KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825IMD Injection Molding, also known as In-Mold Decoration, is a decorative technology that combines printed film with plastic resin in an injection mold. This In-Mold Decoration technology can form a decorative pattern with a printed texture on the surface of plastic products, while providing a wear-resistant and scratch-resistant protective layer. IMD Injection Molding is widely used in automotive interiors, electronic products, home appliances, medical equipment and other fields to make decorative panels with complex patterns and colors. Compared with traditional spraying or labeling processes, In-Mold Decoration can achieve higher decorative effects and durability while reducing production steps and material waste. |  |

| 1 | Process of IMD Injection Molding |

| 2 | Application of IMD Injection Molding |

Process of IMD Injection Molding

1. Cutting.

The first phase in the In-Mold Decoration process is cutting. Generally, a high-precision cutting machine is used to cut the roll or sheet film material into sheets of particular sizes for next printing and molding. To prevent material waste and lower production efficiency, it is imperative during the cutting process to guarantee the integrity of the material and the precision of the size.

2.Flat printing, two times.

One critical stage in the IMD Injection Molding process—which involves transferring the intended design, text, etc. onto cut film via screen printing or other printing method—flat printing is To guarantee the appearance quality of the ultimate item, this stage calls for very great accuracy and color consistency.

3.Ink drying and repair.

The design must undergo a drying and fixing procedure following printing to guarantee its firmness and long use. Usually performed in a high-temperature oven, the drying procedure calls for strict control of time and temperature to guarantee the ultimate ink performance.

4. Applying protective film.

Usually applied to the surface of the printed film are one or more layers of protective film to shield it from scratching or damage in later processes. The finished quality and manufacturing effectiveness of the goods are greatly influenced by the choice of protective film as well as the way it is applied.

5. Punching alignment holes help to guarantee correct mold placement of the film in the next thermoforming and In-Mold Decoration phases.

This phase calls for exact mold design and stamping techniques to guarantee product accuracy and consistency.

6.A crucial stage in the IMD Injection Molding process, thermoforming turns a flat film into a three-dimensional form by means of heating and high-pressure IMD Injection Molding.

Therefore giving the final product its three-dimensional character. This stage demands extremely high standards for process parameter control, molding equipment, and material selection.

7. Cutting the peripheral shape

After thermoforming, the film needs to cut off the excess peripheral part to obtain an accurate appearance that matches the shape of the final product. This step usually requires precision cutting molds and equipment to ensure smooth and neat cutting edges.

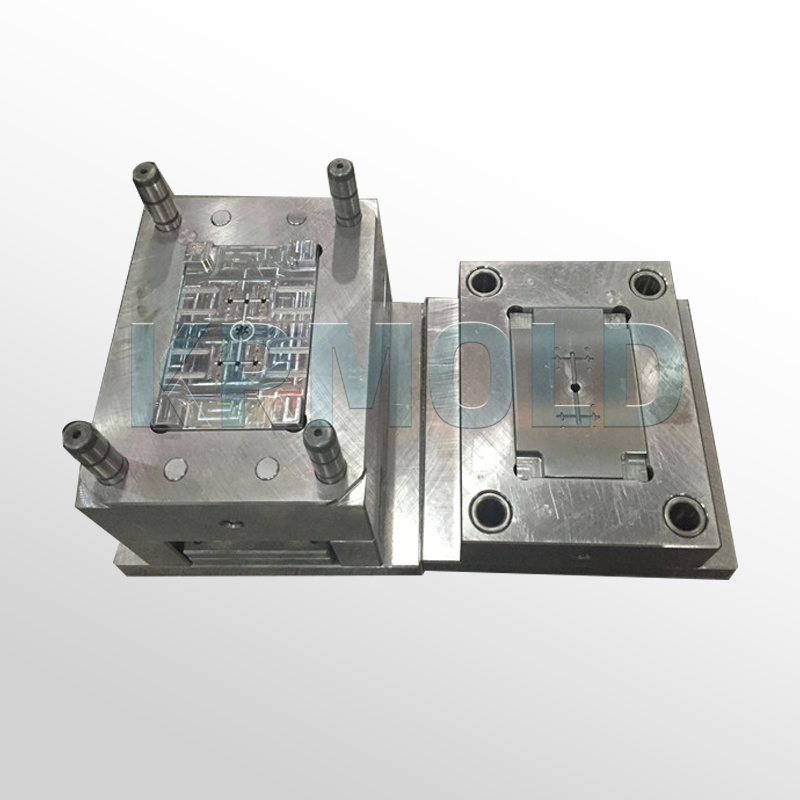

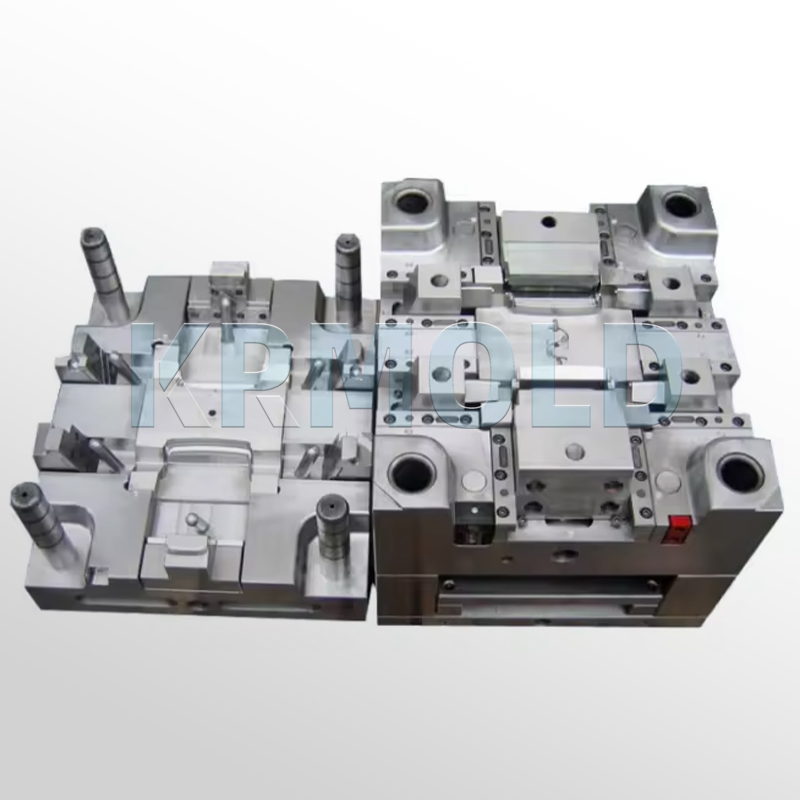

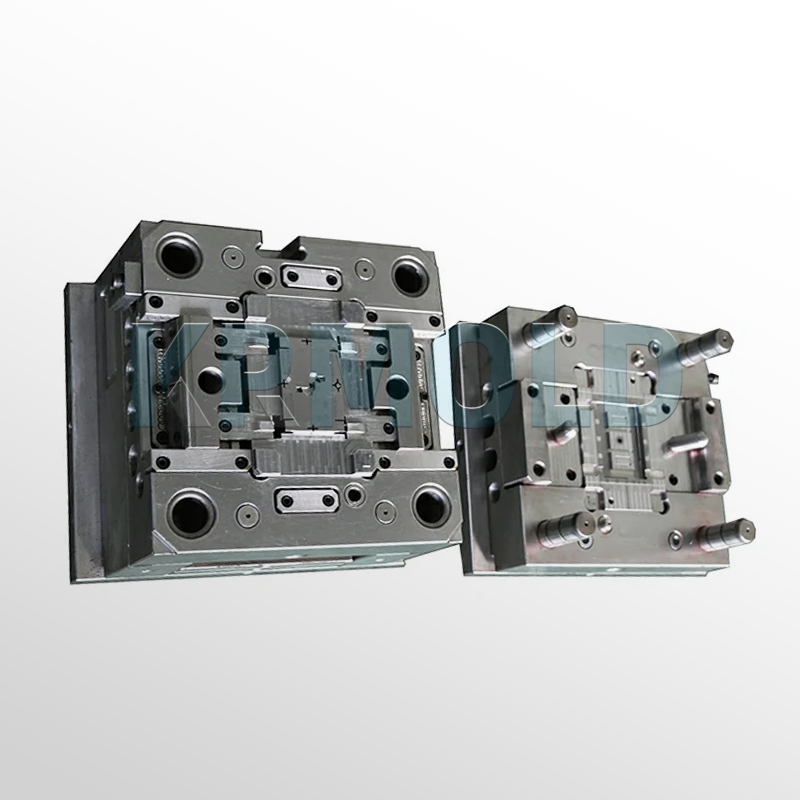

8. In-Mold Decoration

The last step of the IMD Injection Molding process is injection molding, which puts the formed film into the injection mold and injects molten plastic material to combine the film with the plastic substrate to form a final product with a printed pattern. During the In-Mold Decoration process, the selection of plastic materials, injection temperature, pressure, cooling time and other parameters have a direct impact on the appearance quality, physical properties and production efficiency of the product.

Application of IMD Injection Molding

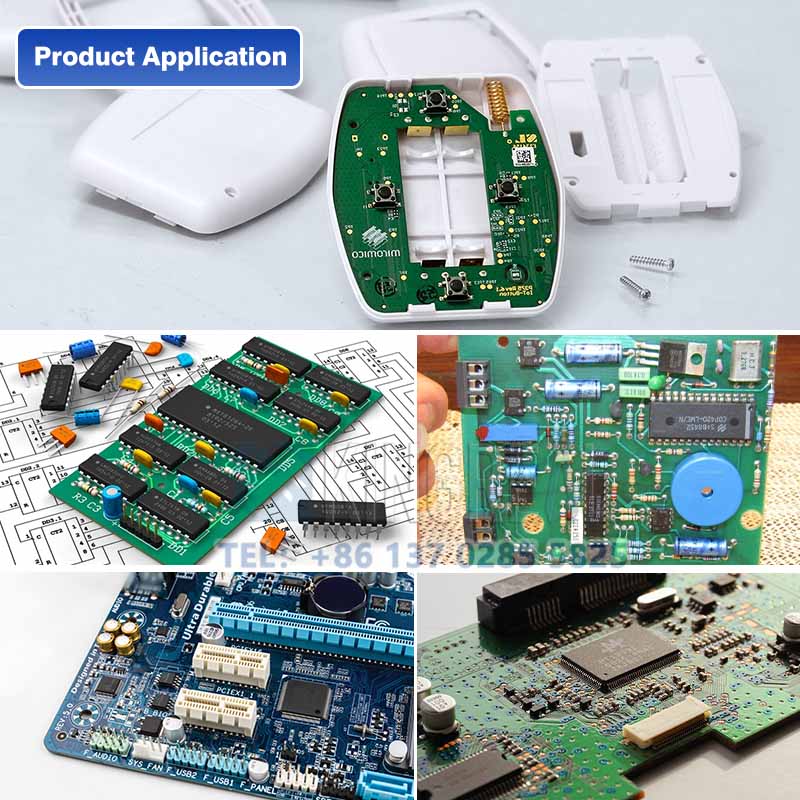

(1)Domestic appliances industry Mostly through enhancing the product's texture and usefulness, In-Mold Decoration technology is used in the household appliance sector. By means of the IMD Injection Molding process, the control panel, shell, and other components of household appliance goods can attain the decorative effect of three-dimensional patterns and simultaneously possess wear resistance, scratch resistance, chemical corrosion resistance, etc., so enhancing the product's aesthetics and endurance. Data reveals that the sales of home appliances employing In-Mold Decoration technology on the market are roughly 20% greater than those of conventional technology goods, indicating that consumers clearly prefer the fine quality appearance provided by IMD Injection Molding. |  |

In-Mold Decoration technology is extensively utilized in the production of shells and buttons of cellphones, tablets, ebook readers and other devices in the electronics sector. Maintaining their lightness and toughness, the IMD Injection Molding technique allows the shells of these goods to exhibit more vivid hues and patterns. For instance, its product return rate dropped by 30% and user happiness rose by 25% after a well-known brand of mobile phones adopted the In-Mold Decoration process. Moreover, the IMD Injection Molding technique enables the customized tailoring of electronic goods and meets the different demands of the market. |  |

IMD Injection Molding is mostly used in the automotive sector in the production of interior components including instrument panels, air conditioning panels, inner panels, among others. In addition to increasing the aesthetic appeal of vehicle interiors, In-Mold Decoration technology also increases the durability and scratch resistance of the interior. Feedback from car manufacturers indicates that using IMD Injection Molding, the production cost of internal components is 15% less than that of conventional techniques, and the market competitiveness of products has grown by roughly 10%. The In-Mold Decoration also helps to responsibly recycle vehicle interior components, so fulfilling the current demands of the automobile industry for sustainable growth. |  |