KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Silicone rubber injection molding is a common method in plastic injection molding. Many people are curious about the workflow, advantages and application areas of silicone rubber injection molds. In this article, KRMOLD will answer them one by one. If you are interested in silicone rubber injection molding, or need to obtain more information about silicone rubber injection molds, please come to consult KRMOLD!

| 1 | Process of Silicone Rubber Injection Molding |

| 2 | Advantages of Silicone Rubber Injection Molding |

| 3 | Applications of Silicone Rubber Injection Molding |

1.Process of Silicone Rubber Injection Molding

Silicone rubber is a two-component liquid material, divided into component A and component B. The mixer works to fully mix component A and component B in a precise 1:1 ratio. Because some products are colored, they are equipped with a color pump group and a color metering part. After fully mixing, components A+B, additives, colors, etc. enter the plasticizing system. This plasticizing screw has the functions of homogenization and mixing. The mixed material is injected into the hot mold through the screw. At a mold temperature of 170-200℃, the silicone undergoes a curing reaction. When using a cold runner system, it is worth noting that the runner must be cold enough. In order to avoid glue leakage, the needle valve is installed on the surface of the silicone rubber injection molds component. When the injection is completed, the needle valve immediately closes the nozzle.

(1.1) Feeding system The following forms can be selected: (1.1.1) Bidirectional pump It can move up and down to feed the material and can maintain the pressure well. Since the A and B pumps are connected and synchronously controlled by hydraulic pneumatic, this type of feeding system is more reliable and accurate. (1.1.2) Unidirectional pump It is a general type and can only feed one way. (1.1.3) Synchronous unidirectional pump with check valve (1.1.4) Measuring cylinder system It is mainly used in conjunction with unidirectional pumps. |  |

(1.2) Key components of silicone rubber injection molding machine (1.2.1) Due to the low viscosity of silicone rubber, the back flow and leakage of materials must be considered during the processing, so the sealing of the screw is necessary. (1.2.2) In order to prevent silicone rubber from solidifying, a needle valve nozzle should be used. (1.2.3) Mixing and metering components of components A and B. |  |

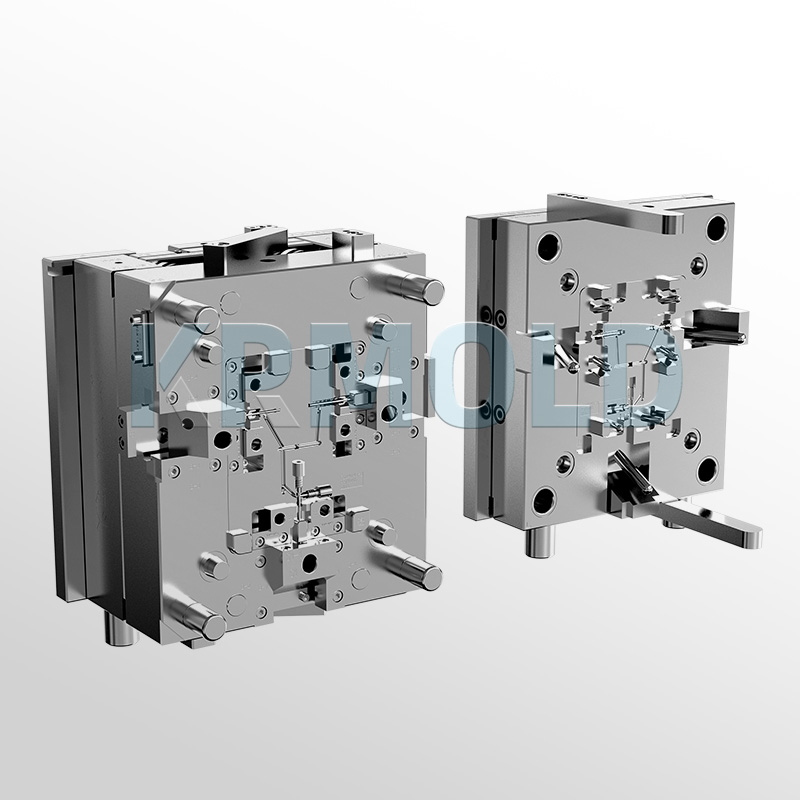

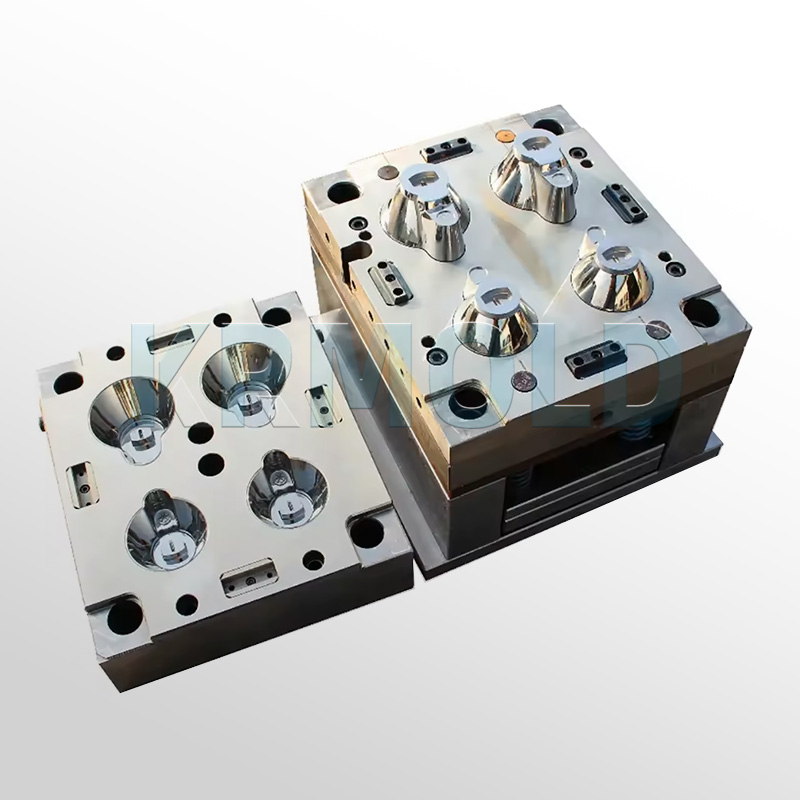

(1.3) Silicone rubber injection molds design In silicone rubber injection molds design, there are generally the following forms: (1.3.1) Hot runner It is more wasteful of materials, simple in design, low in cost, and is mostly used for large products. (1.3.2) Cold runner with needle valve Automation is possible with short cycle time. (1.3.3) Cold runner without needle valve Due to the high expansion coefficient of silicone rubber, it expands when heated and shrinks slightly when cooled, so the parts cannot maintain precise side margins in the mold. Therefore, cold runner processing can be used. silicone rubber should maintain a low temperature and fluidity. The cold runner adopts a closed system. During the injection cycle, the closed system uses a "sealing needle" or "needle valve" in each runner to control the accurate metering of silicone rubber. Due to the significant thermal expansion characteristics of silicone rubber, the shrinkage rate is 2% to 4% (vulcanization temperature is 150°C), and silicone rubber has the characteristics of compression deformation. |  |

2.Advantages of Silicone Rubber Injection Molding

(1) High precision and good consistency One of the most significant advantages is silicone rubber injection molding’s ability to produce silicone parts with high precision and consistency. The process is extremely precise, allowing manufacturers to produce complex shapes and intricate details with tight tolerances. These accuracies are critical to industries such as healthcare and aerospace, where even the slightest deviation can have serious consequences.

(2) Compatibility with Complex Designs Finally, silicone rubber injection molding is compatible with complex designs and can manufacture parts with complex geometries that are difficult or impossible to achieve with other manufacturing methods. This compatibility opens up a variety of design possibilities, enabling the production of highly specialized and customized silicone parts.

(3) Efficiency and Speed Advanced silicone rubber injection molding machines offer fast cycle times, allowing for high-volume production in a relatively short period of time. This efficiency is beneficial for meeting high-volume demands, reducing overall production time, and the overall cost of silicone rubber injection molding parts.

(4) Flexibility in Materials and Colors Silicone rubber injection molding offers flexibility in material and color selection. A wide range of silicone with different properties can be customized to the specific requirements of the final product. In addition, different colors can be achieved by adding pigments and additives.

(5) Enhanced Strength and Durability The process ensures that material properties, such as tear resistance and tensile strength, are evenly distributed throughout the part. As a result, molded silicone parts become strong and durable, able to withstand a variety of environmental stresses.

(6) Minimal Waste Generation Silicone rubber injection molding is very efficient in terms of material usage. Therefore, it generates minimal waste. Excess materials can often be recycled and reused, contributing to sustainable manufacturing practices. This efficiency reduces material costs and waste disposal costs. |  |

3.Applications of Silicone Rubber Injection Molding

Due to its excellent performance in many aspects, silicone rubber injection molds is used in many fields.

(1) Baby and children's products. Because silicone is soft to the touch, friendly to the human body and non-allergenic, it is widely used in children's toys, baby pacifiers, etc.

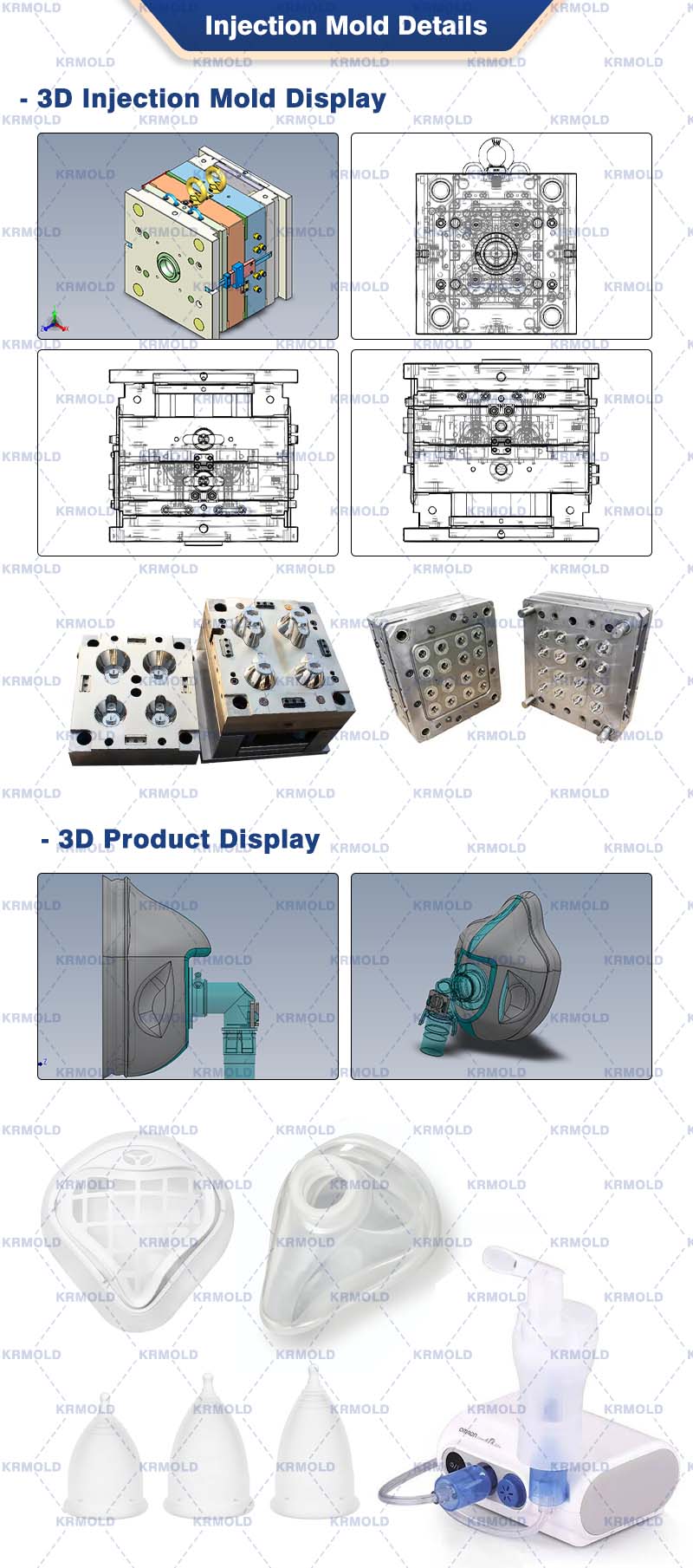

(2) Medical products. Due to its inertness, flexibility, heat resistance and sterilization performance, it is widely promoted in medical products, medical implants, inhalers, and seals. Since the profit margin of medical products is relatively high, the application of silicone rubber has a very broad prospect

(3) Electronic products and automotive industry. Thanks to silicone's high temperature resistance: unique chemical structure, excellent electrical insulation properties, and compression resistance, silicone rubber injection molds are widely used in keyboards, connector seals, and shock absorbers. Currently, silicone rubber injection molding used in the automotive industry accounts for about 1/3 of the total usage, which is the largest field, such as headlight lenses, automotive plug connectors, etc.

(4) Optical industry. Silicone has excellent transparency, uniform internal structure without stress, UV resistance and other properties, and is gaining more and more attention in lenses, light guides, solar panels, etc.