KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Smart home injection molds: shaping the beauty of smart home form |

| 2 | Smart home injection molds: driving functional innovation in smart homes |

| 3 | The Foundation and Current Status of Integration |

| 4 | Integrated Innovation Models |

| 5 | Smart Home Injection Molds Create New Market Opportunities |

Smart home integration injection molds are essential tools for producing a variety of high-precision smart home products. This article will explain how these smart home injection molds benefit manufacturers.

1. Smart home injection molds: shaping the beauty of smart home form

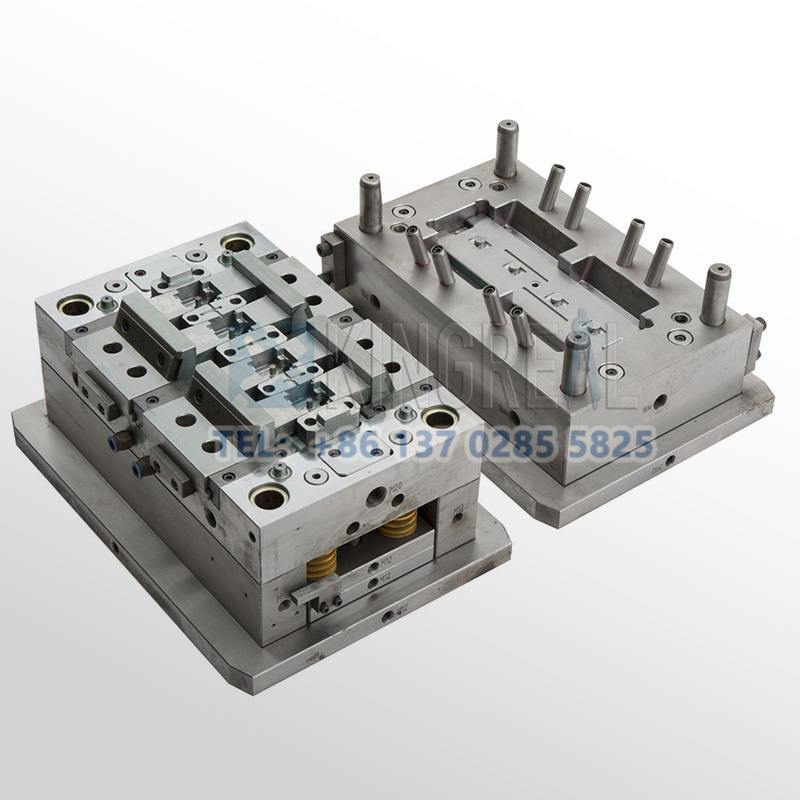

Smart home integration injection molds are key tools in plastic injection molding. In the smart home industry, whether it's the streamlined housing of a smart speaker, the sturdy panel of a smart door lock, or even the tiny base of a smart light-bulb, smart home injection molds are essential. With rigorous process flow and precise design, smart home integration injection molds ensure the aesthetic appeal and structural stability of smart home products.

Smart home injection molds offer endless possibilities for the design of smart home products. They can showcase simple, modern lines or elegant, retro curves, providing a wide range of design options for integrating smart homes into everyday homes. This diverse design not only enhances product competitiveness but also increases consumer purchasing desire.

2. Smart home injection molds: driving functional innovation in smart homes

Smart home integration injection molds not only shape the external form of smart homes but also drive deeper functional innovation. With the advancement of materials science, smart home injection molds are now capable of processing a variety of high-performance plastics and composite materials. These new materials often possess excellent insulation, heat resistance, and corrosion resistance, providing the material foundation for the miniaturization, light-weighting, and multi-functionality of smart home devices.

For example, high-strength, high-toughness plastic components produced using smart home integration injection molds enable smart sweeping robots to maneuver flexibly in complex environments without fear of collisions. In another example, conductive plastics processed using smart home injection molds enable smart switches to implement touch sensing and remote control, greatly enhancing the user experience. Smart home integration injection molds' ability to harness new materials is helping smart homes continuously push the boundaries of functionality, transitioning from single functions to integrated, intelligent systems.

3. The Foundation and Current Status of Integration

(1) Technical support for smart home injection mold industry

The high precision and efficiency of smart home integration injection molds make them a key tool in plastic injection molding. In the smart home industry, the housings and components of numerous products rely on smart home injection molds.

For example, the housing of a smart speaker must not only be aesthetically pleasing but also ensure acoustic performance, requiring smart home integration injection molds to precisely control parameters such as wall thickness and surface roughness.

The smart home injection mold industry's evolving precision manufacturing technologies, such as high-speed milling and electro-discharge machining (EDM), are meeting the high-precision component demands of smart home products.

Furthermore, the increasing automation in smart home integration injection mold manufacturing, leveraging computer-aided design (CAD) and computer-aided manufacturing (CAM), has enabled efficient and precise production processes, providing a solid foundation for large-scale production in the smart home industry.

(2) Demand for smart home injection molds in smart home industry

The rapid expansion of the smart home industry has driven massive demand for a wide range of products. Consumers are increasingly demanding the design and functional integration of smart home products, prompting manufacturers to continuously launch innovative and personalized products. The realization of these products relies on innovative smart home integration injection mold design and manufacturing.

Take smart cameras, for example. To meet the requirements of different installation scenarios, their designs may take on a variety of shapes, such as spherical or cylindrical, and must also incorporate features such as waterproofing and dust-proofing. The smart home injection mold industry needs to develop customized smart home integration injection molds based on these diverse design requirements to ensure product quality and performance.

4. Integrated Innovation Models

(1) Collaborative Design Innovation

Traditional mold design is often conducted after receiving product design drawings, resulting in a lag in communication between mold and product designers. In the integrated innovation of the smart home and injection mold industries, collaborative design has become a key model. Smart home product designers and injection mold designers collaborate closely from the product concept design stage. Through a shared design platform, they exchange ideas in real time and jointly optimize product designs.

This collaborative design approach can avoid smart home integration injection mold development difficulties and product quality issues caused by poor design, while also shortening the product design-to-market cycle. By intervening early in product design, smart home injection mold companies can better leverage their expertise and provide more innovative and feasible design solutions for smart home products.

(2) Material Innovation and Application

Smart home products have unique material performance requirements, requiring them to meet functional requirements while also balancing environmental and aesthetic considerations. The smart home integration injection mold industry is actively participating in material innovation and application, collaborating with material suppliers to develop new plastic materials suitable for smart homes.

For example, developing highly flame-retardant plastics for smart appliance housings improves product safety; developing antibacterial plastics for smart kitchen appliances protects user health. At the same time, smart home injection mold companies are improving the injection molding process to effectively mold new materials, ensuring uniform filling of the material in the smart home injection mold and producing high-quality products.

(3) Intelligent Manufacturing Integration

With the advancement of Industry 4.0, intelligent manufacturing has become a key direction for the integration of the smart home injection mold industry and the smart home industry. The introduction of automated equipment, robots, and intelligent control systems in the mold manufacturing process enables intelligent smart home injection mold production.

For example, automated machining centers are used for high-precision machining of mold components, robots are used for mold handling and assembly, and intelligent monitoring systems are used to monitor various parameters during the smart home injection mold production process in real time. This intelligent smart home integration injection molding solution can improve production efficiency, reduce production costs, and provide strong support for the large-scale, high-quality production of smart home products.

5. Smart Home Injection Molds Create New Market Opportunities

Integrated innovation models are creating new market opportunities. As the performance and quality of smart home products improve, market demand is further expanding, creating more business opportunities for smart home integration injection mold companies.

In addition to traditional product housing and component manufacturing, smart home injection mold companies can also expand into areas such as structural and functional components for smart home products.

Furthermore, the new technologies and processes generated through convergent innovation offer new market entry points for related companies. These companies can transform these technologies into products or services, promote them to other companies in the industry, and open up new market opportunities.