KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825In today's rapidly developing manufacturing industry, IMD injection molding process is gradually becoming an important means of surface decoration and functional realization of plastic products with its unique charm and wide application fields. In this article, KRMOLD will deeply explore the definition, principle, advantages, application and future development trend of in-mold decorating process, aiming to provide you with a detailed and practical technical guide.

| 1 | Overview of In-mold Decorating Basics Process |

| 2 | Principle and Process of In-mold Decorating Process |

| 3 | Advantages of IMD Injection Molding Process |

| 4 | Application Cases of In-mold Decorating Basics Process |

| 5 | Future Development Trend of In-mold Decorating Process |

1. Overview of In-mold Decorating Basics Process

2. Principle and Process of In-mold Decorating Process

2.1 Principle of in-mold decorating basics

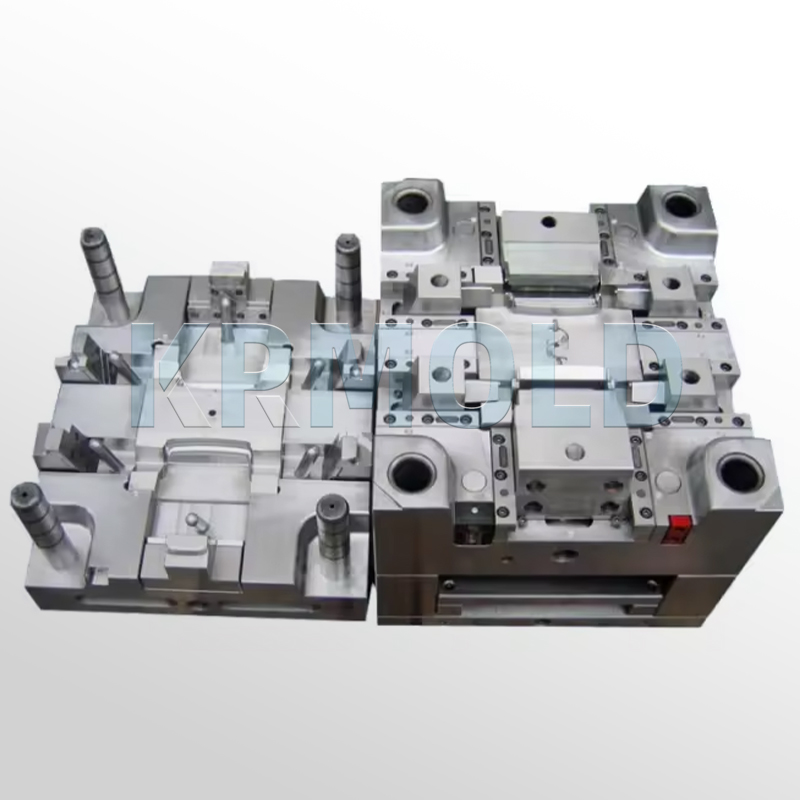

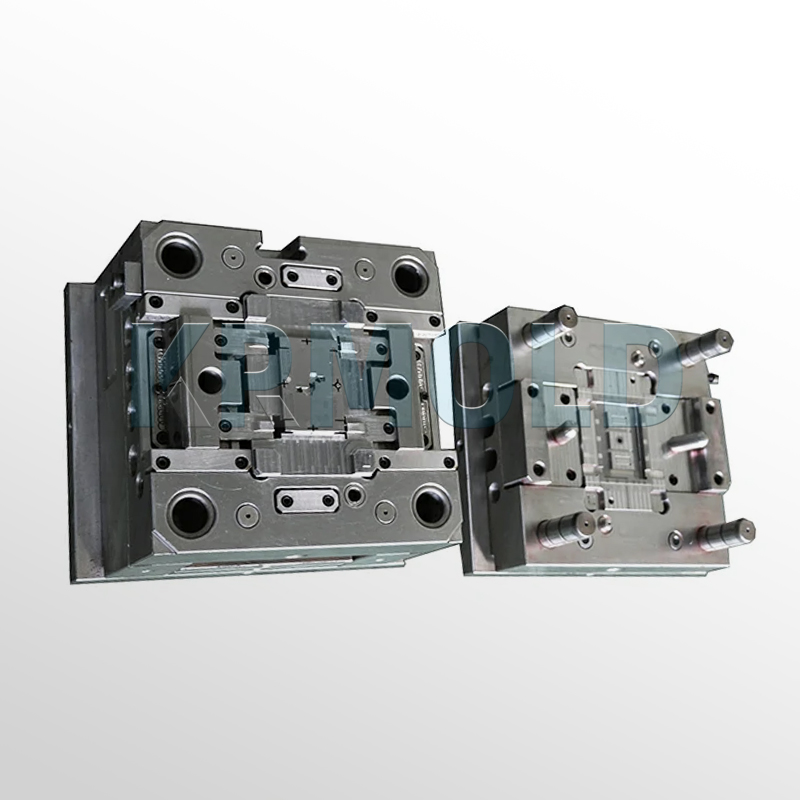

The core of the in-mold decorating process is to print the pattern on the foil film, and then use the film feeder to fit the film into the mold cavity, and then perform injection molding. After the injection molding is completed, the ink layer with the pattern will separate from the foil film carrier and remain on the surface of the plastic part, thereby obtaining a plastic part with a decorative pattern. This process realizes the integration of injection molding and decoration, greatly improving production efficiency and product quality;

2.2 Process of in-mold decorating basics

The in-mold decorating process mainly includes the steps of preparing materials, cleaning molds, installing films, debugging equipment, injection molding, hot pressing molding, cooling demolding and post-processing. Among them, injection molding and hot pressing molding are key links, which determine the final quality and appearance of the product. By precisely controlling parameters such as temperature, pressure and time, the close adhesion of the film and plastic, as well as the dimensional stability and surface quality of the product can be ensured.

3. Advantages of IMD Injection Molding Process

3.1 Reduce costs and time

In the in-mold decorating process, only one set of molds is needed, compared with other alternative processes that require multiple sets of molds, which greatly reduces system costs and inventory costs. At the same time, the one-time injection molding method achieves molding and decoration at the same time, simplifies the production process, shortens the product manufacturing cycle, and improves production efficiency;

3.2 Product stability and durability

Since the ink is between the sheet and the in-mold decorating basics material, three-dimensional molding increases the freedom of design. Graphics and colors are in the plastic interlayer, which is wear-resistant and corrosion-resistant, and the colors are bright, and the printed patterns can be changed at any time without changing the mold. This makes IMD products extremely stable and durable, and can meet the use requirements in various harsh environments;

3.3 3D complex shape design and diversified styles

In-mold decorating technology supports the design of 3D complex shapes and the realization of diversified styles. Patterns, colors, fonts, LOGO, etc. can be silk-screened or screen-printed on sheets and then molded into 3D shapes. This flexibility enables IMD products to create special styles such as metal plating or natural materials according to customer needs, meeting the personalized needs of different industries and markets.

4. Application Cases of In-mold Decorating Basics Process

Application

In automobile interior manufacturing, in-mold decorating process has been widely used. By placing a film in the automobile interior mold and then injecting plastic melt, high-quality, wear-resistant, anti-fingerprint and easy-to-clean automobile interior parts can be manufactured. Such as instrument panels, door panels, seats and other parts, not only improve the beauty and service life of automobile interiors, but also simplify the production process and reduce costs;

Household appliance manufacturing is also one of the important application areas of in-mold decorating basics. By placing a film in a household appliance mold and injecting plastic melt, household appliance parts with high-quality and anti-fingerprint surfaces can be manufactured, such as the shells of rice cookers, induction cookers and air conditioners. This process improves the appearance quality and user experience of household appliances, while enhancing the durability and scratch resistance of the products;

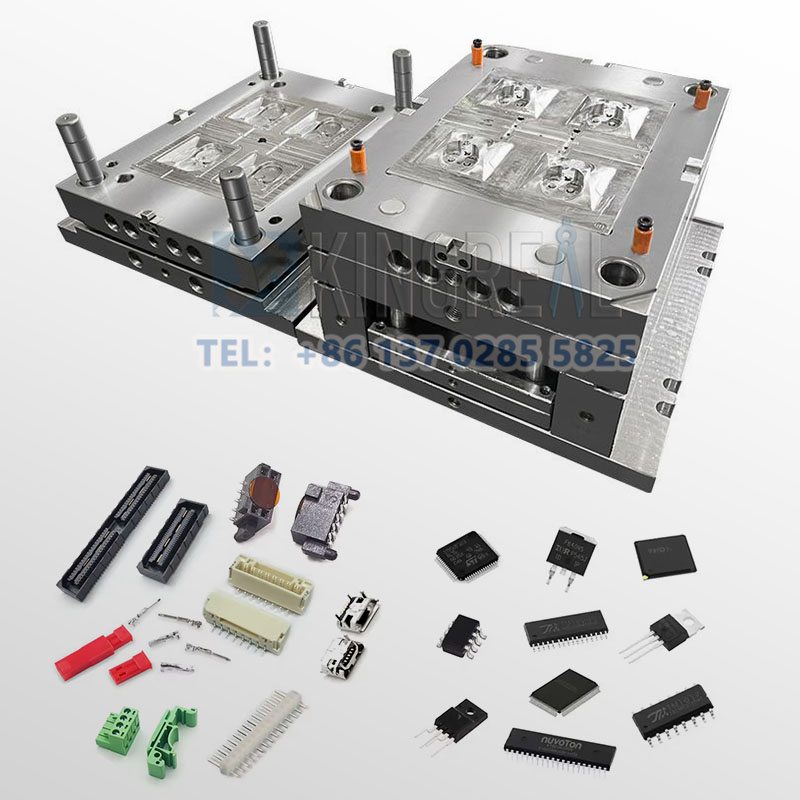

In the field of communications and electronic product manufacturing, in-mold decorating technology also plays an important role. For example, in the production of components such as mobile phone shells/lenses, MP3/MP4 signs, digital cameras and other signs, the in-mold decorating basics process can achieve rapid prototyping and efficient production, while giving the product excellent appearance and durability. This makes electronic products more beautiful, durable and in line with the aesthetic needs of modern consumers.

5. Future Development Trend of In-mold Decorating Process

With the advancement of science and technology and the development of manufacturing industry, IMD injection molding process will continue to usher in new challenges and opportunities.

On the one hand, as consumers' requirements for product appearance and performance continue to increase, in-mold decorating basics needs to be continuously innovated and improved to meet market demand; on the other hand, with the enhancement of environmental awareness and the popularization of the concept of sustainable development, in-mold decorating technology also needs to develop in a more environmentally friendly and energy-saving direction. In the future, IMD injection molding technology will pay more attention to the development and innovation of material selection and recycling, energy conservation and emission reduction in the production process, and product recycling.

In summary, in-mold decorating basics plays an increasingly important role in the manufacturing industry with its unique advantages and wide application fields. By deeply understanding the principles, processes, advantages and application cases of in-mold decorating technology, we can better grasp the development trend and market prospects of this technology. I believe that in the future development, IMD injection molding technology will continue to lead the innovation trend of the manufacturing industry and create a better future for human society.