KINGREAL UNIVERSAL IND., LTD

Phone

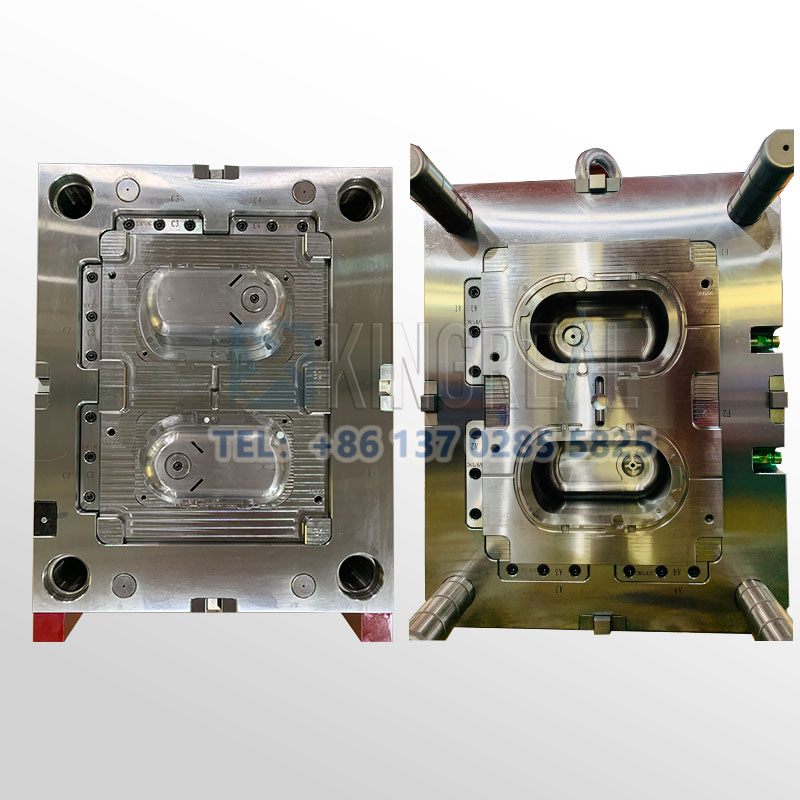

+86-13702855825Multi cavity injection molding yields several components in a single injection cycle. Multi cavity injection molds can simultaneously create several components because they have several cavities. Multi cavity injection molds are therefore quite useful for mass production sectors including consumer goods, packaging, and automobile components. Multi cavity injection molding has to make sure every cavity has a steady flow of heated polymer. This helps you to create several cavities and better manage the molding parameters. For manufacturing plastic components for products with steady and great volume needs, such as bottle caps or small electronic cases, this kind of mold is ideal. This article will show you how three ways that multi cavity injection molding can greatly boost production efficiency: the difference between single cavity injection molds and multi cavity injection molds, the benefits of multi cavity injection molding, and the major design factors for multi cavity molds. Please come to consult KRMOLD if you are interested in multi cavity injection molds and would like to learn more about multi cavity injection molding. |  |

| 1 | Single Cavity Injection Molds vs Multi Cavity Injection Molds |

| 2 | Advantages of Multi Cavity Injection Molding |

| 3 | Principal Design Factors for Multi Cavity Injection Molds |

1.Single Cavity Injection Molds vs Multi Cavity Injection Molds

There are many plastic injection molding methods; hence, there is no right or bad dictum. Based on the genuine circumstances, you just need to select the ideal plastic injection mold.

Single cavity injection molding: It only has one cavity, hence each single cavity injection molding process may only yield one item. Prototypes, small-batch manufacture, or complicated parts needing exacting details can all be produced using single-cavity molds. |  |

Multi cavity injection molding: It generates many components in one injection cycle. Multi cavity injection molds have several cavities and can make many pieces concurrently. Hence, mass manufacturing sectors like consumer goods, packaging, and automotive components benefit greatly from multi cavity injection molds.Multi cavity injection molding has to guarantee that every cavity has a consistent flow of hot plastic. Better molding conditions control helps you create several cavities. For creating plastic components for goods with consistent and great volume needs—such as bottle caps or small electronic housings—this kind of mold is ideal. |  |

Single cavity injection molds | ||

Production volume | Low to medium volume | High volume |

Tooling cost | Lower initial cost | Higher initial cost |

Cost per part | Higher for small production runs | Lower for larger production runs |

Design adjustments | Easy to implement | Complex, affecting multiple cavities |

Cycle times | Longer, one part per cycle | Shorter, multiple parts per cycle |

Complex part handling | Suitable for complex and detailed designs | Best for simple, repetitive designs |

Scalability | Not suitable for large-scale operations | Highly scalable for high-demand production |

2.Advantages of Multi Cavity Injection Molding

①Higher production efficiency

The multi cavity injection molding process can mold multiple parts at a time, thereby reducing the time for large-scale production. For example, instead of producing only one bottle cap per production cycle, a mold with eight cavities is used, which means that more than eight bottle caps can be produced at a time.

②Reduced unit cost

Although the tooling cost of multi cavity injection molds is relatively high, the cost of a single part will decrease as the number of parts produced increases.

Since it is a cost-effective product, it is suitable for large-scale production.

③Faster orders

Since multi cavity injection molds can produce multiple parts at once, they are very useful when you have large orders. Faster orders are more advantageous for industries such as consumer goods, where fast reaction times are critical for plastic products.

④Stable quality

Well-designed multi-cavity injection molds require that all cavities receive the same amount of molten plastic in order to produce identical parts. For example, if you produce food trays, they need to be of the same size and quality to meet industry standards.

⑤Optimize resource utilization

Multi cavity injection molds ensure that each function of each multi cavity injection molding process is optimized at the maximum capacity of the machine.

This reduces the waste of time and energy, allowing manufacturers to produce more products without investing in new machines.

3.Principal Design Factors for Multi Cavity Injection Molds

| Apart from standard factors for mold growth, manufacturers using multi cavity injection molds should give particular attention to: Achieving good cavity balance is absolutely necessary to guarantee consistent filling, cooling, and ejection during the procedure. To guarantee the consistency of the design, this entails altering the gate size, runner system, and cooling channels to reduce abrupt turns and curves in the layout. Design an effective runner system allowing the correct material flow to each cavity in multi cavity injection molds. To guarantee balanced and regulated material distribution, consider aspects like gate design, runner sizing, and runner arrangement. Effective cooling guarantees that all cavities are uniformly cooled, hence another crucial element is setting up a cooling system. Good cooling lowers cycle times, prevents part warping, and raises output. Think about cooling channel placement and the use of baffles or cooling inserts to maximize cooling effectiveness. Finally, material selection and construction help to guarantee the mold operates as planned. Select the appropriate mold material and construction methods to guarantee endurance and longevity. Consider variables like mold steel choice, surface coverings, and mold maintenance demands to guarantee the mold can handle the demands of large-volume production. |