KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| PPE injection molding is an important and common molding method in modern plastic processing technology. PPE plastic injection molding is widely used in many industries due to its excellent physical and chemical properties. Before we delve into PPE injection molding process and application areas, let's first understand the basic characteristics of PPE. |  |

| 1 | Basic Characteristics of PPE |

| 2 | Introduction to PPE Injection Molding Process |

| 3 | Application of PPE Injection Molding |

1.Basic Characteristics of PPE

PPE materials are mainly divided into three types: heat-resistant grade, flame retardant and enhanced flame retardant grade. They each have the following advantages:

High rigidity: PPE has a large rigidity, which makes it difficult to deform under high load.

High heat resistance: Its thermal decomposition temperature can reach 350℃, and there is almost no obvious thermal degradation phenomenon below 300℃.

Flame retardancy: PPE material has good flame retardant properties and is suitable for occasions with strict requirements for fire protection.

Excellent electrical properties: This makes PPE widely used in the electronic and electrical industry.

Wear resistance: The wear resistance of PPE makes it suitable for mechanical parts.

Non-toxic and pollution-resistant: PPE materials do not release harmful substances and are suitable for food and medical fields.

These characteristics make PPE the material of choice in many fields.

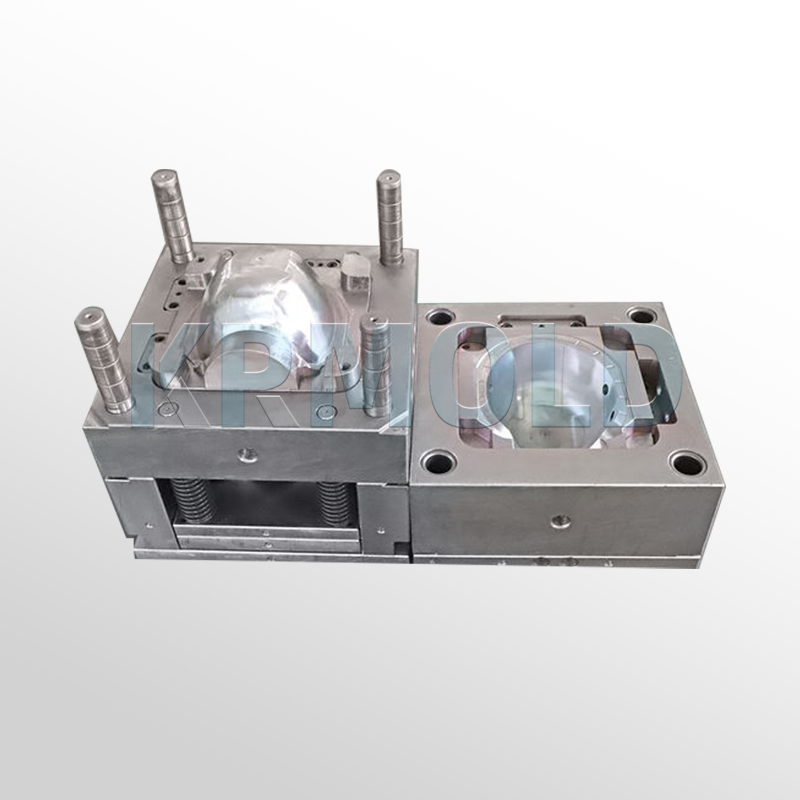

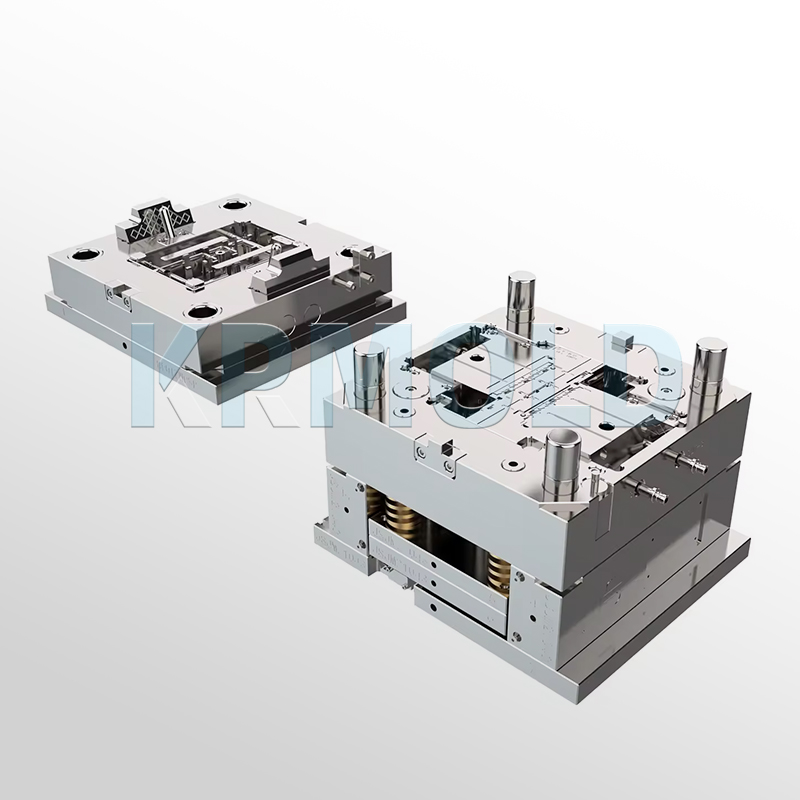

2.Introduction to PPE Injection Molding Process

| The process of PPE plastic injection molding involves precise control of multiple parameters to ensure the quality of the final product. The following are some key molding process parameters:

(1) Temperature control for PPE plastic injection molding Barrel temperature: usually controlled at 260~290℃, and the nozzle temperature should be about 10℃ lower than the barrel temperature to avoid overheating and degradation. Mold temperature: Due to the high viscosity of PPO melt, a higher mold temperature is required during injection molding, usually controlled at 100~150℃. Mold temperature below 100℃ may cause insufficient mold filling and delamination, while above 150℃ may cause defects such as bubbles, silver wire and warping. (2) Injection pressure for PPE plastic injection molding Injection pressure: Appropriately increasing the injection pressure is conducive to the filling of the melt, usually controlled at 100-140MPa. Holding pressure: Generally maintained in the range of 40%-60% of the injection pressure to ensure stable pressure in the mold. (3) Back pressure and injection speed Back pressure: set at 3-10MPa (30-100bar) to ensure uniform melt. Injection speed: For products with long runners, fast injection is required to ensure smooth flow of the melt in the mold. (4) Screw speed and metering stroke Screw speed: should maintain a medium speed, equivalent to a linear speed of 0.6m/s. Metering stroke: ranges from 0.5-3.5D, depending on the requirements of the mold and product. (5) Pre-drying and recycling Pre-drying: dry at 110℃ for 2 hours to remove moisture from the material and avoid bubbles during molding. Recycling rate: PPE material has good regeneration processing capabilities and can be reused as long as the recycled material has not been thermally degraded. (6) Shrinkage rate and gate system Shrinkage rate: The shrinkage rate of PPE is usually between 0.8%-1.5%, which needs to be adjusted appropriately according to the specific product. Gate system: Small products can use point or latent gates, while larger products should use straight gates or disc gates. For hot runner systems, the heating system can be turned off when the machine is shut down to keep the temperature stable. (7) Barrel equipment Equipment configuration: Standard screws, check rings and straight-through nozzles are required to ensure smooth conveying and molding of the molten material. |

3.Application of PPE Injection Molding

| The wide application of PPE plastic injection molding is mainly concentrated in the following industries: |

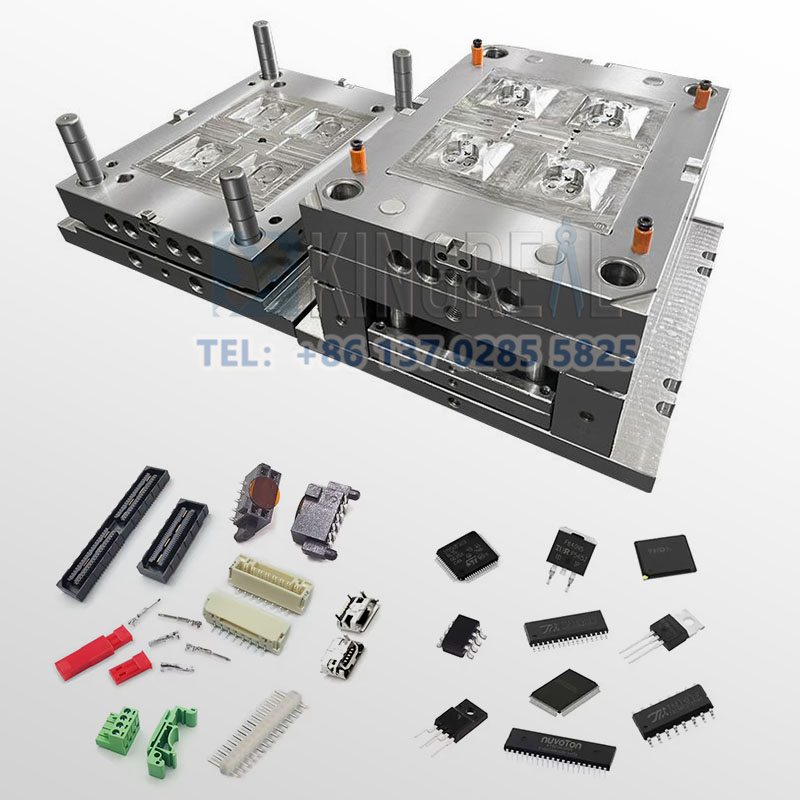

(1) PPE plastic injection molding in electronic and electrical industry In the electronic and electrical field, PPE materials can maintain excellent electrical insulation in humid, high-load and high-temperature environments. Common applications include: TV tuners Coil cores Microwave insulation parts Shielding sleeves High-frequency printed circuit boards Various high-voltage electronic components Casings of TVs, computers, fax machines, and copiers These applications fully demonstrate the importance of PPE in high-tech products. |

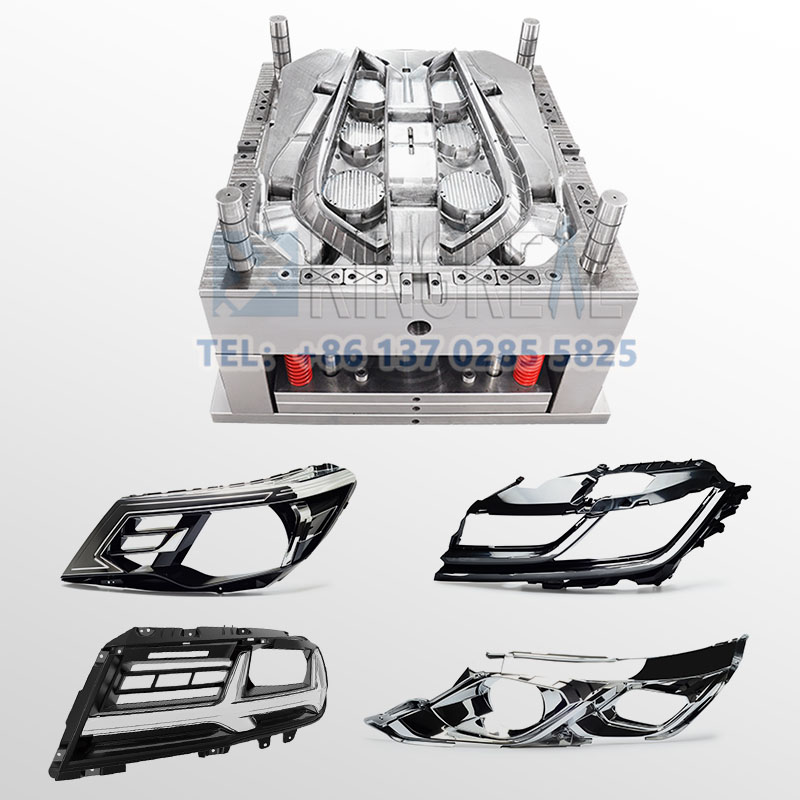

(2) PPE injection molding in automotive industry In the automotive industry, PPE is widely used in: Instrument panels Window frames Shock absorbers Pump filters and other parts Due to its excellent heat resistance and strength, PPE materials can effectively improve the durability and safety of automotive parts. |

| (3) PPE injection molding in mechanical industry The application of PPE materials in the mechanical industry includes: Gears Bearings Pump impellers Blower impellers These parts need to withstand large mechanical loads, and the rigidity and wear resistance of PPE make it an ideal material. |

(4) PPE injection molding in chemical industry In the chemical industry, PPE is often used to make corrosion-resistant pipes, valves, filters, submersible pumps and other parts. These applications require materials with good chemical resistance and mechanical strength, and PPE just meets these requirements. |

|