KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Influence of Material Selection |

| 2 | Optimization of Process Parameters |

| 3 | Optimization of Mold Design |

| 4 | Control of Production Environment |

| 5 | Quality Inspection and Control |

| 6 | Case Analysis |

| 7 | Future Development Trends of Insert Molding |

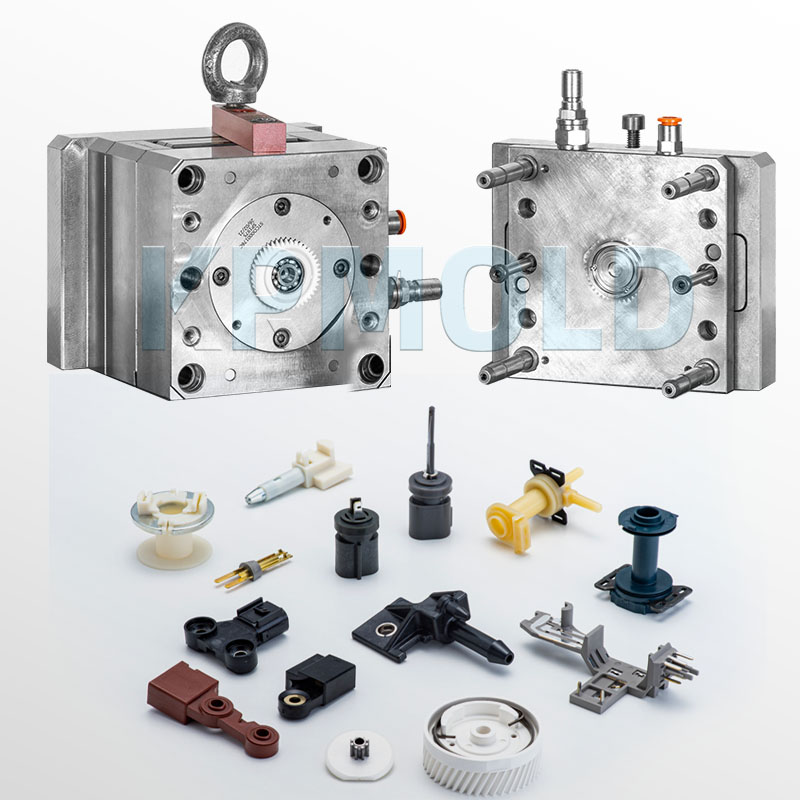

Among the most often used plastic injection molding techniques in modern manufacturing is insert injection molding. Many sectors, including automobiles, electronics, and medical equipment, use it often.

One of the main considerations in the insert molding process to guarantee product quality and performance is the dimensional stability of the component.

Functional failure, inadequate assembly, and customer complaints of the product brought on by dimensional instability then impact the reputation and financial gains of the business.

Therefore, controlling the dimensional stability of the product has become an important topic in insert injection molding.

In this article, KRMOLD will discuss with you how to effectively control the dimensional stability of the product in insert molding, including material selection, process parameter optimization, mold design, production environment control, and quality inspection. |  |

1. Influence of Material Selection

1.1 Material properties

Choosing the appropriate plastic material comes first in order to manage dimensional stability. Different plastic materials exhibit varying thermal expansion coefficients, fluidity, and shrinkage, which directly influence the dimensional stability of the finished product.

Designers should avoid using materials with great shrinkage—polycarbonate (PC), polypropylene (PP), etc.—according to the application needs of the product—and select ones with good dimensional stability.

1.2 Use of additives

Adding reinforcement, fillers, or stabilisers can help the substance's dimensional stability to be better.

Glass fiber strengthened polymers, for instance, can drastically enhance the rigidity and strength of products as well as lessen deformation during insert injection molding.

Furthermore enhancing the dimensional stability of goods, heat stabilizers can help to lessen thermal distortion of materials during high-temperature insert injection molding.

2. Optimization of Process Parameters

2.1 Injection temperature control

The fluidity and insert molding quality of polymers are much affected by injection temperature. Too high temperature can cause material decomposition; too low temperature may cause imperfect filling. Appropriate injection temperature adjustment guarantees that the molten plastic fills the mold evenly and prevents dimensional variation brought on by inadequate flow.

2.2 Holding time and pressure

The setting of holding time and pressure directly affects the filling and shrinkage of the product. Properly extending the holding time can help reduce the shrinkage of plastics, thereby improving the dimensional stability of the product.

In addition, reasonable adjustment of the holding pressure can ensure that the molten plastic in the mold maintains a certain pressure during the cooling process, reducing the risk of deformation.

2.3 Cooling time and temperature

The cooling process is also crucial to dimensional stability. Too short cooling time may cause the product to not be fully solidified, thus affecting dimensional stability. By optimizing the cooling system of the mold and ensuring uniform cooling, deformation caused by temperature difference can be effectively reduced.

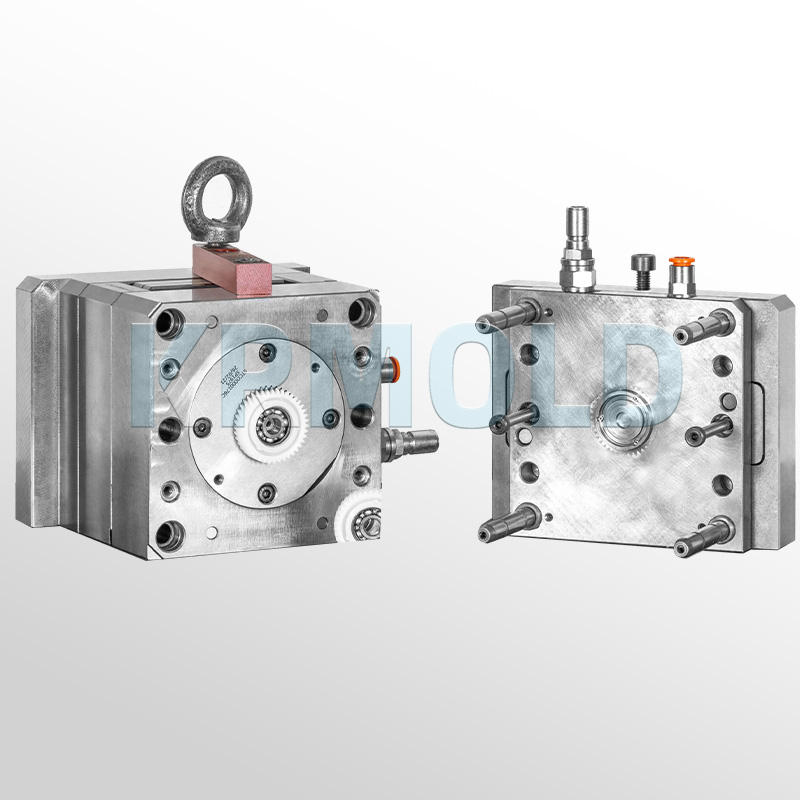

3. Optimization of Mold Design

3.1 Mold material and processing accuracy

The material and processing accuracy of the mold directly affect the dimensional stability of the product.

Selecting mold steel materials with good wear resistance and thermal stability, and ensuring that the processing accuracy of the insert mold is within a reasonable range, can improve the insert molding accuracy of the product.

3.2 Reasonable parting line design

The design of the parting line should try to avoid appearing in the key parts of the product, so as to reduce the dimensional instability caused by the parting line.

In addition, a reasonable parting line design can simplify the manufacture and maintenance of the insert mold and improve production efficiency.

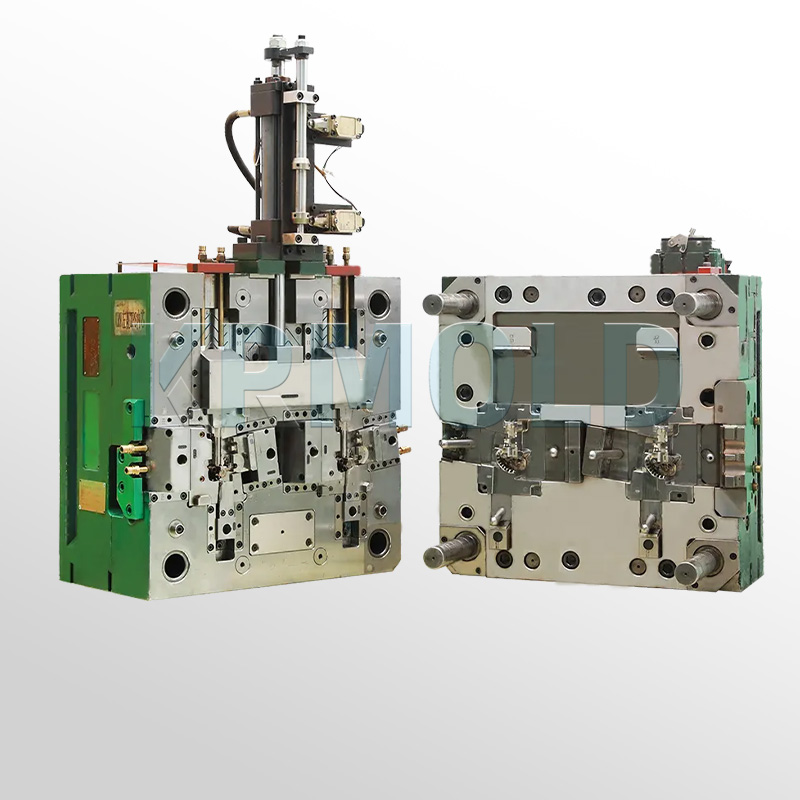

3.3 Design of cooling system

The cooling system of the insert mold should be designed reasonably to ensure that the mold maintains a uniform temperature during the production process.

The layout of the cooling channel should take into account the shape and thickness of the product to ensure the best cooling effect, thereby reducing dimensional changes caused by temperature differences.

4. Control of Production Environment

4.1 Temperature and humidity control

Plastic materials' performance is greatly affected by the humidity and temperature of the manufacturing environment. Changes in the physical qualities of the material, which in turn compromise the dimensional stability of the product, result from too high or too low temperature.

Therefore, proper temperature and humidity should be kept during the insert injection molding process, which is typically advised to be between 20-25℃ambient temperature and 40-60% relative humidity.

4.2 Equipment maintenance and calibration

Regular maintenance and calibration of insert injection molding machines and their supporting equipment are the basis for ensuring production stability. By regularly checking the working status of the equipment and ensuring the accuracy of various parameters, dimensional deviations caused by equipment failure can be avoided.

4.3 Operator training

The stability of insert molding depends directly on the quality and skills of the operators. Operational mistakes may be decreased and the stability of the manufacturing process may be guaranteed by offering operators professional training and enhancing their grasp of process parameters and equipment.

5. Quality Inspection and Control

5.1 Online detection system

The introduction of an online detection system can monitor the dimensional stability of the product in real time. During the production process, by using high-precision measuring equipment, dimensional deviations can be discovered in time and adjusted, thereby reducing the scrap rate.

5.2 Sampling inspection

During the production process, regular sampling inspections are carried out to measure and analyze the dimensions of the products. By statistics and analysis of inspection data, potential quality problems can be found and timely measures can be taken to improve them.

5.3 Feedback mechanism

Establish a perfect quality feedback mechanism to promptly feedback problems in the production process to the design and process team.

By analyzing the feedback information, the design and process parameters can be further optimized to improve the dimensional stability of the product.

6. Case Analysis

Take the insert injection molding production of a home appliance shell as an example. The product has high requirements for dimensional stability. The design team gave priority to polypropylene (PP) material in material selection and added an appropriate amount of glass fiber reinforcement to improve the rigidity and stability of the material. In terms of process parameters, the team determined the optimal injection temperature and holding time through experiments to ensure the quality of the product during the insert molding process.

When designing the insert injection mold, the team used high-precision mold steel materials and carried out a reasonable cooling system design to ensure uniform temperature of the mold during production. During the production process, the team ensured a stable production environment through temperature and humidity control and equipment maintenance.

In terms of quality control, the team introduced an online detection system to monitor product dimensions in real time and conduct sampling inspections. Through data analysis, problems in production were discovered and solved in a timely manner, and the dimensional stability of the product was successfully guaranteed.

7. Future Development Trends of Insert Molding

7.1 Application of intelligent manufacturing technology

With the development of intelligent manufacturing technology, dimensional stability control in insert injection molding will be more accurate. Through big data analysis and artificial intelligence technology, real-time monitoring and optimization of the production process can be achieved, and the level of automation of production can be improved.

7.2 Research and development of new materials

The research and development of new plastic materials will provide more options for dimensional stability control. In the future, with the advancement of new material technology, designers will be able to choose more stable and functional materials to meet increasingly complex product needs.

7.3 Introduction of green production concept

With the promotion of the concept of sustainable development, dimensional stability control in insert molding will also focus on environmental protection and sustainability.

In the future, the production process will pay more attention to the recyclability of materials and the energy efficiency of the production process to reduce the impact on the environment.

Controlling the dimensional stability of products in insert injection molding is a key factor in ensuring product quality. Through reasonable material selection, process parameter optimization, mold design, production environment control and quality inspection, the dimensional stability of products can be effectively improved.

In the future, with the advancement of technology and changes in market demand, dimensional stability control in insert molding will usher in new opportunities and challenges, injecting new vitality into the development of the industry.