KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | KRMOLD Doorbell Plastic Cover Shell Injection Mould Making Solutions |

| 2 | Doorbell Plastic Cover Shell Injection Mould Quality |

| 3 | Doorbell Plastic Cover Shell Injection Mold Manufacturing Process |

| 4 | Parameters of Video Door Bell Plastic Injection Mold |

| 5 | KRMOLD Video Door Bell Plastic Injection Mold Manufacturing Technology Strength |

| 6 | Plastic Smart Doorbell Installation Precautions |

As a plastic injection mold manufacturer with over 20 years of manufacturing experience, KRMOLD specializes in doorbell plastic cover shell injection mould, providing efficient and precise solutions. This article will delve into KRMOLD expertise and advantages in manufacturing video door bell plastic injection mold.

1/ KRMOLD Doorbell Plastic Cover Shell Injection Mould Making Solutions

KRMOLD underlines technical communication and analysis with clients during the creation of video door bell plastic injection molds.

This important stage guarantees the viability and correctness ofthe ultimate design. KRMOLD will completely grasp the customer's needs throughout the communication with him, including important elements like the doorbell's design, practical needs, and production volume.

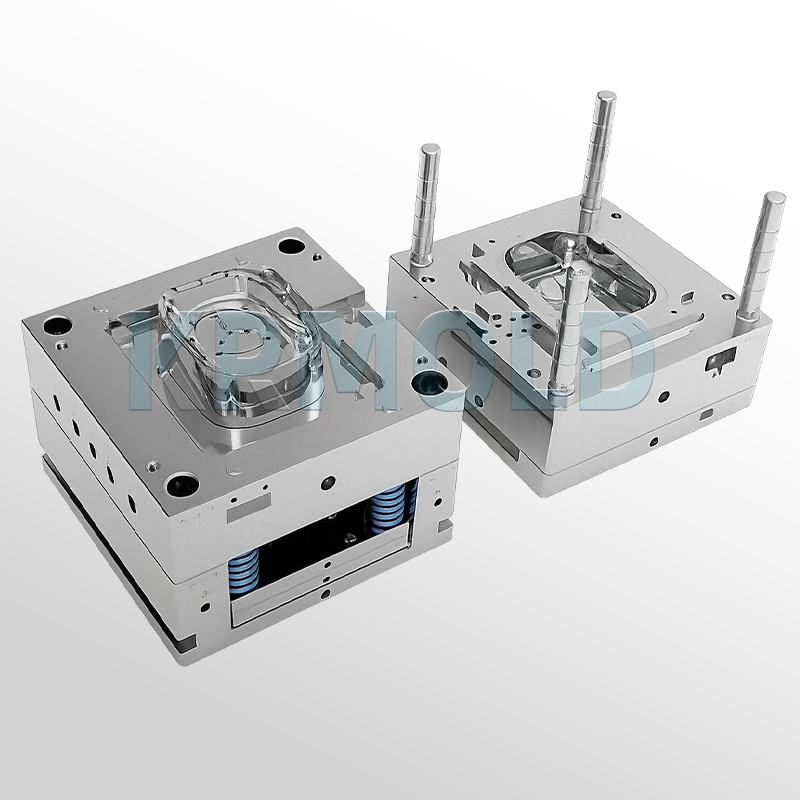

Once the design is approved, KRMOLD will move on to doorbell shell plastic injection mould production and testing. Three-dimensional printing prototypes, video door bell plastic injection mold production, assembling, commissioning define this process.

2/ Doorbell Plastic Cover Shell Injection Mould Quality

KRMOLD prioritizes mold quality and is committed to producing high-precision doorbell shell. Each video door bell plastic injection molds housing details are meticulously designed to ensure clear visibility, no watermarks, and no sharp edges. After assembly, the step difference is controlled within 0.04mm, ensuring a smooth feel and a seamless feel. This high standard of quality control not only enhances the product's aesthetics but also greatly increases the doorbell's durability.

3/ Doorbell Plastic Cover Shell Injection Mold Manufacturing Process

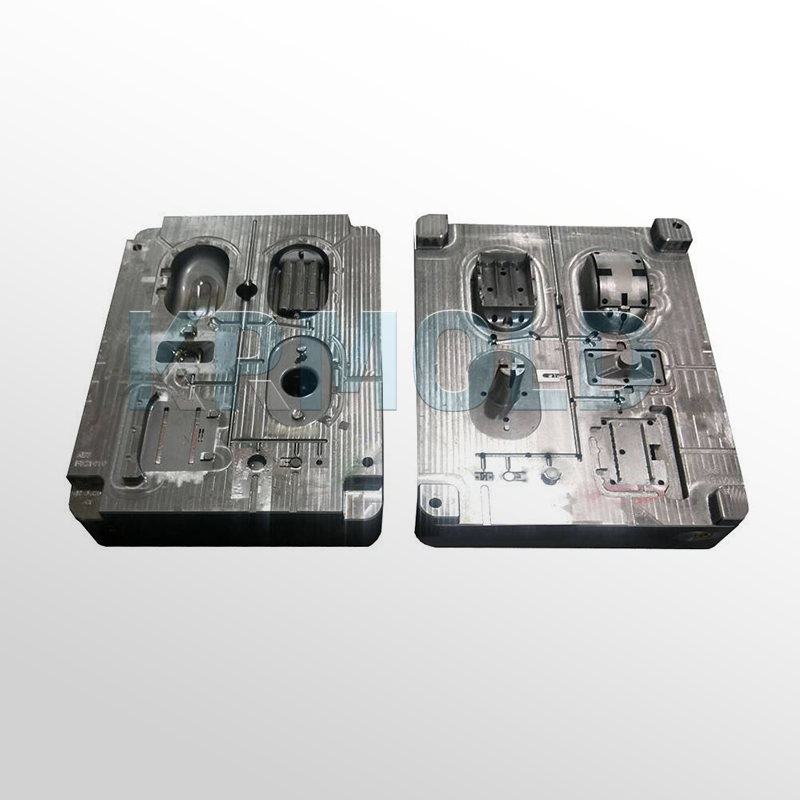

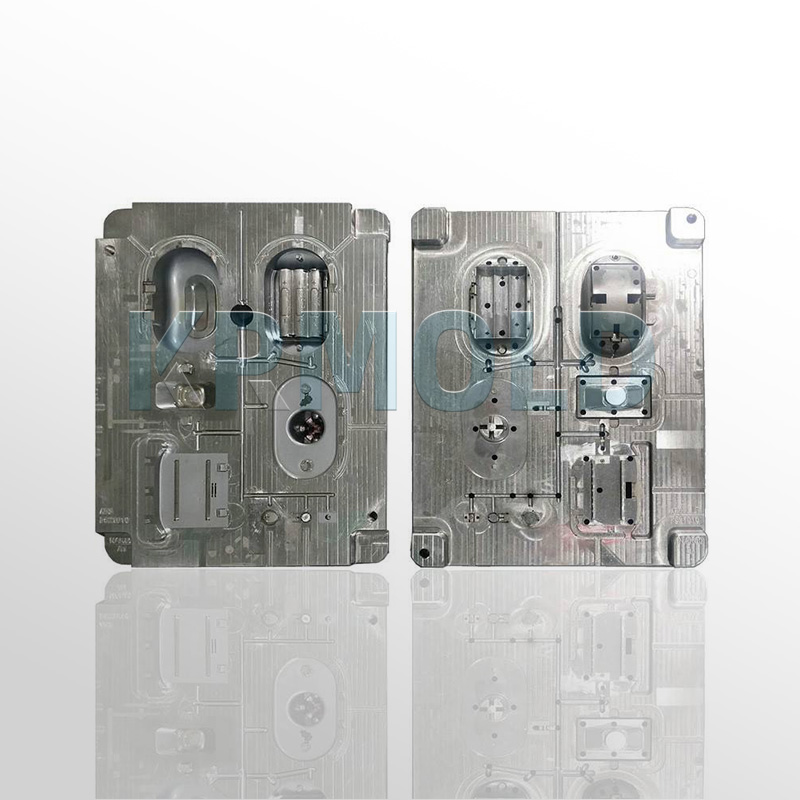

Video door bell plastic injection molds are specialized molds used to produce doorbell plastic cover shell.

Usually built of premium steel, these shapes and sizes suit doorbell.The production process comprises several stages, all of which are vital.

(1)Design phase of video door bell plastic injection mold

Before manufacturing begins, KRMOLD first designs a suitable doorbell plastic cover shell injection mold drawing. This design phase considers many criteria, including the doorbell's appearance, usability, and simplicity of usage.Once the design is finished, the correct material is chosen depending on the drawing for further processing.

(2)Processing phase of video door bell plastic injection mould

KRMOLD cuts and turns steel during processing using CNC equipment.High precision equipment guarantees that the form and dimension of the part satisfy the design specs.At this point, the manufacturing crew performs strict quality checks on every part to make sure it satisfies requirements.

(3)Assembly and welding of doorbell plastic cover shell injection mold

Following processing is the components assembly stage.Welding or melting fasteners helps components to be structurally stable.The assembled mold is polished to produce a smoother and more polished finish, which helps to make the injection molding procedure easier as well as improve the look.

(4)Testing phase of video door bell plastic injection mold

KRMOLD tests the newly produced doorbell plastic cover shell injection mould very after polishing and assembly.This stage guarantees that every component of the video door bell plastic injection mould satisfies requirements.The production team swiftly changes and repairs any problems found; only after passing all pertinent inspections can the doorbell plastic cover shell injection mould be utilized.

(5)Injection molding process

KRMOLD pours liquid plastic into the video door bell plastic injection mould and uses suitable pressure to fill the cavities once the doorbell plastic cover shell injection mould is ready.The video door bell plastic injection mould can be taken apart once the plastic hardens to expose the finished product—the doorbell plastic cover shell.

4/ Parameters of Video Door Bell Plastic Injection Mold

The selection of process parameters is crucial in the manufacture of doorbell plastic cover shell injection mould for doorbell shell. The following are some of the key process parameters used by KRMOLD:

| Glue feeding method: | Large nozzle to submersible |

| Ejection method: | Ejector |

| Number of ejection molds: | 1+1 |

| Mold material: | 718H |

| Plastic material: | ABS |

| Surface treatment: | Polished |

| Customization: | Yes |

5/ KRMOLD Video Door Bell Plastic Injection Mold Manufacturing Technology Strength

KRMOLD not only possesses advantages in manufacturing technology but also possesses comprehensive infrastructure. The company is furnished with several specialized workshops—including a quality control center, CNC workshop, EDM workshop, mold trial workshop, raw material workshop, video door bell plastic injection mold making workshop, assembly workshop, rough machining workshop, wire cutting shop, design studio, and polishing facility—across a big area.Ensuring product quality, these thorough amenities let KRMOLD effectively design, produce, and test doorbell plastic cover shell injection mould.

6/ Plastic Smart Doorbell Installation Precautions

During the installation process, please note the following points to ensure proper operation of your smart doorbell:

-Transmitter Location: Avoid mounting the transmitter on a metal door, as metal can reduce signal transmission distance.

-Receiver Location: Keep the receiver away from electrical appliances with high electromagnetic radiation, such as appliances, speakers, and computers, to avoid signal interference.

-Remote Control Distance: The actual remote control distance may be affected by environmental factors, so consider the surrounding environment when selecting the installation location.