KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content

1. KRMOLD Car Door Handle Injection Mold Design Details

2. Heat Treatment and Surface Treatment of Car Door Handle Injection Mold Parts

3. Car Door Handle Injection Mold Trial and Improvement

4. Characteristics and Material Selection of Automotive Door Handles

Essential in the creation and manufacture of automotive door handle injection molds is design. KRMOLD has great experience and professional technology that allows it to offer tailored car door handle injection mold design services as the design and performance of car door handles immediately affects the general quality of a vehicle. This essay will describe the processes KRMOLD follows when creating automotive door handle injection molds, therefore enabling readers to have more thorough knowledge of the technology and specifications behind the design.

1. KRMOLD Car Door Handle Injection Mold Design Details

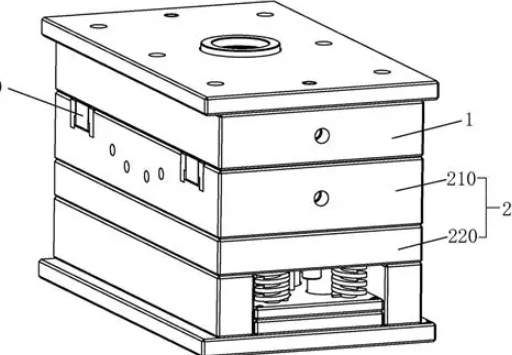

When designing automotive door handle injection molds, material selection and mold structure analysis are paramount. Typically, PC/ABS is chosen as the material for car door handles. This material not only possesses excellent mechanical properties but is also highly suitable for electroplating. Furthermore, PC/ABS has a shrinkage rate of 1.005%, making it suitable for high-precision injection molding.

1.1 Preliminary analysis and feasibility study for car door handle injection mold

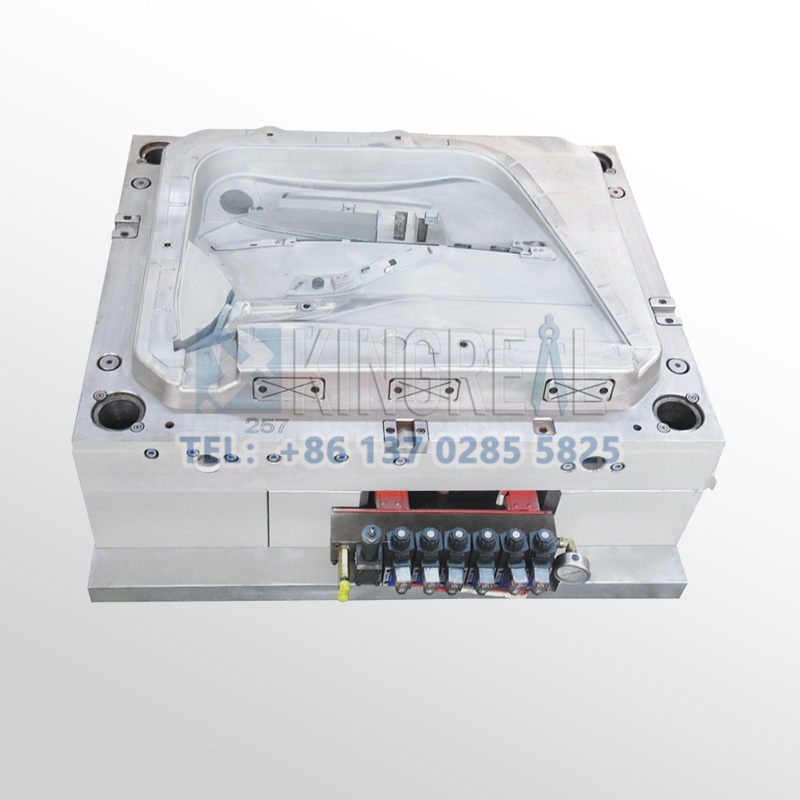

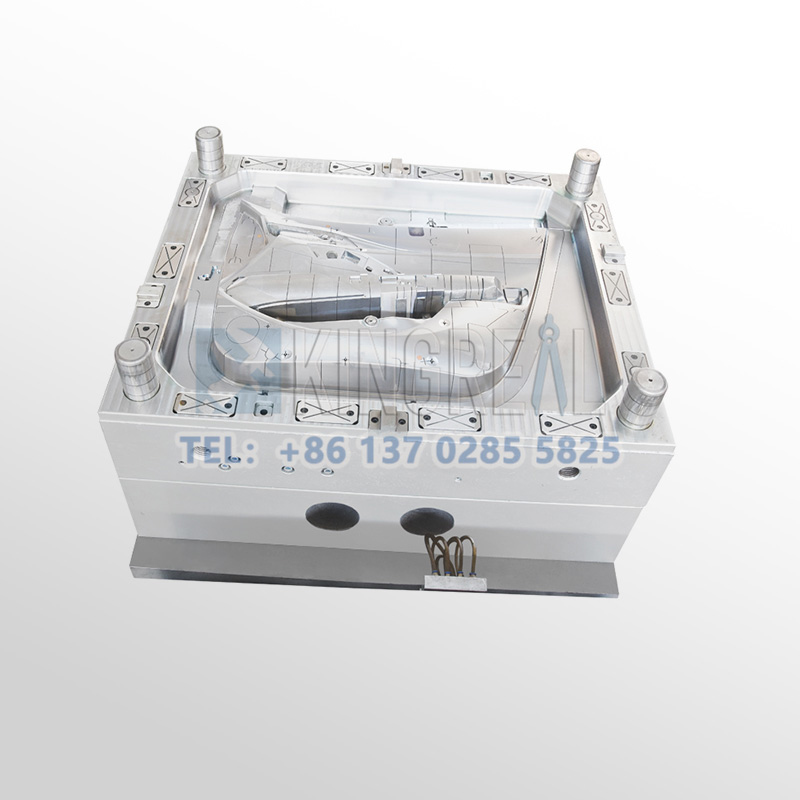

KRMOLD design team first conducts a detailed analysis of the car door handle's shape, taking into account the customer's specific requirements and fully considering both functionality and aesthetics. At this stage, a feasibility analysis of the automotive door handle injection mold structure is performed to ensure that the designed car door handle injection mold meets production needs.

1.2 Determining key car door handle injection mold parameters

Based on customer requirements, KRMOLD determines the type of steel used, the number of mold cavities, and whether a hot runner system is employed. Given that each car typically has four door handles, the KRMOLD design team favors multi-cavity designs to improve production efficiency. For example, a common design is a four-cavity mold. This design not only improves production efficiency but also reduces the production cost per door handle to some extent.

1.3 Cooling system design for car door handle injection mold

The molding temperature of automotive door handle materials is typically high; therefore, designing an efficient cooling system is crucial. Pipe fittings, plugs, pipes, and seals make up some of the parts of the cooling system. A good cooling channel guarantees the automotive door handle injection mold maintains an appropriate temperature during injection molding, hence enabling quick cooling and boosting manufacturing efficiency.

2. Heat Treatment and Surface Treatment of Car Door Handle Injection Mold Parts

KRMOLD mostly produces main parts including fixed mold inserts, moving mold inserts, and inclined slides from S136 steel to guarantee dimensional correctness and surface quality of car door handle injection mold parts. Following heat treatment, these components usually have a hardness ranging from 50 to 54 HRC, hence guaranteeing enough wear resistance and strength during manufacture. Surface finish is improved and corrosion resistance is increased by means of surface coating.

KRMOLD chooses steels like 718 or H13 based on the real usage frequency of the automotive door handle injection mold and conducts appropriate heat treatment to guarantee the car door handle injection mold has both reasonable economy and function for general structural components such sliders and side cores.

3. Car Door Handle Injection Mold Trial and Improvement

After the design is completed, the automotive door handle injection mold enters the trial molding stage. For car door handle injection molds with high requirements for dimensions and appearance, strict control is needed at this stage. KRMOLD uses mold flow analysis to predict key factors such as shrinkage control, demolding angle, and gate location in advance. However, the automotive door handle injection mold's venting setup, overflow groove setup, and car door handle injection mold temperature control still need continuous adjustment during the trial molding process.

3.1 Shrinkage control and parameter adjustment

According to the material characteristics, KRMOLD designers carefully fine-tune the injection molding parameters during the test molding process to guarantee the finished product fulfills consumer needs. Controlling several variables including injection speed, pressure, and cooling time allows one to maximize every aspect of the automotive door handle injection mold to get the best molding outcomes.

3.2 Car door handle injection mold improvement feedback

Critical is the feedback received throughout the trial molding phase. Based on the trial molding results, KRMOLD modifies the automotive door handle injection mold design as needed. Achieving high-quality automobile door handles depends on this process, which guarantees that every car door handle injection mold fulfills the anticipated performance and appearance criteria.

4. Characteristics and Material Selection of Automotive Door Handles

After injection molding, the inner door handles of automotive door locks typically require electroplating or painting to enhance their appearance, increase aesthetics, and improve durability. This not only improves the fit between the door handle and the body and interior/exterior trim but also makes customer requirements for the finished product more stringent. Therefore, higher demands are placed on the materials used and the molding quality of automotive door handles.

4.1 Door handle shape and materials

Automotive door handles typically come in two shapes: elongated and snap-fit. Elongated door handles are more favored by most automotive OEMs. However, the slender design of elongated door handles makes them more susceptible to damage compared to snap-on handles, making material selection particularly important. Elongated door handles often utilize higher-strength materials, such as electroplated PA, while snap-on handles may opt for materials with lower strength requirements, such as electroplated PC/ABS.

4.2 Challenges and solutions in car door handle injection mold design

The biggest challenge in designing automotive door handle injection molds is achieving efficient production while maintaining strength and aesthetics. To address this, KRMOLD deconstructs the design process in the early stages of car door handle injection mold making to minimize potential defects such as porosity and weld seams, ensuring a smooth and standard-compliant final molded part surface.

If you have any questions about automotive door handle injection molds or related technologies, please feel free to contact KRMOLD!