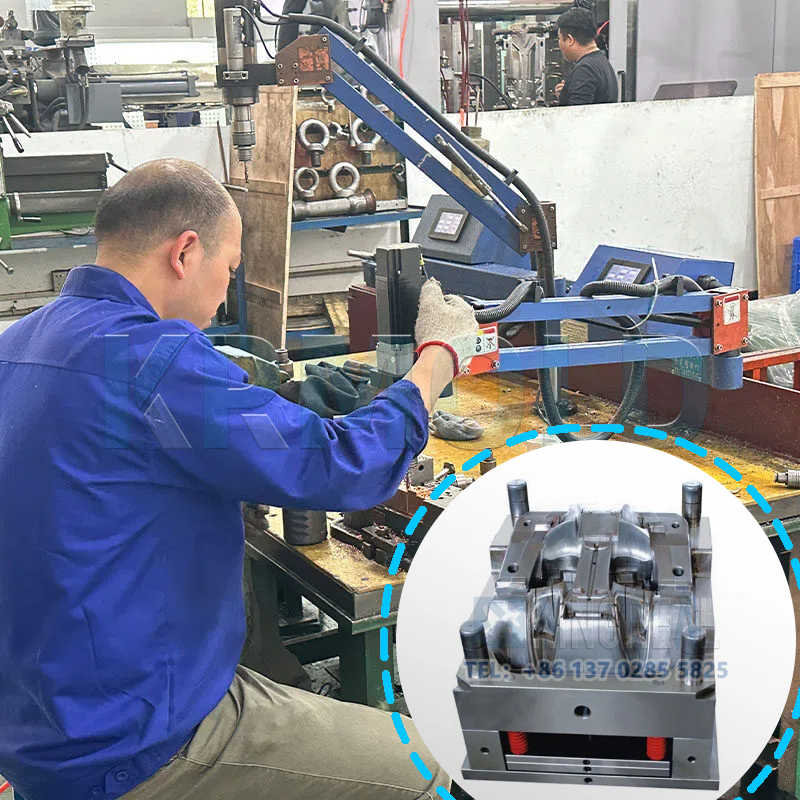

2.2 Automobile side mirror injection mould manufacturing process

The plastic car side mirror injection mould manufacturing process begins with the creation of a 3D model. KRMOLD engineers create a corresponding mold base plate based on the customer's product requirements. This base plate is then used to manufacture the mold body, ultimately forming the automobile side mirror injection mould. During manufacturing, engineers conduct multiple inspections and adjustments to ensure the plastic car side mirror injection mould’ precision and stability.

2.3 Automobile side mirror injection mould testing

After creating the plastic car side mirror injection mould, testing is an essential step. KRMOLD engineers employ various testing methods to ensure the automobile side mirror injection mould' performance meets customer requirements. Pressure testing is a common method; engineers fill the plastic car side mirror injection mould with liquid and measure the pressure required to induce fracture in the part. This process helps determine the automobile side mirror injection mould' maximum load capacity and durability. Simultaneously, fitting tests using prototype parts are an essential step to ensure the plastic car side mirror injection mould can successfully produce standard-compliant plastic car side mirrors.

3. Benefits of Using Automobile Side Mirror Injection Mould

Using injection molds for plastic car side mirrors offers numerous significant advantages.

3.1 Cost-effectiveness

The KRMOLD team can manufacture any number of plastic car side mirror injection mould according to customer needs, significantly reducing production costs. Compared to traditional manufacturing processes, injection molding can produce a large number of parts in a short time, making it particularly suitable for large-scale production needs.

3.2 Production efficiency

Injection molding is a fast and efficient production method. By injecting molten plastic into a automobile side mirror injection mould, which then cools, a molded product is obtained—a process that typically takes only a few minutes. For plastic car side mirrors requiring mass production, this efficient production method can significantly improve production efficiency and shorten delivery time.

3.3 Customization capabilities

KRMOLD plastic car side mirror injection mould solutions offer strong customization capabilities. Customers can control the shape, size, and design of each automobile side mirror injection mould according to their own needs. This flexibility not only meets the needs of different car models but also adapts to the challenges brought about by market changes. In the highly competitive automotive market, the ability to quickly adjust production lines to meet customer needs is crucial.

Contact KRMOLD for more information about plastic car side mirror injection mould.