KINGREAL UNIVERSAL IND., LTD

Phone

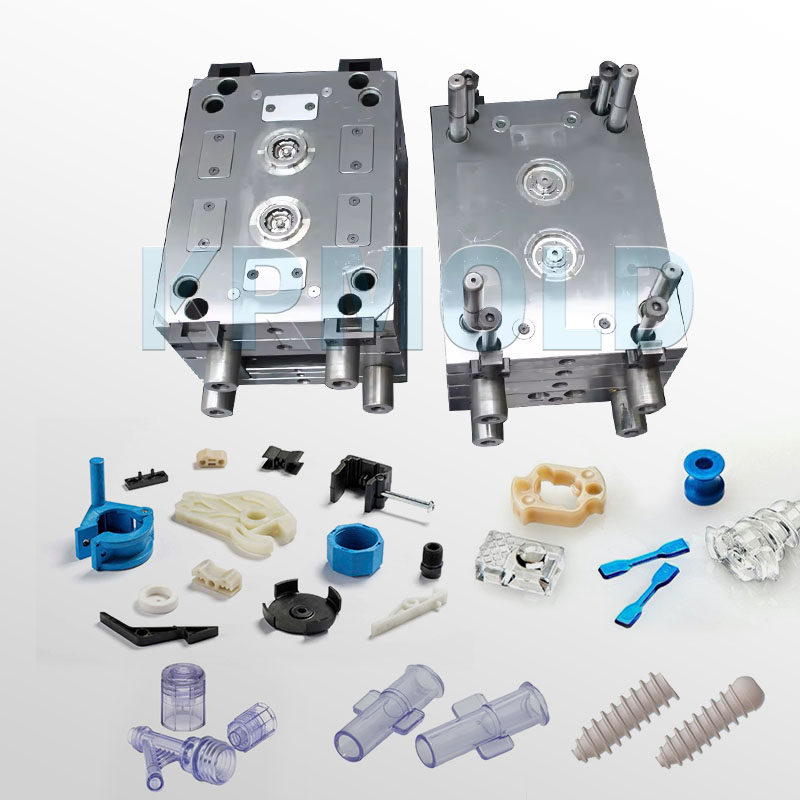

+86-13702855825Micro injection molding is a commonly used plastic injection molding technology in modern manufacturing, which is widely used in many fields. In the micro injection molding process, the dimensional stability of the product is one of the key factors to ensure product quality and performance. Dimensional instability may lead to functional failure, poor assembly and customer complaints of the product, which in turn affects the reputation and economic benefits of the company. Therefore, how to control the dimensional stability of the product has become an important topic in micro injection molding. In this article, KRMOLD will discuss with you how to effectively control the dimensional stability of the product in micro injection molding. If you want to get more information about micro injection molds, please come to consult KRMOLD!

| 1 | Influence of Material Selection |

| 2 | Process Parameter Optimization |

| 3 | Optimization of Mold Design |

| 4 | Control of Production Environment |

| 5 | Quality Inspection and Control |

1. Influence of Material Selection

(1) Material Characteristics The first stage in dimensional stability control is selecting the right plastic. Various plastic materials have varying thermal expansion coefficients, fluidity, and shrinkage that directly affect the dimensional stability of the final product. Based on the product's application requirements, designers should pick materials with acceptable dimensional stability, such polycarbonate (PC), polypropylene (PP), etc.; stay away from those with high shrinkage.

(2) Use of additions Adding stabilizers, fillers or reinforcing agents helps to increase the dimensional stability of the material. Glass fiber reinforced polymers, for instance, can greatly increase material stiffness and strength as well as minimize deformation during the micro injection molding process. Furthermore enhancing the dimensional stability of products, the use of heat stabilizers can lessen the thermal deformation of materials undergoing high-temperature molding. |  |

2. Process Parameter Optimization

(1) Regulation of injection temperature The fluidity and molding quality of polymers depends much on injection temperature. Too high injection temperature could lead to material degradation; too low temperature may result in insufficient filling. Appropriate injection temperature adjustment guarantees that the molten plastic smoothly fills the micro injection molds and prevents dimensional inaccuracy brought on by bad flow.

(2) Pressuring time and holding The setting of maintaining pressure and time directly impacts the product's shrinkage and filling. Correctly extending the holding time helps to lower plastic shrinkage and so improve the dimensional stability of the item. Moreover, appropriate adjustment of the holding pressure can help the molten plastic in the micro injection molds keep a specific pressure during the cooling process and lessen the danger of distortion.

(3) Cooling temperature and time Dimensional stability also depends on the cooling mechanism. Too short cooling time might prevent the object from completely solidifying, therefore compromising dimensional stability. Effective reduction of deformation brought on by temperature difference can be achieved by means of micro injection molds cooling system optimization and uniform cooling guarantee. |  |

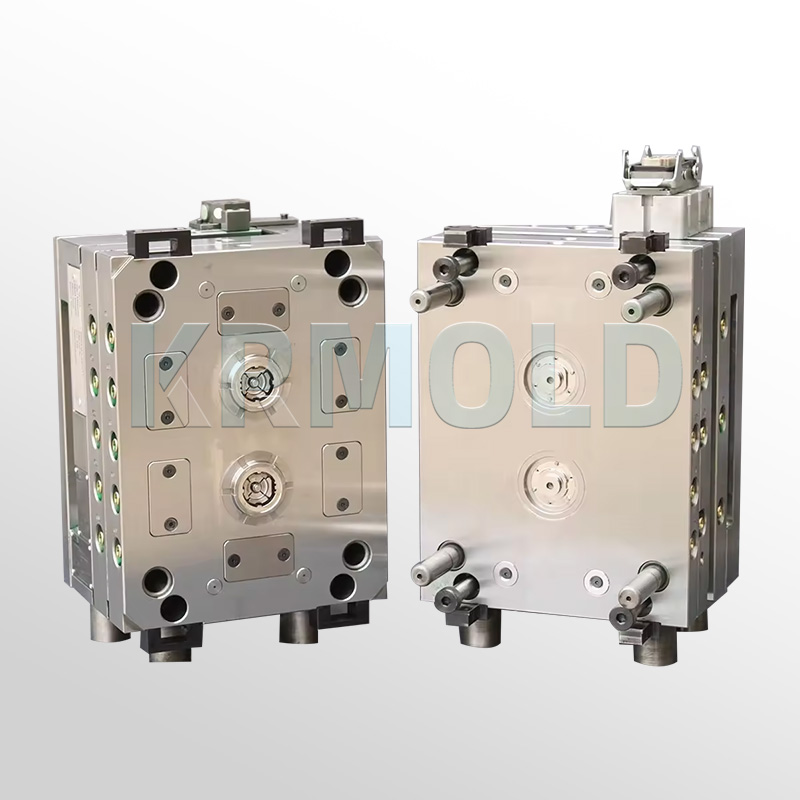

3. Optimization of Mold Design

(1) Mold material and processing accuracy The material and processing accuracy of the micro injection molds directly affect the dimensional stability of the product. Selecting micro injection molds steel materials with good wear resistance and thermal stability, and ensuring that the processing accuracy of the micro injection molds is within a reasonable range, can improve the molding accuracy of the product.

(2) Reasonable parting line design The design of the parting line should try to avoid appearing in the key parts of the product, so as to reduce the dimensional instability caused by the parting line. In addition, a reasonable parting line design can simplify the manufacture and maintenance of the micro injection molds and improve production efficiency.

(3) Design of cooling system The cooling system of the micro injection molds should be reasonably designed to ensure that the mold maintains a uniform temperature during the production process. The layout of the cooling channel should take into account the shape and thickness of the product to ensure the best cooling effect, thereby reducing dimensional changes caused by temperature differences. |  |

4. Control of Production Environment

(1) Control of temperature and humidity Plastic material performance is much influenced by production environment temperature and humidity. Changes in the physical qualities of the material brought on by too great or too low temperature will impact the dimensional stability of the product. Therefore, throughout the micro injection molding manufacturing process, proper temperature and humidity should be kept and it is often advised to maintain an ambient temperature of 20-25°C and a relative humidity of 40-60%.

(2) Equipment adjustment and maintenance Stability in production depends on regular maintenance and calibration of micro injection molding equipment and their supporting systems. Regular inspection of the working condition of the equipment and confirmation of the accuracy of several variables help to prevent dimensional variations produced by equipment failure.

(3) Operator instruction The stability of micro injection molds depends directly on the skill and quality of operators. Professional development for operators and better understanding of process criteria and equipment will help to lower operational mistakes and guarantee process stability. |  |

5. Quality Inspection and Control

(1) Online detection system The introduction of an online detection system can monitor the dimensional stability of the product in real time. During the production process, by using high-precision measuring equipment, dimensional deviations can be discovered in time and adjusted, thereby reducing the scrap rate.

(2) Sampling inspection During the production process, regular sampling inspections are carried out to measure and analyze the dimensions of the products. By analyzing the inspection data, potential quality problems can be found and timely measures can be taken to improve them.

(3) Feedback mechanism Establish a complete quality feedback mechanism to promptly feedback problems in the production process to the design and process team. By analyzing the feedback information, the design and process parameters can be further optimized to improve the dimensional stability of the product. |  |