KINGREAL UNIVERSAL IND., LTD

Phone

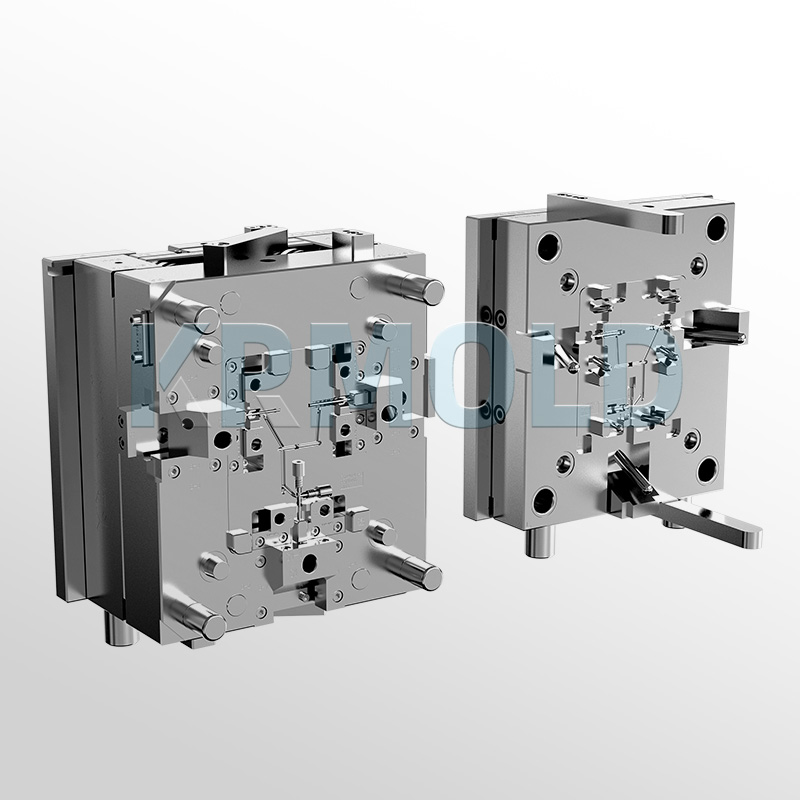

+86-13702855825Silicone rubber injection molds are an indispensable and important tool in the production process of plastic products, especially in the silicone rubber injection molding process, where their dimensional accuracy and shape accuracy directly affect the quality and accuracy of the final product. In order to ensure that the silicone rubber injection molds manufactured by silicone rubber injection molding meet the design requirements, the dimensional accuracy and shape accuracy must be strictly controlled. In this article, KRMOLD will introduce to you the control methods of dimensional accuracy and shape accuracy of silicone rubber injection molds in the silicone rubber injection molding process, including considerations in the design stage, selection of processing technology, and means of quality inspection. |  |

| 1 | Considerations in the Design Stage |

| 2 | Selection of Processing Technology |

| 3 | Quality Inspection Methods |

| 4 | Material Selection |

| 5 | Control of Temperature and Humidity |

1. Considerations in the Design Stage

1.1Reasonable design tolerance In the silicone rubber injection molds design stage, it is crucial to reasonably determine the tolerance range of the mold. While bearing in mind elements including the shrinkage rate of the material, the constraints of the processing technique, and the functional needs of the product, this process should be founded on the specifications of the product and its use environment. The qualities of the material, particularly the shrinkage rate, will directly influence the size of the finished item in the silicone rubber injection molding process. So, during the design, careful consideration should be given to these elements to guarantee that the silicone rubber injection molds will create products that satisfy the requirements after the silicone rubber injection molding is finished.

1.2 Avoid dimension stacking In silicone rubber injection molds design, dimension stacking should be avoided as much as possible, that is, multiple dimensions share a tool or tooling, which may cause the change of one dimension to affect the accuracy of other dimensions. Especially in complex mold design, avoiding dimension stacking can significantly reduce quality problems caused by errors and improve the stability and consistency of silicone rubber injection molding. |  |

2. Selection of Processing Technology

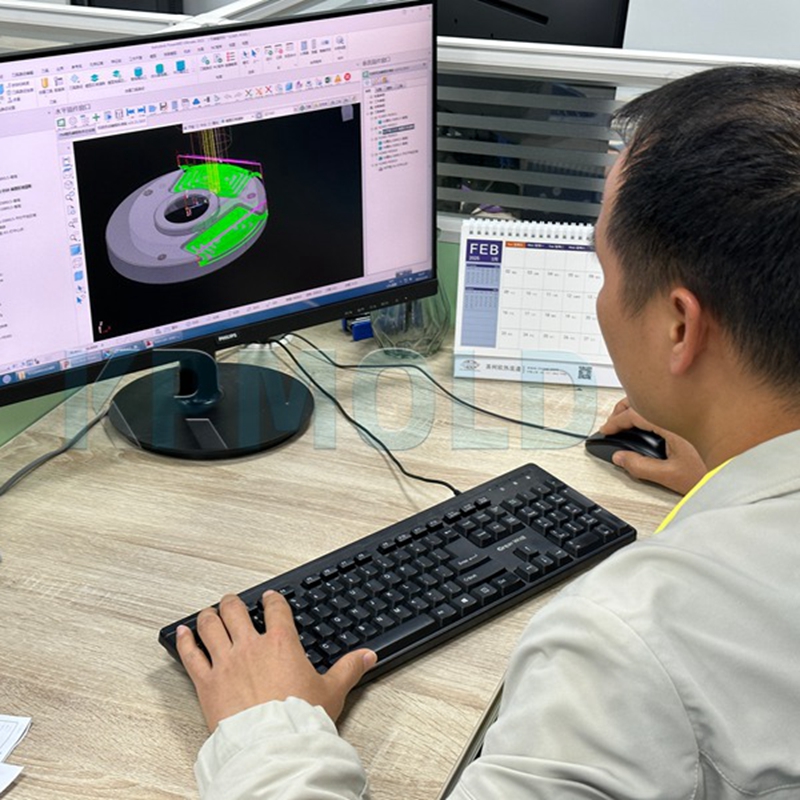

2.1 Select appropriate processing equipment Selecting high-precision processing equipment is the basis for ensuring the accuracy of mold size and shape. Higher processing precision and stability, for instance, can come from CNC machining centers and wire cutting machines. The smoothness of the silicone rubber injection molding procedure directly correlates with the precision of the silicone rubber injection molds. Correct processing tools will greatly cut mistakes and boost productivity efficiency.

2.2 Select appropriate processing technology Choosing the right processing method depends on the various form of silicone rubber injection molds and material characteristics. Higher size and shape accuracy can be obtained, for instance, by techniques like EDM and wire cutting as well as precision grinding. During the silicone rubber injection molding, excellent mold processing techniques can greatly enhance the surface quality and detail performance of plastic goods, therefore guaranteeing that the ultimate product satisfies the design criteria.

2.3 Control processing parameters Strict management of processing parameters including cutting speed, feed speed and tool wear during the cutting operation can greatly lower the frequency of mistakes and boost processing precision. Reasonable processing parameters directly influence the efficiency of silicone rubber injection molding and the quality of the finished product in addition to impacting the dimensional precision of the silicone rubber injection molds. By carefully regulating these factors, it can be guaranteed that the results of every silicone rubber injection molding will be steady within the anticipated range. |  |

3. Quality Inspection Methods

3.1 Use measuring tools To properly assess the dimensions of thesilicone rubber injection molds throughout the manufacturing process, it is absolutely vital to use precision measuring tools including micrometers, vernier calipers, and picture measuring instruments. The measuring data show that the silicone rubber injection mold is modified and repaired on time to maintain its dimensional precision and form accuracy. Regular quality inspections can help businesses find possible issues and guarantee that the silicone rubber injection molds is continually in the best shape, hence increasing product quality and manufacturing efficiency in the silicone rubber injection molding process.

3.2 Establish a quality control system Ensuring silicone rubber injection molds' manufacturing accuracy depends on setting a good quality control system. Formulating standard process flows, assigning acceptable inspection frequencies, and developing corrective actions should be part of this system. The manufacturing accuracy and stability of the silicone rubber injection mold can be greatly enhanced by means of regular quality inspection and improvement programs, guaranteeing that every injection molded item can meet high requirements. 3.3 Use non-contact detection methods Employing non-contact detection techniques like optical measurement or 3D scanners, the shape and size data of the silicone rubber injection molds can be rapidly and precisely acquired and matched against the design requirements. Because it can swiftly spot possible quality issues without impacting the silicone rubber injection mold, this approach is especially important in the quality control of silicone rubber injection molding. |  |

4. Material Selection

4.1 Choose materials with good stability Choosing mold materials with good stability and low shrinkage can reduce the size and shape errors caused by material deformation. Commonly used mold materials include tool steel and cemented carbide. When performing injection molding, the choice of materials has a direct impact on the durability and molding effect of the mold. High-quality materials can improve the service life and molding accuracy of the mold.

4.2 Control the processing and heat treatment of materials Precise processing and heat treatment of mold materials lowers the internal stress and distortion of the material, hence increasing the size and form precision of the mold. The heat treatment procedure of the silicone rubber injection molds will directly influence its performance during the silicone rubber injection molding process; hence, particular care should be given to the material's heat treatment approach to guarantee that the silicone rubber injection mold may work reliably in a high temperature surroundings. |  |

5. Control of Temperature and Humidity

5.1 Control the processing environment temperature During the processing process, the temperature of the processing environment should be controlled to avoid the impact of temperature changes on the size and shape of the silicone rubber injection molds. Constant temperature equipment and temperature control systems can be used to maintain a stable temperature in the processing environment. Temperature control is also important during the silicone rubber injection molding process, because temperature changes during silicone rubber injection molding will affect the fluidity and molding effect of the plastic.

5.2 Avoid humidity changes To prevent humidity variations affecting the shape and size of the silicone rubber injection mold, the silicone rubber injection molds should be kept in a dry, well-ventilated environment. The storage area's humidity can be managed using dehumidifiers or humidity control tools. This is especially important in silicone rubber injection molding since variations in humidity may influence the performance of plastic items and thereby influence the quality of the finished product. |  |